Preparation method of acetamide compound

A compound, acetamide technology, applied in the field of preparation of acetamide compounds, can solve problems such as the effect of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

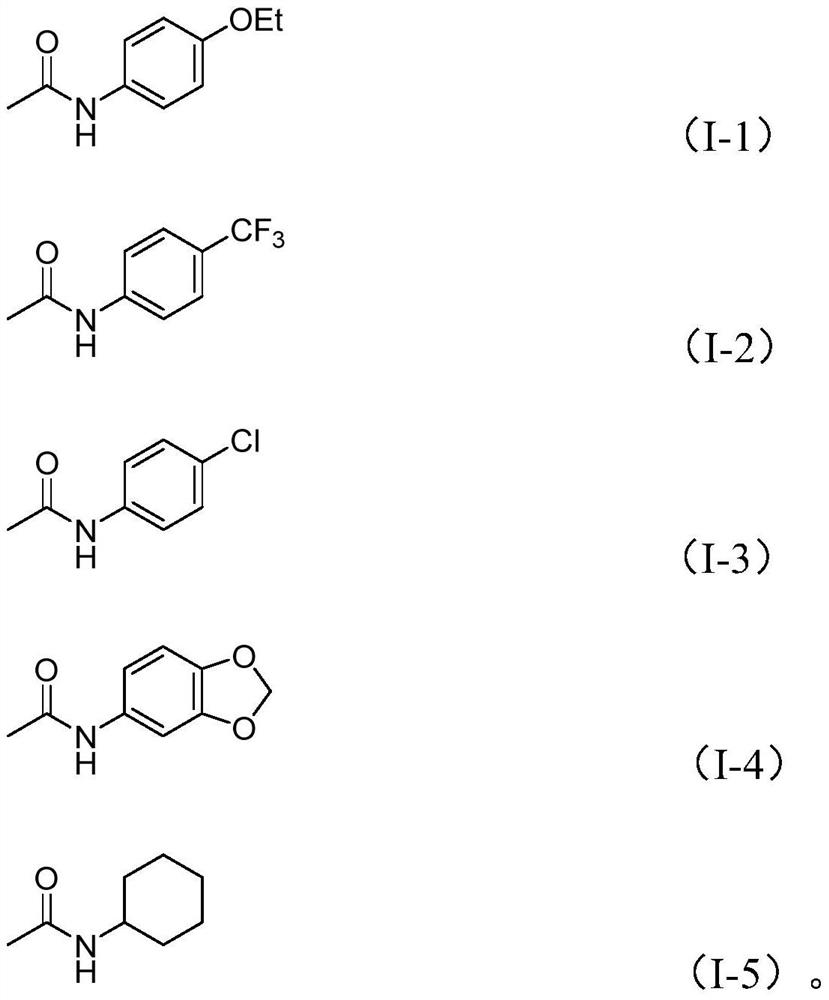

[0036] Add dirhodium tetracarbonyl dichloride, 1,3-bis(diphenylphosphine)propane (DPPP), tungsten carbonyl, sodium phosphate, sodium iodide, water, Nitro compound (II) and dimethyl carbonate (III), mixed and stirred evenly, reacted according to the reaction conditions in Table 2, after the reaction was completed, filtered, silica gel mixed sample, and purified by column chromatography to obtain the corresponding acetamide compound (Ⅰ ), the reaction process is shown in the following formula:

[0037]

[0038] The raw material addition of table 1 embodiment 1~15

[0039]

[0040] Table 2

[0041]

[0042] In Table 1 and Table 2, T is the reaction temperature, t is the reaction time, Et is ethyl, Ph is phenyl, CF 3 is trifluoromethyl, Me is methyl, SMe is methylthio, OMe is methoxy, and t-Bu is tert-butyl.

[0043] The structural confirmation data of the compounds prepared in Examples 1-5:

[0044] The nuclear magnetic resonance (NMR) of the acetamide compound (I-1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com