Degradable water clarifier for polymer flooding produced water and preparation method thereof

A technology for clear water agent and water use, which is applied in the petroleum industry and can solve the problems of intractable sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

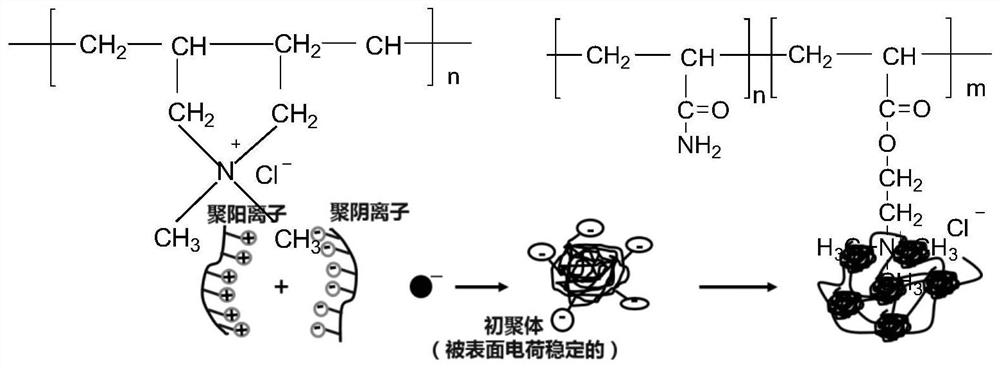

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1, the preparation of degradable water clearing agent

[0044] First, weigh 57g of N,N-dimethylacrylamide, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of initiator azobisisobutyl Nitrile reaction 8h, obtain N,N-dimethylacrylamide and diallylamine oligomer ethanol solution; Then, add 1.24g polyethylene glycol diacrylate (average molecular weight is 400mol / g, and its molar number is the same as The molar ratio of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained after reaction for 2 h; finally, 15.9 g of anhydrous formic acid (the molar number of which is the same as that of the chain-extended oligomer The molar ratio of the tertiary amine groups in the compound is 0.6:1), and the degradable water purifying agent 1 is obtained after reacting at 70°C for 1 hour.

Embodiment 2

[0045] Embodiment 2, the preparation of degradable water clearing agent

[0046] First, weigh 57g of N-(3-dimethylaminopropyl)methacrylamide, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of nitrogen to trigger Agent tert-butyl hydroperoxide was reacted for 8h to obtain N-(3-dimethylaminopropyl) methacrylamide and diallylamine oligomer ethanol solution; then, add 1.24g polyethylene glycol diacrylate (The average molecular weight is 400 mol / g, and the ratio of the number of moles to the number of moles of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained by reacting for 2 hours; finally, add 9.25 Water formic acid (the molar ratio of the molar number to the tertiary amine group in the chain-extended oligomer is 0.6:1), reacted at 70°C for 1 hour to obtain the degradable water purifying agent 2.

Embodiment 3

[0047]Embodiment 3, the preparation of degradable water clearing agent

[0048] First, weigh 57g of dimethylaminoethyl methacrylate, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of initiator azobisisobutyl Nitrile reaction 8h, obtain N,N-dimethylacrylamide and diallylamine oligomer ethanol solution; Then, add 1.24g polyethylene glycol diacrylate (average molecular weight is 400mol / g, and its molar number is the same as The molar ratio of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained after reaction for 2 hours; finally, 10 g of anhydrous formic acid is added, and its molar number is the same as that of the chain-extended oligomer The molar ratio of the tertiary amine groups is 0.6:1, and the degradable water purifying agent 3 is obtained after reacting at 70°C for 1 hour.

[0049] The performance evaluation results of the water purifiers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com