Water-resistant oil-dispersion-resistant rosin size and preparation method thereof

A water-repellent, oil-repellent, rosin glue technology, applied in the direction of rosin addition, water-repellent agent addition, non-polymer organic compound addition, etc., can solve the problems of oil resistance and unsatisfactory dispersion, and achieve easy aggregation to form micelles, Effect of lowering surface tension and high water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

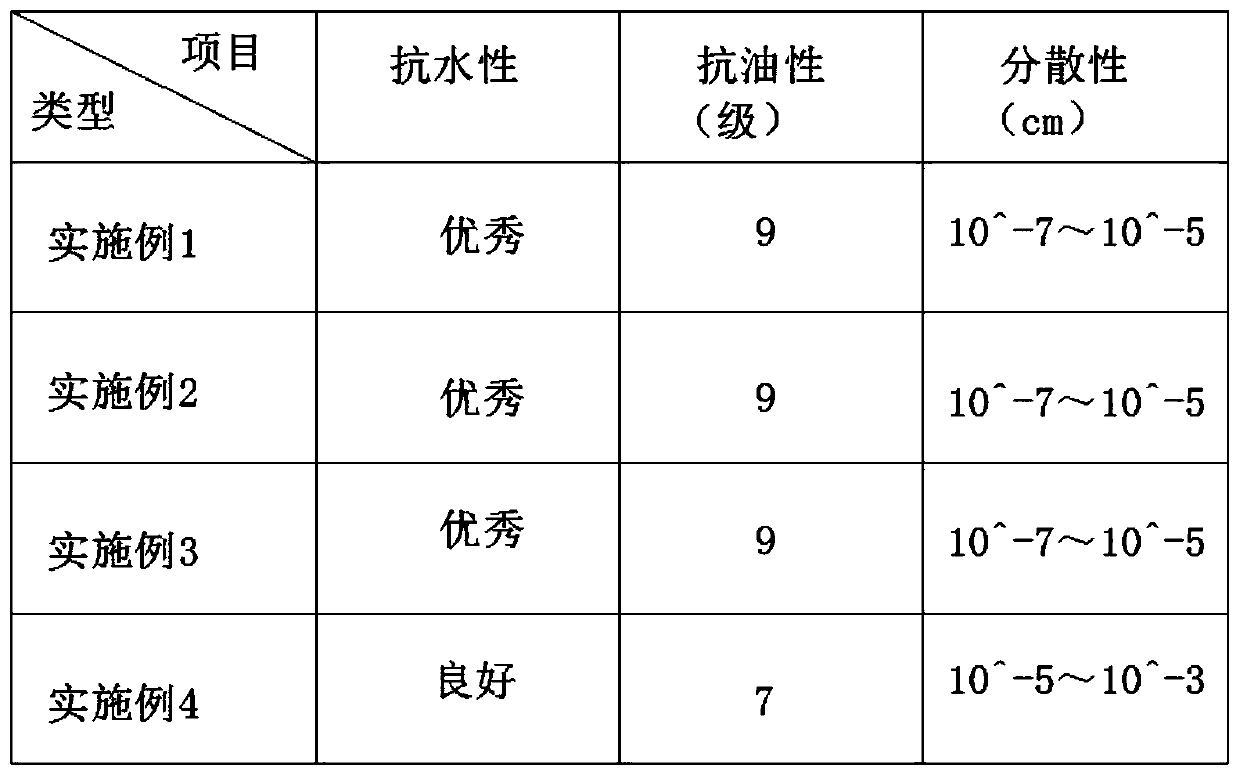

Examples

Embodiment 1

[0028] A water-resistant and oil-resistant disperse rosin gum and its preparation method, comprising the following composition percentages: 50% rosin gum, 30% rosin maleic anhydride polyol ester, 20% rosin, 20% acid anhydride, 9% oligomeric surfactant, 8- 12% fortified rosin gum, 8% petroleum wax, 10% tall oil, 8% oxidized polyethylene wax, 6% emulsifier, 15% tricyclic diterpenoid oxygenate, 10% polyacrylamide dispersant, 1% Catalyst, 20% polyethylene glycol, 30% alkylene oxide, 10% antioxidant and 6% esterification agent, its preparation method specifically comprises the following steps:

[0029] Step 1: Take the quality of rosin maleic anhydride polyol ester as a benchmark, add to No. 1 thermocouple reactor and heat and melt, add catalyst, Polyethylene Glycol, alkylene oxide in the molten rosin maleic anhydride polyol ester, in React at a temperature of 300-340°C for 1-2 hours;

[0030] Step 2: Carry out decompression and vacuum treatment on the No. 1 thermocouple reactor in ...

Embodiment 2

[0043] A water-resistant and oil-resistant disperse rosin gum and its preparation method, comprising the following composition percentages: 60% rosin gum, 40% rosin maleic anhydride polyol ester, 30% rosin, 30% acid anhydride, 13% oligomeric surfactant, 12% Fortified rosin gum, 10% petroleum wax, 12% tall oil, 10% oxidized polyethylene wax, 8% emulsifier, 25% tricyclic diterpenoid oxygenate, 14% polyacrylamide dispersant, 2% catalyst, 30% polyethylene glycol, 40% alkylene oxide, 12% antioxidant and 9% esterifying agent, its preparation method specifically comprises the following steps:

[0044] Step 1: Take the quality of rosin maleic anhydride polyol ester as a benchmark, add to No. 1 thermocouple reactor and heat and melt, add catalyst, Polyethylene Glycol, alkylene oxide in the molten rosin maleic anhydride polyol ester, in React at a temperature of 300-340°C for 1-2 hours;

[0045] Step 2: Carry out decompression and vacuum treatment on the No. 1 thermocouple reactor in s...

Embodiment 3

[0058] A water-resistant and oil-resistant disperse rosin gum and its preparation method, comprising 55% rosin gum, 35% rosin maleic anhydride polyol ester, 25% rosin, 25% acid anhydride, 11% oligomeric surfactant, 10% Strengthened rosin gum, 9% petroleum wax, 11% tall oil, 9% oxidized polyethylene wax, 7% emulsifier, 20% tricyclic diterpenoid oxygenate, 12% polyacrylamide dispersant, 1.5% catalyst, 25% polyethylene glycol, 35% alkylene oxide, 11% antioxidant and 7.5% esterifying agent, its preparation method specifically comprises the following steps:

[0059] Step 1: Take the quality of rosin maleic anhydride polyol ester as a benchmark, add to No. 1 thermocouple reactor and heat and melt, add catalyst, Polyethylene Glycol, alkylene oxide in the molten rosin maleic anhydride polyol ester, in React at a temperature of 300-340°C for 1-2 hours;

[0060] Step 2: Carry out decompression and vacuum treatment on the No. 1 thermocouple reactor in step 1, and keep the vacuum degree ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com