A kind of disulfonic acid-based surfactant, clean fracturing fluid and preparation method thereof

A surfactant and cleaning fracturing fluid technology, applied in chemical instruments and methods, organic chemistry, drilling compositions, etc., can solve the problems of high cost, poor salt resistance, complicated preparation process, etc., and achieve low cost, Excellent salt tolerance and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

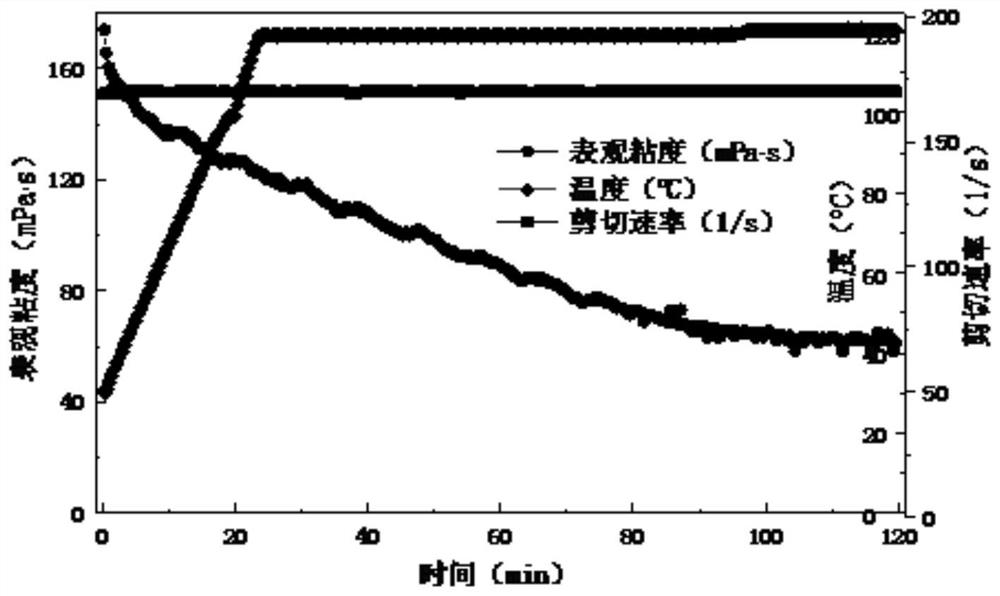

Embodiment 1

[0032] A kind of bissulfonic acid-based surfactant, clean fracturing fluid and preparation method thereof provided in this embodiment 1 specifically include the following processes:

[0033] The preparation of bissulfonic acid-based surfactant includes the following steps:

[0034] Step (1): Dissolve oleic acid amidopropyldimethyl tertiary amine (14.669g, 40mmol) and epichlorohydrin (3.7g, 40mmol) in absolute ethanol, and add hydrochloric acid (1.45g, 40mmol) , the system was always under nitrogen protection, and reacted at 50 °C for 16 hours. After the reaction, the solvent ethanol was removed with a rotary evaporator at 45 °C to obtain intermediate A, which was a pale yellow liquid;

[0035] Step (2): Add Intermediate A (51.52g, 100mmol) and piperazine-N,N'-bis(2-ethanesulfonic acid) sesquisodium salt (134.14 g) obtained in step (1) into a 100ml single-necked flask g, 200 mmol), 100 ml of ethanol was added, and the reaction was refluxed for 18 hours under the condition of 7...

