Coal bed gas clean-fracturing fluid

A clean fracturing fluid and coalbed methane technology, applied in the field of coalbed gas fracturing, can solve the problems of high cost and wide application constraints, and achieve the effects of low cost, enhanced hydrophobic binding force, and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

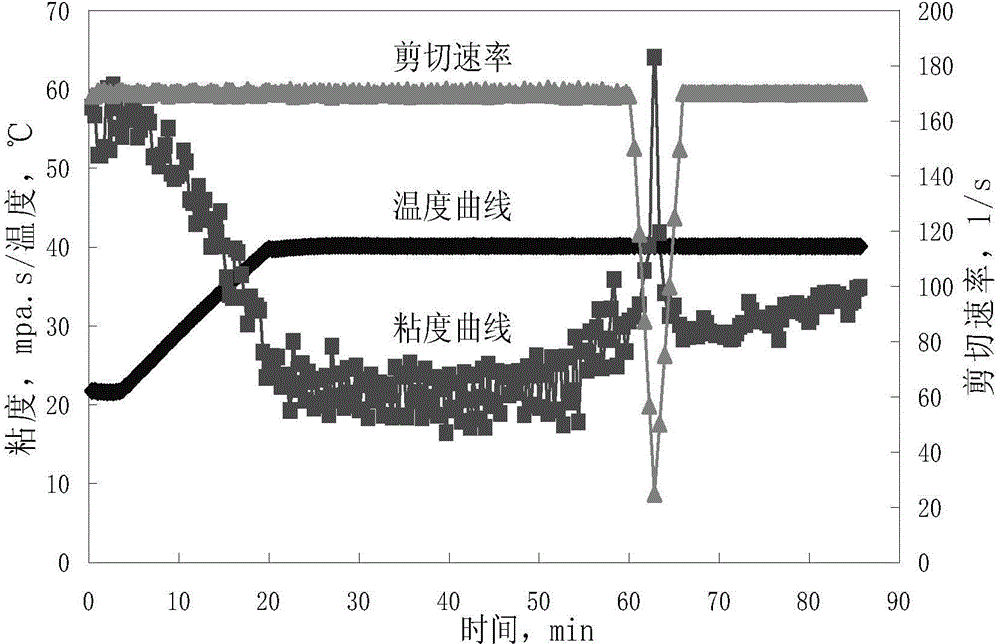

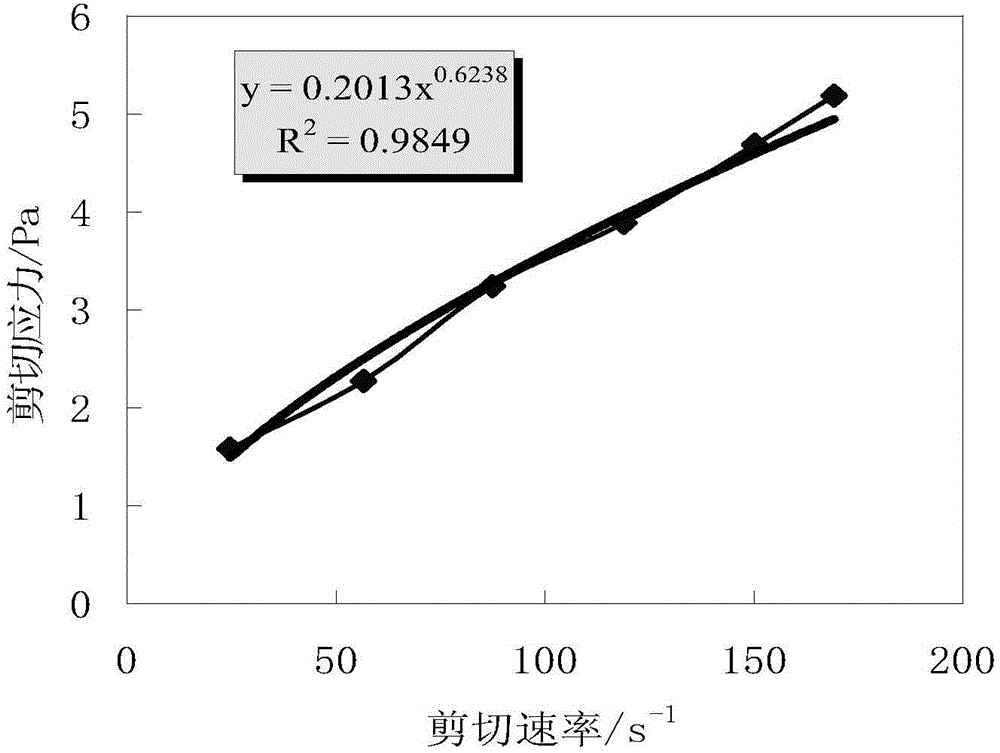

Examples

Embodiment 1

[0032] The clean fracturing fluid for coalbed methane in this embodiment is made by mixing the following raw materials in mass percent: 0.5% of a gemini-type surfactant with general formula III, 3% of a counter ion additive, and the balance is water; The counter ion additive is sodium salicylate;

