Processing technology of low-static glass fiber chopped strands with good bundling property

A technology of glass fiber and processing technology, which is applied in the field of processing technology of finely bundled and low-static glass fiber chopped strands. It can solve the problems of low bundleability and difficult dispersion of finishing agents, and achieve the effect of enhancing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is the processing technology of the good bundled low-static glass fiber chopped strands, and the good bundled low-static glass fiber chopped strands are prepared by the following steps:

[0053] S1: Use sizing agent and silane coupling agent to pretreat glass fiber strands, and then use a cutting device to cut into short filaments;

[0054] S2: Use finishing agent to spray the cut filaments;

[0055] S3: performing stuffing and wake-up treatments in sequence, and finally sealing and packaging to obtain the good bundled low-static glass fiber chopped strands;

[0056] The finishing agent includes the following components in parts by weight:

[0057] 0.5 part of coupling agent, 2 parts of emulsifier, 2 parts of antistatic agent, 0.1 part of softener, 95.4 parts of non-ionic water;

[0058] The emulsifier is prepared by the following steps:

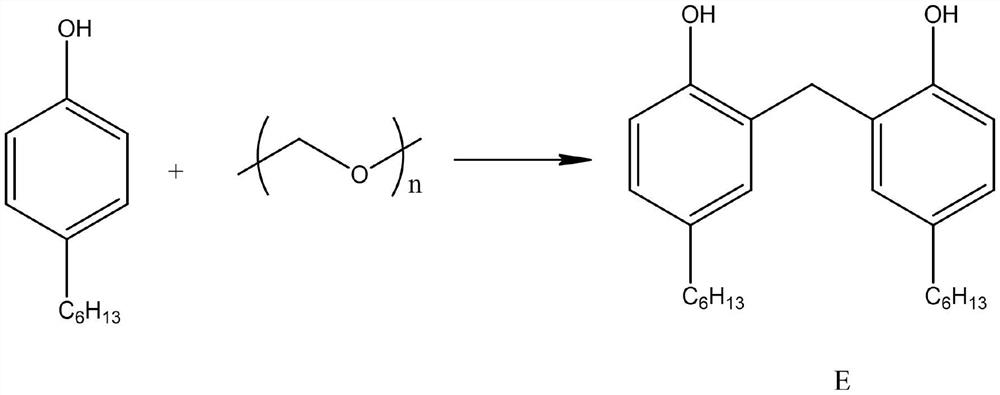

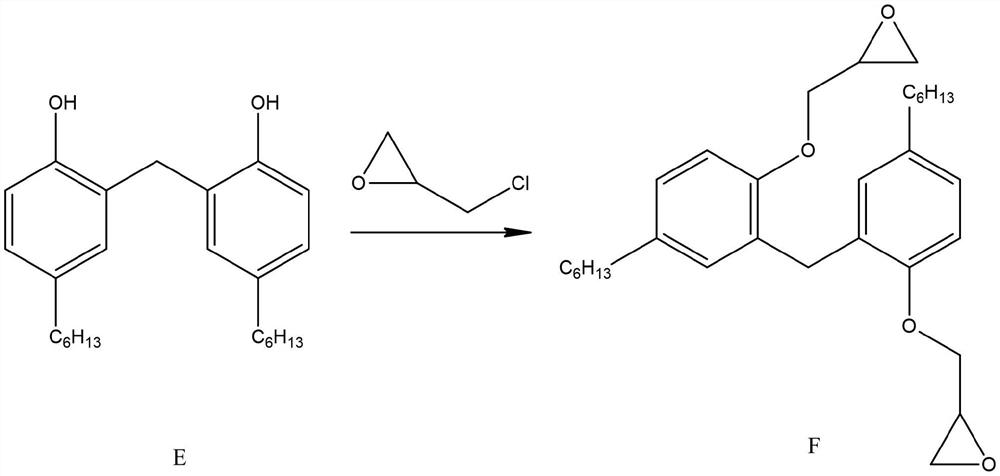

[0059] S11: adopt a vacuum distillation device, 4-hexylphenol is distilled, and the colorless transparent fractio...

Embodiment 2

[0072] The difference between this embodiment and Embodiment 1 is:

[0073] The finishing agent includes the following components in parts by weight:

[0074] 0.4 part of coupling agent, 1 part of emulsifier, 1 part of antistatic agent, 0.6 part of softener, and 97 parts of non-ionic water;

[0075] The emulsifier is prepared by the following steps:

[0076] S11: adopt a vacuum distillation device, 4-hexylphenol is distilled, and the colorless transparent fraction distilled is collected for subsequent use;

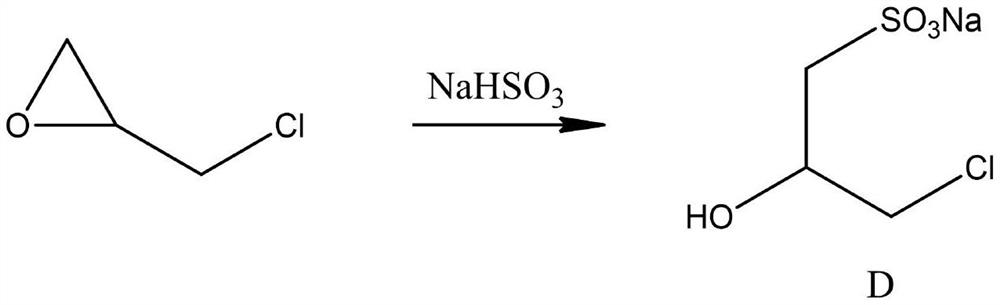

[0077] S12: put 20g of Na 2 SO 3 and 13g of NaHSO 3 Dissolved in distilled water and placed in a reaction four-necked flask equipped with an electric stirring device, a thermometer and a condensing device, at a temperature of 40 ° C, add 9 g of epichlorohydrin dropwise, and control the rate of addition to be 2 drops / s. After the addition, it was cooled with an ice-water bath and continued to react for 4 h, filtered under reduced pressure, and dried in vacuo to obtain ...

Embodiment 3

[0089] The difference between this embodiment and Embodiment 1 is:

[0090]The finishing agent includes the following components in parts by weight:

[0091] 0.2 part of coupling agent, 1.5 part of emulsifier, 1 part of antistatic agent, 0.4 part of softener, 96.9 parts of non-ionic water;

[0092] The emulsifier is prepared by the following steps:

[0093] S11: adopt a vacuum distillation device, 4-hexylphenol is distilled, and the colorless transparent fraction distilled is collected for subsequent use;

[0094] S12: put 20g of Na 2 SO 3 and 13g of NaHSO 3 Dissolved in distilled water and placed in a reaction four-necked flask equipped with an electric stirring device, a thermometer and a condensing device, at a temperature of 30 ° C, add 9 g of epichlorohydrin dropwise, and control the rate of addition to be 1 drop / s. After the addition, it was cooled with an ice-water bath and continued to react for 4 h, filtered under reduced pressure, and dried in vacuo to obtain In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com