Preparation method of novel composite loose nanofiltration membrane

A nanofiltration membrane and loose technology, applied in the field of membrane separation, can solve the problems of difficult to control the surface charge of the membrane, insufficient uniformity, high rejection rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

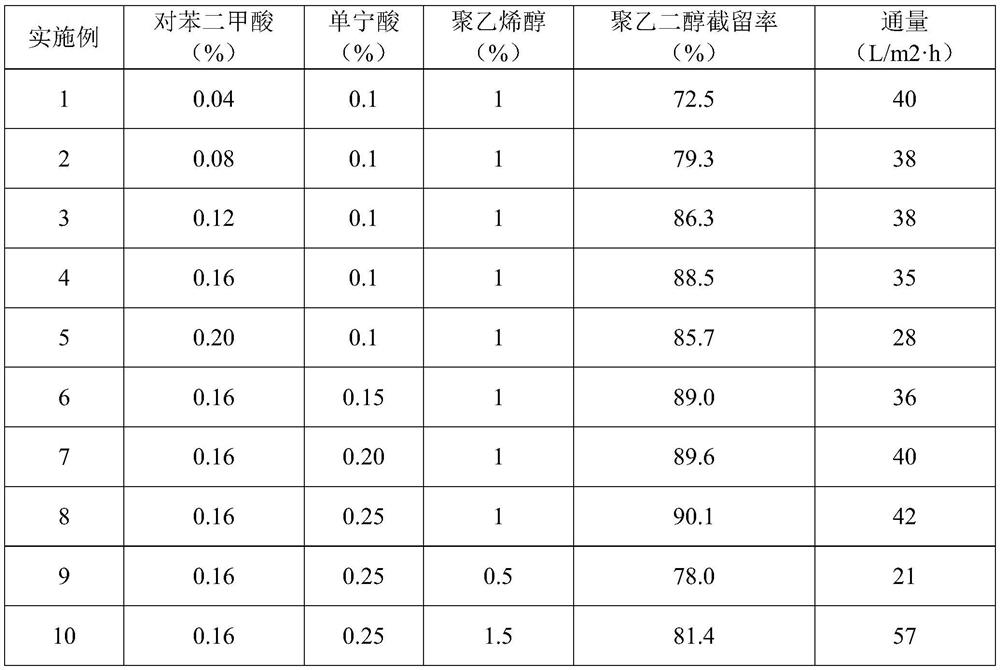

[0026] Select the 50000 molecular weight cut-off ultrafiltration membrane that polypropylene material is made for use as base membrane, prepare composite loose nanofiltration membrane according to the step described in claim 1:

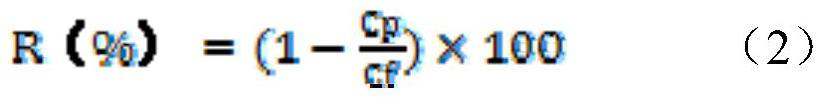

[0027] 0.04%, 0.08%, 0.12%, 0.16%, 0.20%wt of terephthalic acid compound and 0.1%, 0.15%, 0.2%, 0.25%wt of tannic acid were added to the sodium hydroxide solution whose pH was 8.5 , add 0.1% sodium lauryl sulfate, mix uniformly by magnetic stirring or ultrasonic vibration, and complete the configuration of the monomer solution; add 0.5%, 1%, 1.5%wt polyvinyl alcohol (molecular weight 67000) Mix in pure water evenly by magnetic stirring or ultrasonic oscillation to complete the configuration of the polymer solution; immerse the base film in the prepared monomer solution at 0.1MPa for 15 minutes, then pour out the monomer solution to remove excess surface Liquid, then impregnate the base film in the prepared polymer solution for 15 minutes for cross-lin...

Embodiment 11-13

[0031] The difference from Example 8 is that trimesic acid is used instead of terephthalic acid as a monomer, and the added mass fractions are 0.12%, 0.16%, and 0.20%, respectively, as shown in Table 2.

[0032] Table 2 embodiment 11-13 product is to the retention effect and flux data of the 1000 molecular weight polyethylene glycol aqueous solution of 100mg / L

[0033]

Embodiment 14-15

[0035] The difference from Example 8 is that polyethylene glycol (molecular weight 4,000,000) is used instead of polyvinyl alcohol (molecular weight 67,000) as a water-soluble polymer, and the added mass fractions are 0.5% and 1% respectively

[0036] Table 3 embodiment 14-15 product is to the retention effect and the flux data of the 1000 molecular weight polyethylene glycol aqueous solution of 100mg / L

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com