Environment-friendly straw recycling efficient treatment system

A straw resource and processing system technology, applied in chemical instruments and methods, filters, grills, etc., can solve problems such as poor working environment for workers, straw falling out, and machine jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

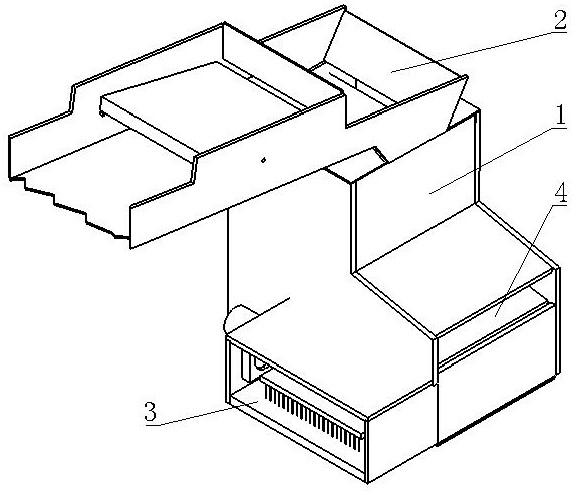

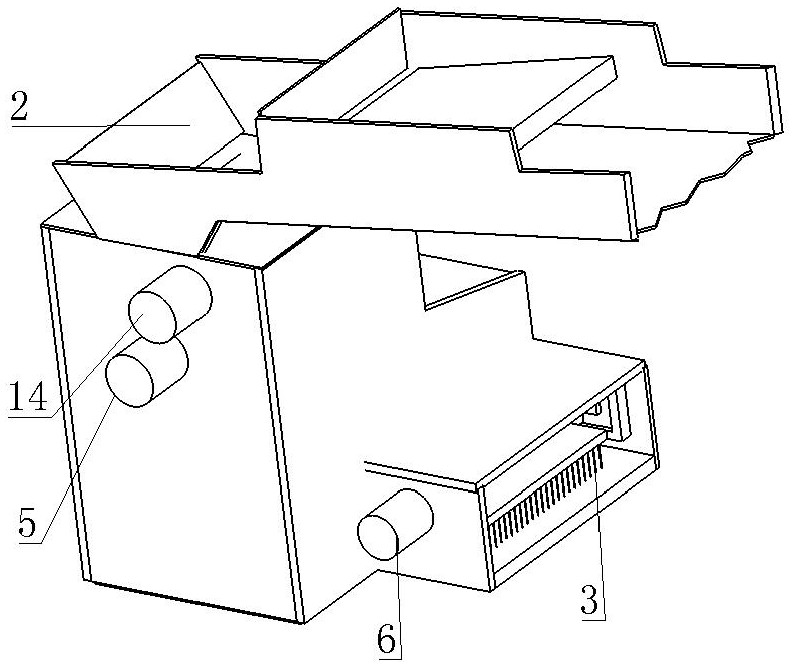

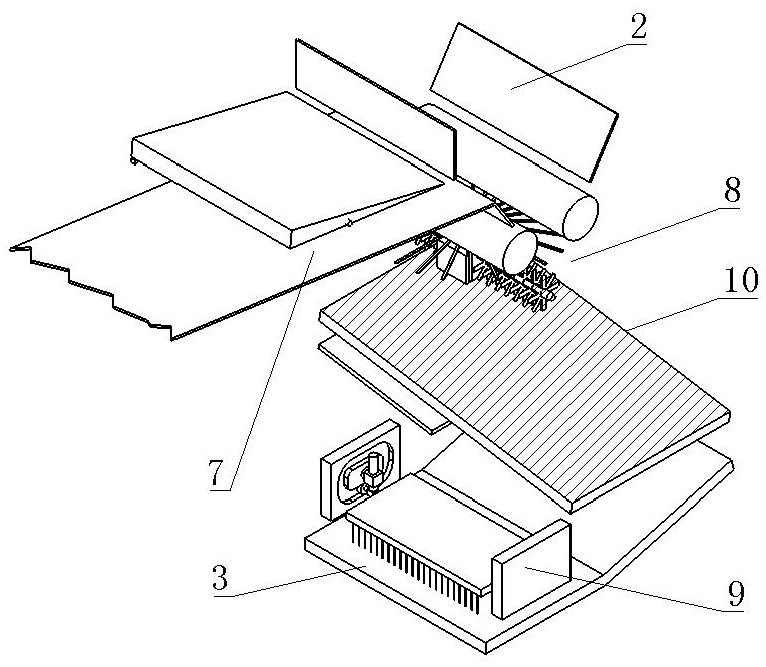

[0046] An environment-friendly straw resource efficient treatment system, such as figure 1 , figure 2 , image 3 As shown, a housing 1 is included, and a feeding device 7 is arranged in the housing 1, and a feeding port 2 matched with the feeding device 7 is provided on one side of the feeding device 7; a pair of feeding devices are arranged below the feeding port 2 The feed roller is connected with a motor, and the gap between the feed rollers is connected to the feed port 2; a cutting device 8 is arranged below the feed roller, and the cutting device 8 matches the gap between the feed rollers; A vibrating screen 10 is arranged below the material cutting device 8, and the gap between the vibrating screen 10 and the feeding roller is matched; the first discharge port 4 and the second discharge port that are matched with the vibrating screen 10 are opened on the shell 1 3. The first discharge port 4 communicates with the top of the vibrating screen 10, and the second dischar...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 lies in that a second limiting block 706 is fixedly connected to the side plate.

[0057] Such as Figure 12 As shown, the second limit block 706 is arranged below the feeding section of the material holding plate 701. When the lower feeding section rotates downward, the second limit block 706 limits the position of the feeding section to prevent the material holding plate 701 from wearing the conveyor belt. 704.

Embodiment 3

[0059] The difference between this embodiment and Embodiment 1 is that a water distribution pipe is arranged in the kneading plate 901 .

[0060] Such as Figure 13 As shown, a cooling water pipe is arranged in the kneading material plate 901 to prevent the frictional overheating of the kneading material plate 901. 15 and the water outlet pipe 16, the water inlet pipe 15 and the water outlet pipe 16 are flexible pipes, and the housing 1 is provided with a through hole above the kneading material plate 901.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com