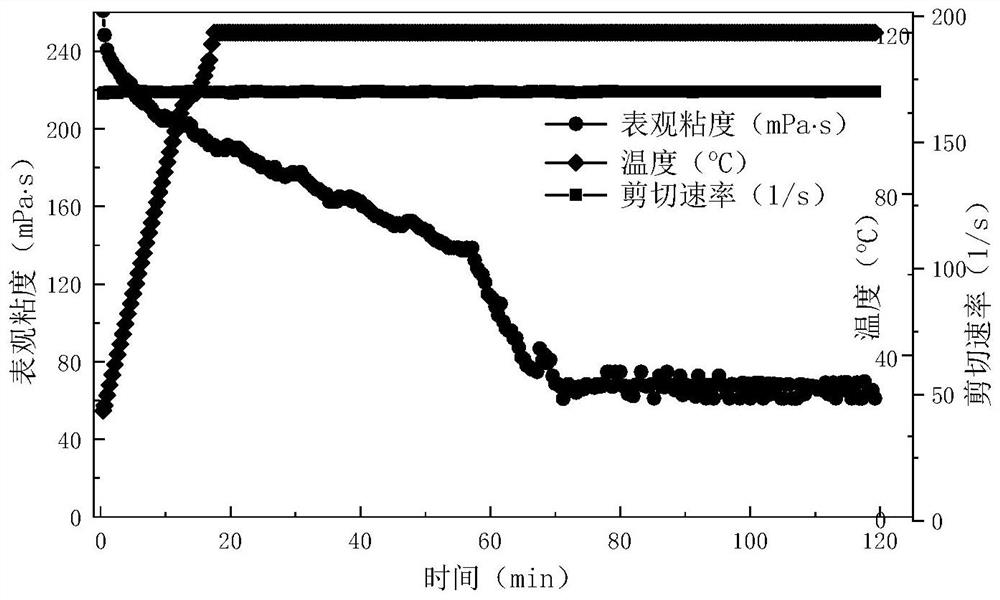

Embodiment 2

[0038] A kind of bissulfonic acid-based surfactant, clean fracturing fluid and preparation method thereof provided in this embodiment 2 specifically include the following processes:

[0039] Step (1): Dissolve erucamidopropyl dimethyl amine (16.908g, 40mmol) and epichlorohydrin (3.7g, 40mmol) in absolute ethanol, and add hydrochloric acid (1.45g, 40mmol), The system was always under nitrogen protection, and the reaction was carried out at 50 °C for 16 hours. After the reaction, the solvent ethanol was removed at 45 °C with a rotary evaporator to obtain intermediate A, which was a pale yellow liquid;

[0040] Step (2): Add Intermediate A (51.52g, 100mmol) and piperazine-N,N'-bis(2-ethanesulfonic acid) sesquisodium salt (134.14 g) obtained in step (1) into a 100ml single-necked flask g, 200 mmol), 100 ml of ethanol was added, and the reaction was refluxed for 18 hours under the condition of 70 ° C; after the reaction, the solvent ethanol was removed at 45 ° C with a rotary evapo...

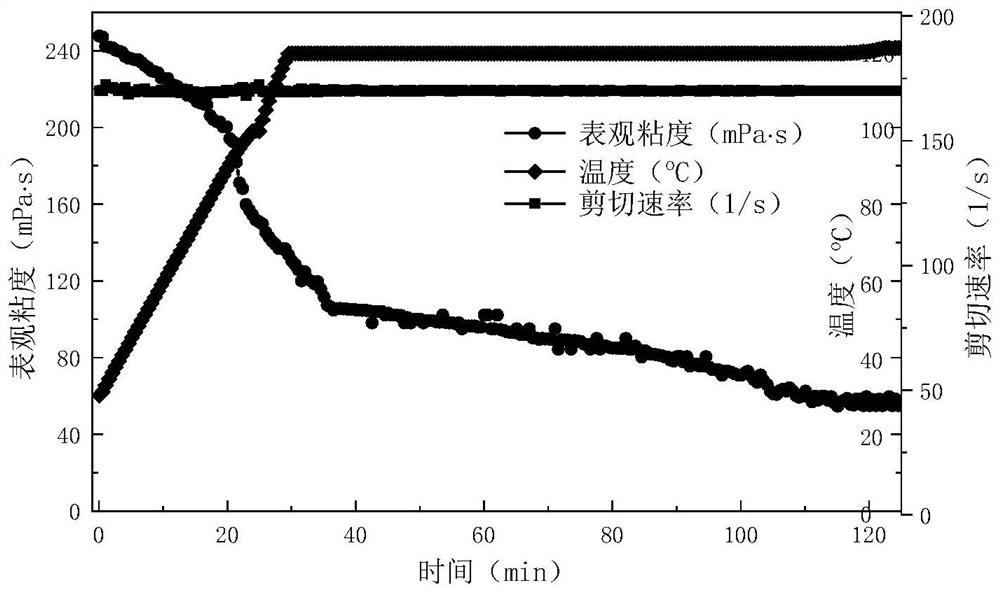

Embodiment 3

[0043] A kind of bissulfonic acid-based surfactant, clean fracturing fluid and preparation method thereof provided in this embodiment 3 specifically include the following processes:

[0044] The preparation of bissulfonic acid-based surfactant includes the following steps:

[0045] Step (1): Dissolve oleic acid amidopropyldimethyl tertiary amine (14.669g, 40mmol) and epichlorohydrin (3.7g, 40mmol) in absolute ethanol, and add hydrochloric acid (1.45g, 40mmol) , the system was always under nitrogen protection, and reacted at 50 °C for 16 hours. After the reaction, the solvent ethanol was removed with a rotary evaporator at 45 °C to obtain intermediate A, which was a pale yellow liquid;

[0046]Step (2): Add Intermediate A (51.52g, 100mmol) and piperazine-N,N'-bis(2-ethanesulfonic acid) sesquisodium salt (134.14 g) obtained in step (1) into a 100ml single-necked flask g, 200 mmol), 100 ml of ethanol was added, and the reaction was refluxed for 12 hours under the condition of 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com