Dental matrix auxiliary material and preparation method thereof

A technology of matrix and excipients, applied in the field of oral care, can solve the problems of inability to continuously exert the drug effect, exposure of the active part, poor treatment effect, etc., and achieve the effects of controlling bacterial growth, ensuring long-term retention, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

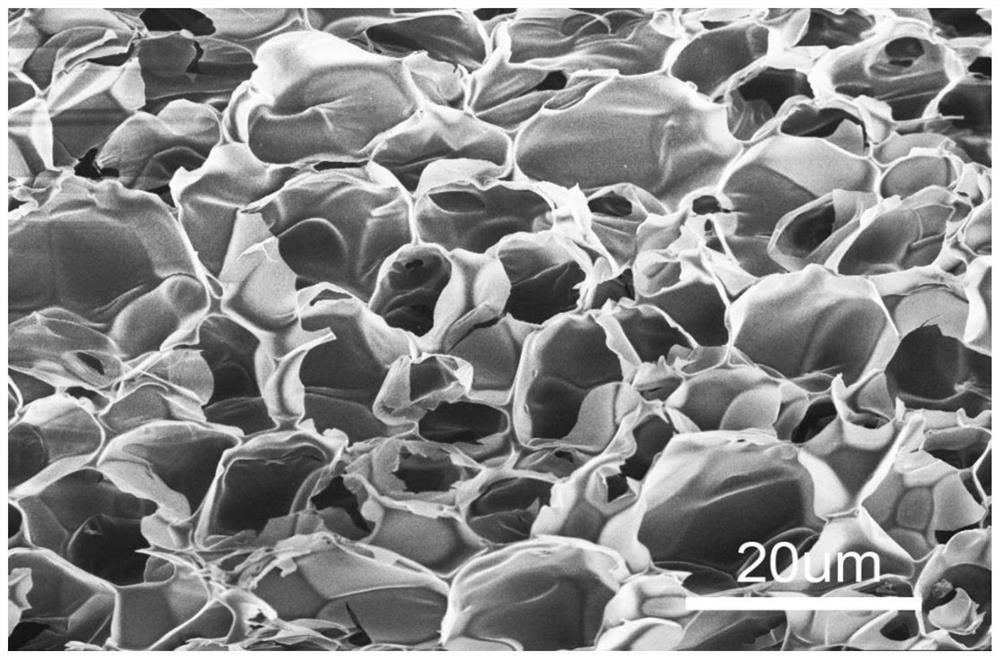

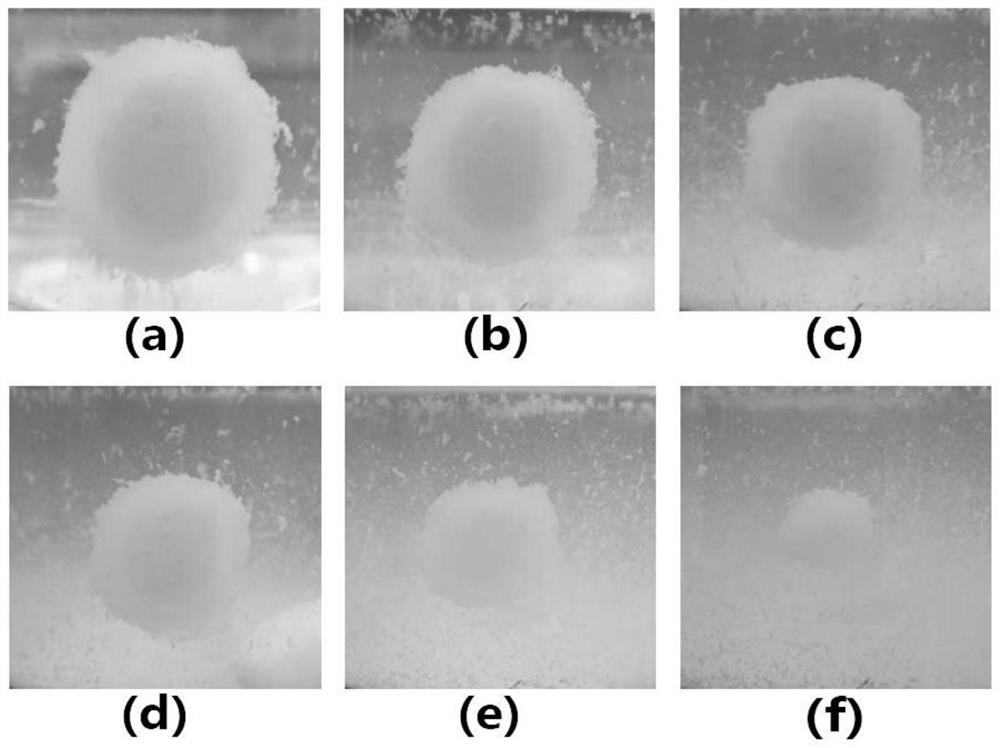

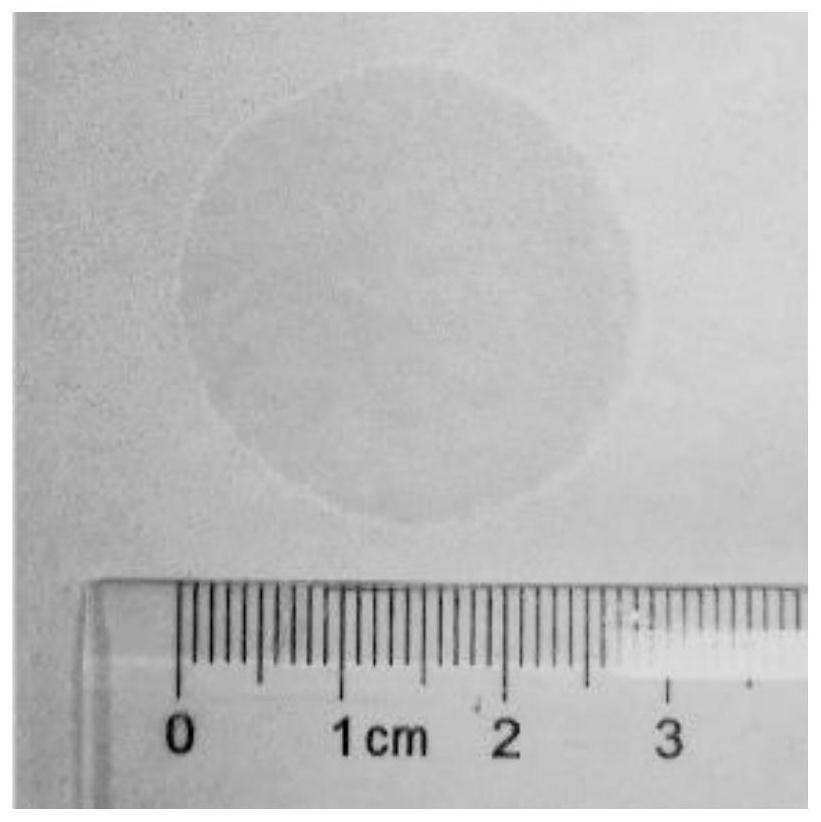

Image

Examples

preparation example Construction

[0069] The present invention further gives a method of preparing a dental matrix excipient, including the following steps.

[0070] Step 1, according to the proportional hydrophobic polymer, the powder material is 40 mesh sieve;

[0071] As one of the optional embodiments, the solid material is pulverized using a pulverizer, a 40 mesh screen;

[0072] Step 2, a hydrophobic polymer is placed in a stirring apparatus, and the mixture is added to the stirring apparatus, and the stirring is added to 200-250 rpm (revolution per minute), and the mixing solution A is obtained.

[0073] Alternatively, the hydrophobic polymer is placed in a laboratory kneading machine, which is adjacent to the diluent and a plasticizer, and the laboratory kneading machine is sealed, and the laboratory kneading machine is sealed and closed, at 160-165 ° C, 180-200 rpm Melting, kneading 3H, cooling, obtained a mixture A;

[0074] Step 3, according to the ratio of hydrophilic polymer, add a uniform solution A,...

Embodiment 3

[0085] Example 3 Preparation method of dental matrix excipient, in step 2, a laboratory kneading machine is selected; in step 2, the diluent is adjacent to the liquid paraffin, and the plasticizer is adjacent to the polyethylene wax, and Brazilian palm wax; Fusion, kneading, cooling under 160 ° C, 200 rpm; in step 3, the diluent is adjacent to 95% ethanol; stirring is continued at 50 ° C in a closed condition. Specific steps are as follows:

