Casting mold of aluminum hub and casting method thereof

A technology for casting molds and aluminum wheels, which is applied in the field of casting molds and aluminum wheels for aluminum wheels, can solve problems such as poor product performance, sticking sand, wasting materials, and cutting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

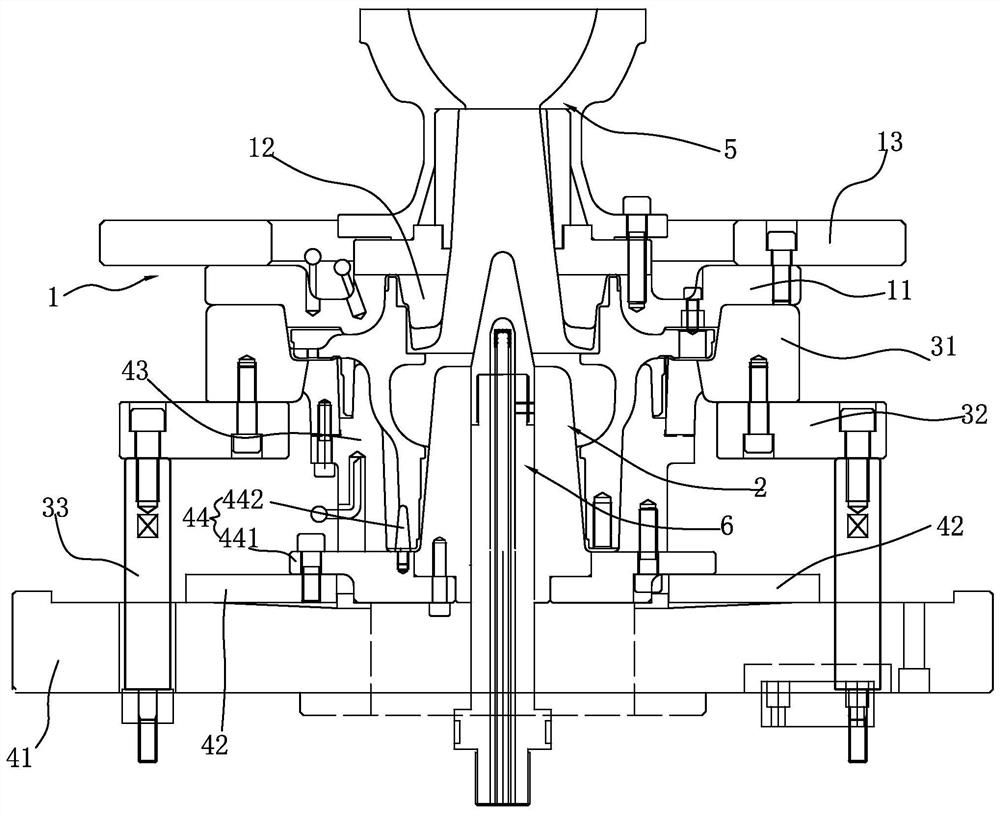

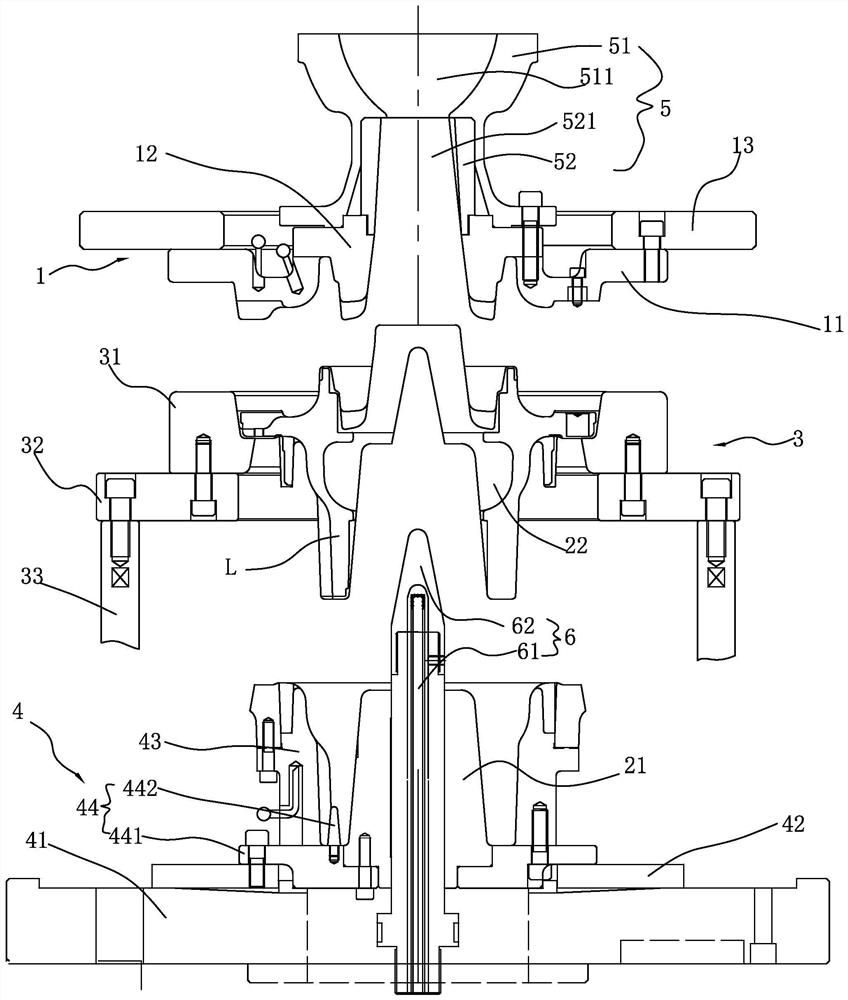

[0048] like figure 1 and image 3 As shown in the casting mold of the aluminum wheel hub, the upper mold assembly 1 includes an upper mold 11, an upper mold core 12 and an upper connecting plate 13, and the upper mold 11 is fixedly connected to the upper mold core 12 and the upper connecting plate 13 by bolts respectively.

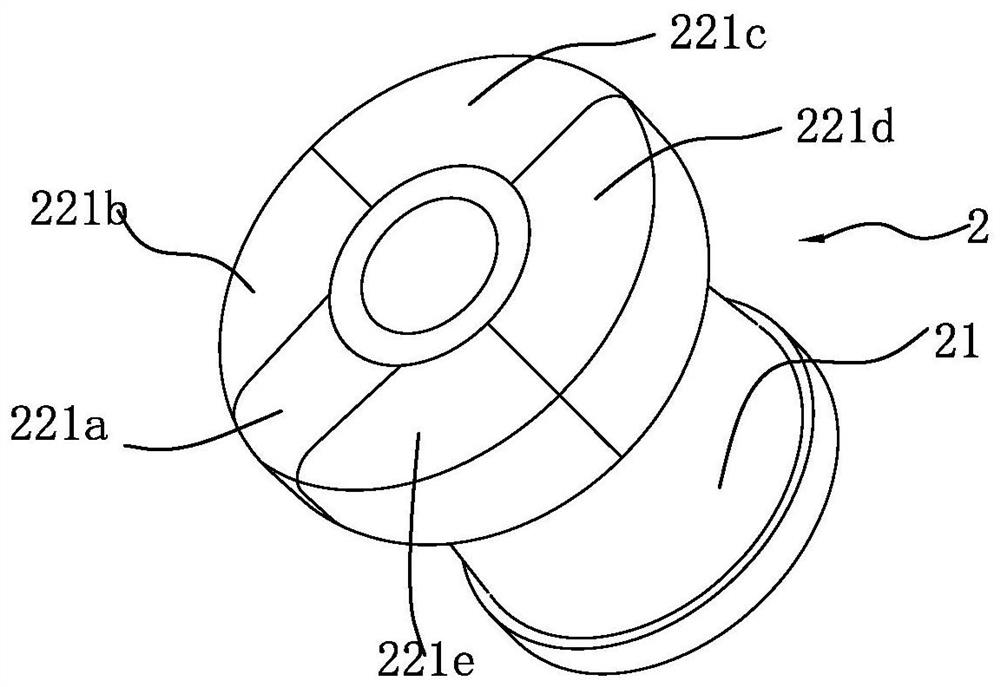

[0049] The mandrel assembly 2 includes an intermediate mandrel 21 and a mandrel ring 22, the mandrel ring is used to form the oil cavity of the hub blank L, and the mandrel ring 22 consists of a plurality of slider core modules 221 distributed circumferentially around the middle mandrel 21 Formed, the slider core module 221 is detachably connected to the middle core mold 21;

[0050] The auxiliary molding assembly 3 includes a push-out ring 31 and an ejector plate 32, and the push-out ring 31 and the ejector plate 32 are fixedly connected;

[0051] The lower mold assembly 4 comprises a base plate 41, a lower template 42, a lower mold 43, and a lower mold...

Embodiment 2

[0076] The difference between embodiment two and embodiment one is:

[0077] The structure of core mold assembly 2 is slightly different, such as Figure 6 to Figure 8 Commonly shown, the top of the middle mandrel 23 is provided with a plurality of insertion grooves 231 arranged at intervals, and the plurality of insertion grooves 231 are evenly distributed along the circumference of the top of the middle mandrel 23, and each slider core module is provided with radially To the protruding radial plug connector, the radial plug connector fits into the socket slot. In this embodiment, the top of the middle mandrel 23 is provided with five insertion slots arranged at intervals, which are respectively in the clockwise direction: the first slider core module 241a, the second slider core module 241b, the third slider core module The block core module 241c, the fourth slider core module 241d and the fifth slider core module 241e, the corresponding radial plug connectors are the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com