Preparation method of Huangshan tablet tea

A production method and technology of sliced tea, applied in manufacturing tools, pre-extraction tea treatment, laser welding equipment, etc., can solve the problems of waste of mature leaf resources, bitterness and astringency, etc., and achieve low cost, high added value, and good taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of Huangshan sliced tea, is raw material with the ripe leaf in the tea garden, comprises the steps:

[0025] S1. Recycling raw materials: collecting mature and complete leaves from the pruned branches of the tea garden.

[0026] S2. Steaming greens: first, keep the collected mature leaves in warm water at 38°C for 180s; then quickly place them in a green steaming machine for steaming greens.

[0027] S3. Rapid cooling at low temperature: quickly immerse the steamed leaves in cold water at 10° C. for 5 seconds.

[0028] S4, film brushing: take the leaves out of cold water, then brush off the film on the surface of the leaves with a brush, then rinse and dry until the water content of the leaves is 30% to 35%.

[0029] S5. Flattening: the dried leaves are flattened, and the pressure is controlled at 20N until the water content of the leaves drops to 20%.

[0030] S6. Engraving: Engraving the surface of the flattened leaves, and then drying...

Embodiment 2

[0032] A kind of preparation method of Huangshan sliced tea, is raw material with the ripe leaf in the tea garden, comprises the steps:

[0033] S1. Recycling raw materials: collecting mature and complete leaves from the pruned branches of the tea garden.

[0034] S2. Steaming green: first keep the collected mature leaves in warm water at 37°C for 200s; then quickly place them in a green steaming machine for steaming. The steaming temperature is set at 100°C for 120s.

[0035] S3. Rapid cooling at low temperature: quickly immerse the steamed leaves in cold water at 5° C. for 8 seconds.

[0036] S4, film brushing: take the leaves out of cold water, then brush off the film on the surface of the leaves with a brush, then rinse and dry until the water content of the leaves is 30% to 35%.

[0037] S5. Flattening: the dried leaves are flattened, and the pressure is controlled at 10N until the water content of the leaves drops to 25%.

[0038] S6. Engraving: Engraving the surface...

Embodiment 3

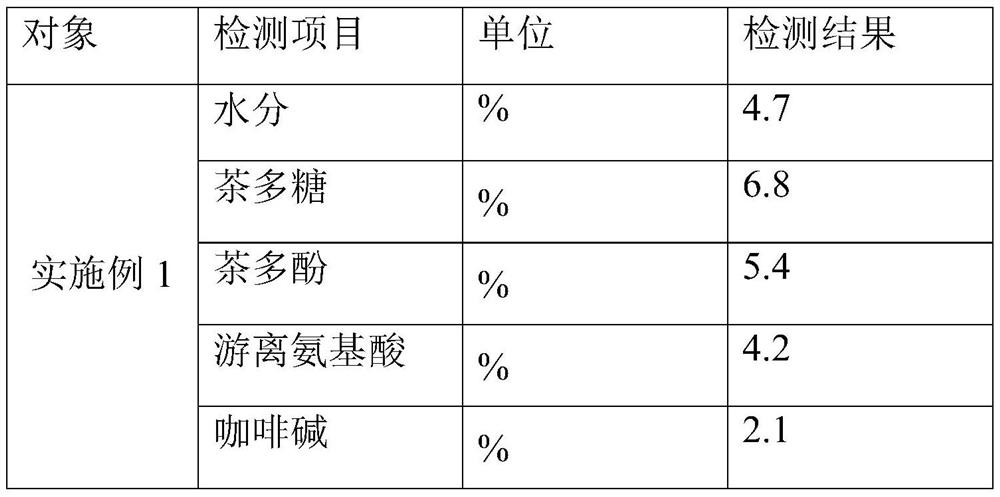

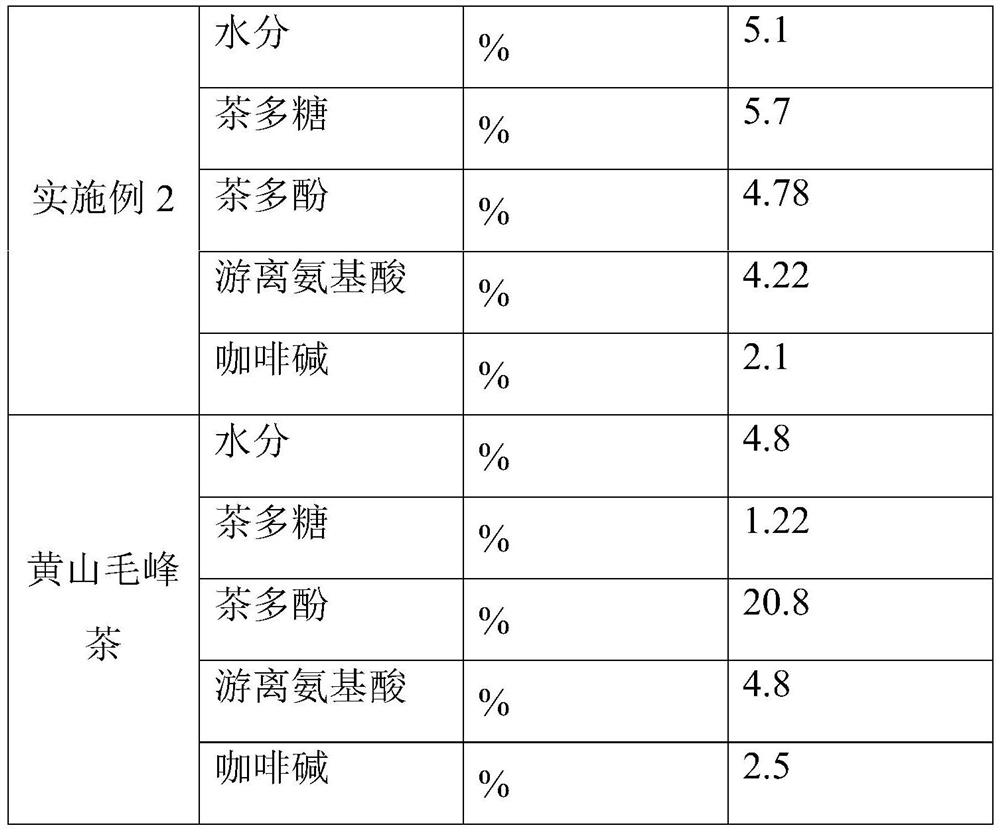

[0040] The following table shows the comparison of the detection results of Examples 1 to 2 and Huangshan Maofeng tea.

[0041]

[0042]

[0043]In summary, it can be seen from the above table that the tea polysaccharide content of the Huangshan flake tea prepared by the present invention is significantly higher than that of the traditional Huangshan Maofeng tea, and the tea polyphenol content is obviously lower than that of the traditional Huangshan Maofeng tea, so it has good taste and good taste. Bitter goodness, suitable for young people to drink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com