[0086] Step 1, according to the proportional hydrophobic polymer, the powder material is 40 mesh sieve;

[0087] Step 2, placing the hydrophobic polymer in the laboratory kneader, the diluent is adjacent to the liquid paraffin, the plasticizer is adjacent to the polyethylene wax, Brazilian palm wax, and the laboratory kneading machine is sealed, The melting is melted at 160 ° C, 200 rpm, kneading 3 h, cooled, and a mixture of mixture A is obtained;

[0088] Step 3, according to the ratio of hydrophilic polymer, the diluent is adjacent to 95% ...

Embodiment 4

[0091] Example 4 Preparation method of dental matrix excipient, in step 2, a laboratory kneading machine is selected; in step 2, the diluent is adjacent to liquid paraffin, and the plasticizer is adjacent to the solid paraffin; at 165 ° C, 180 rpm, melting, Kneaded, cooling; in step 3, the diluent is adjacent to glycerin, and the plasticizer is adjacent to the beeswax, phospholipid; at 60 ° C. Stir.

[0092] Specific steps are as follows:

[0093] Step 1, according to the proportional hydrophobic polymer, the powder material is 40 mesh sieve;

[0094] Step 2, placing the hydrophobic polymer in the laboratory kneader, the diluent is adjacent to liquid paraffin, and the plasticizer is adjacent to the laboratory kneading machine, and the laboratory kneading machine is closed, and the molten at 165 ° C, 180 rpm. Knead 3H, cool, resulting in a mixture A;

[0095] Step 3, according to the proportion to the peer-to-petrogen, the diluent is adjacent to glycerin, and the plasticizer is adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com