[0033] The gemini-type surfactant having the general formula III is prepared by reacting a tertiary amine having the general formula I and a p-xylene substituent having the general formula II, and the reaction equation is:

[0034]

[0035] where R is C 12 h 25 ; X is Cl;

[0036] The preparation method of the gemini surfactant with general formula III comprises the following steps:

[0037] Step 1, reflux reaction: Add 0.2 mol of tertiary amine with general formula I and 0.1 mol of p-xylene substitute with general formula II into 20 mL of ethanol (chemical or analytical pure), and reflux at a temperature of 85°C Reacted for 48h, then distilled to obtain crude product;

[00...

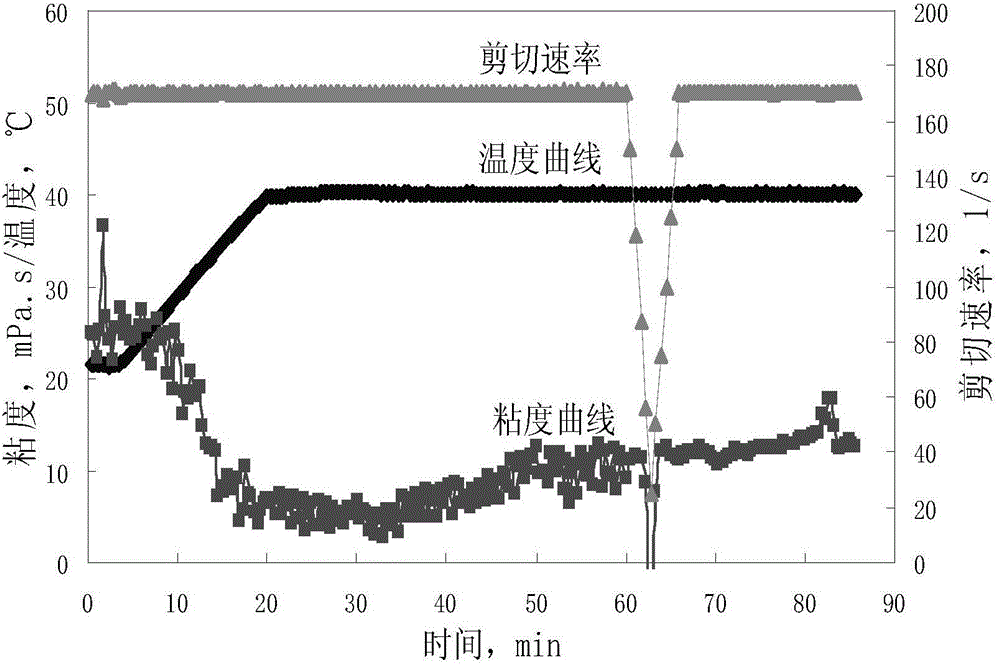

Embodiment 2

[0052] The coalbed methane clean fracturing fluid of this embodiment is made by mixing the following raw materials in mass percentage: 0.5% of a gemini-type surfactant with general formula III, 2% of a counter ion additive, and the balance is water; The counter ion aid is sodium bromide;

[0053] The gemini-type surfactant having the general formula III is prepared by reacting a tertiary amine having the general formula I and a p-xylene substituent having the general formula II, and the reaction equation is:

[0054]

[0055] where R is C 12 h 25 ;X is Br;

[0056] The preparation method of the gemini surfactant with general formula III comprises the following steps:

[0057] Step 1, reflux reaction: add 0.22mol of tertiary amine with general formula I and 0.1mol of p-xylene substitute with general formula II into 35mL of ethanol (chemical or analytical pure), and reflux at a temperature of 85°C Reacted for 48h, then distilled to obtain crude product;

[0058] Step 2, ...

Embodiment 3

[0063] The coalbed methane clean fracturing fluid of this embodiment is made by mixing the following raw materials in mass percentage: 3% of gemini surfactant with general formula III, 6% of counter ion additive, and the balance is water; The counter ion aid is potassium bromide;

[0064] The gemini-type surfactant having the general formula III is prepared by reacting a tertiary amine having the general formula I and a p-xylene substituent having the general formula II, and the reaction equation is:

[0065]

[0066] where R is C 14 h 29 ; X is Cl;

[0067] The preparation method of the gemini surfactant with general formula III comprises the following steps:

[0068] Step 1, reflux reaction: add 0.24mol of tertiary amine with general formula I and 0.1mol of p-xylene substitute with general formula II into 50mL of ethanol (chemical or analytical pure), and reflux at a temperature of 95°C Reacted for 24h, then distilled to obtain crude product;

[0069] Step 2, recryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com