Porcelain plate with glittering grain effect and manufacturing method thereof

A manufacturing method and crystal grain technology, which is applied in the field of ceramic building decoration materials, can solve the problems of poor realization of physical and chemical properties, lack of layered and three-dimensional visual effects, and difficult realization of crystal grain flashing effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

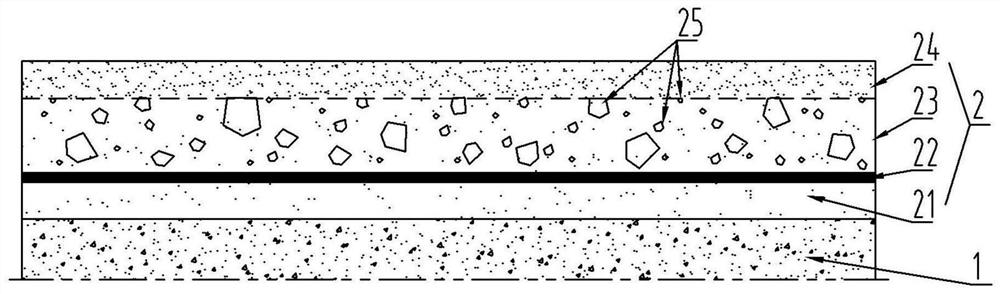

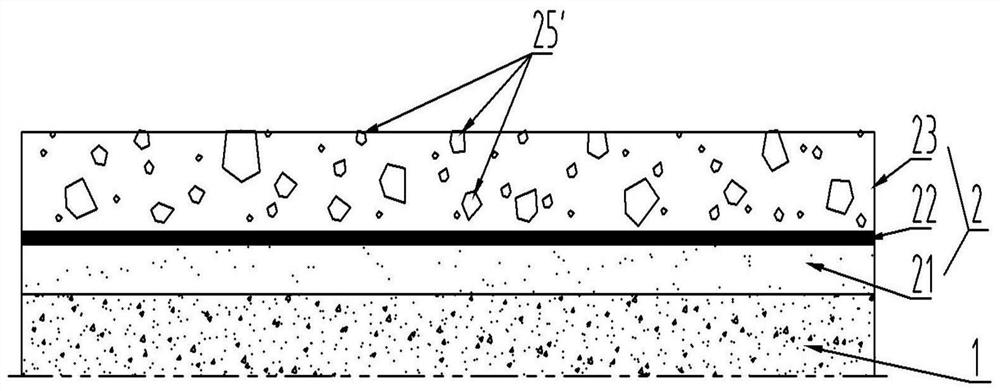

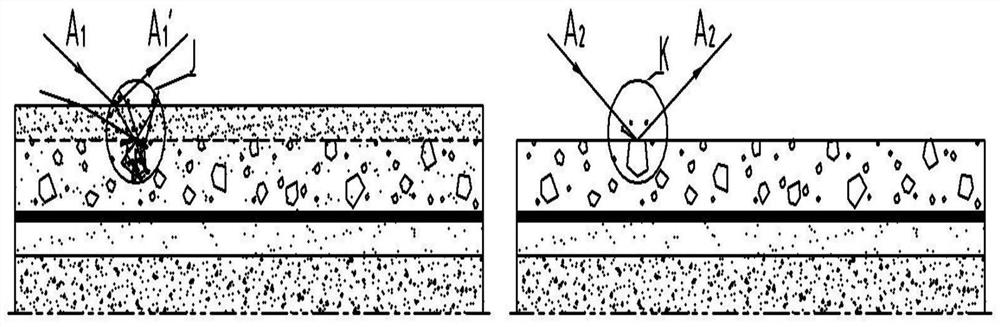

[0051] Such as figure 1 As shown, a porcelain plate with flashing grain effect includes a bottom base and a base surface decorative layer, and the base surface decoration layer sequentially includes a bottom glaze layer, a pattern layer, a protective layer, a flashing grain layer and a transparent layer, and the base glaze The layer is connected to the bottom blank.

Embodiment 2

[0053] This embodiment discloses a method for preparing a porcelain plate with flashing grain effect, which includes the following steps:

[0054] Preparatory work, including the following:

[0055] Prepare the bottom glaze, its chemical composition is by mass percentage: silicon dioxide 55.8%, aluminum oxide 32.6%, calcium oxide 0.96%, magnesium oxide 0.36%, sodium oxide 2.98%, potassium oxide 4.84%, zinc oxide 0.02%, barium oxide 0.11%, 0.19% titanium oxide, and the rest are ignition loss and trace substances, which are reserved;

[0056] Prepare mixed dry granular glaze, its composition is by mass percentage: mixed dry granular 46%, suspending agent 46%, cosolvent 8% are mixed and prepared to prepare mixed dry granular glaze, standby, wherein mixed dry granular is made of flashing grain It is mixed with transparent dry granules at a ratio of 1:3. The chemical composition of transparent dry granules is as follows: 59.2% silicon dioxide, 7.8% aluminum oxide, 6.7% potassium o...

Embodiment 3

[0069] This embodiment discloses a method for preparing a porcelain plate with flashing grain effect, which includes the following steps:

[0070] Preparatory work, including the following:

[0071] Prepare the bottom glaze, its chemical composition is by mass percentage: silicon dioxide 55.8%, aluminum oxide 32.6%, calcium oxide 0.96%, magnesium oxide 0.36%, sodium oxide 2.98%, potassium oxide 4.84%, zinc oxide 0.02%, barium oxide 0.11%, 0.19% titanium oxide, and the rest are ignition loss and trace substances, which are reserved;

[0072] Prepare mixed dry granular glaze, its composition is by mass percentage: mixed dry granular 46%, suspending agent 46%, cosolvent 8% are mixed and prepared to prepare mixed dry granular glaze, standby, wherein mixed dry granular is made of flashing grain It is mixed with transparent dry granules in a ratio of 1:3. The chemical composition of transparent dry granules is 59.2% of silicon dioxide, 7.8% of aluminum oxide, 6.7% of potassium oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com