Application of degradable water clarifier

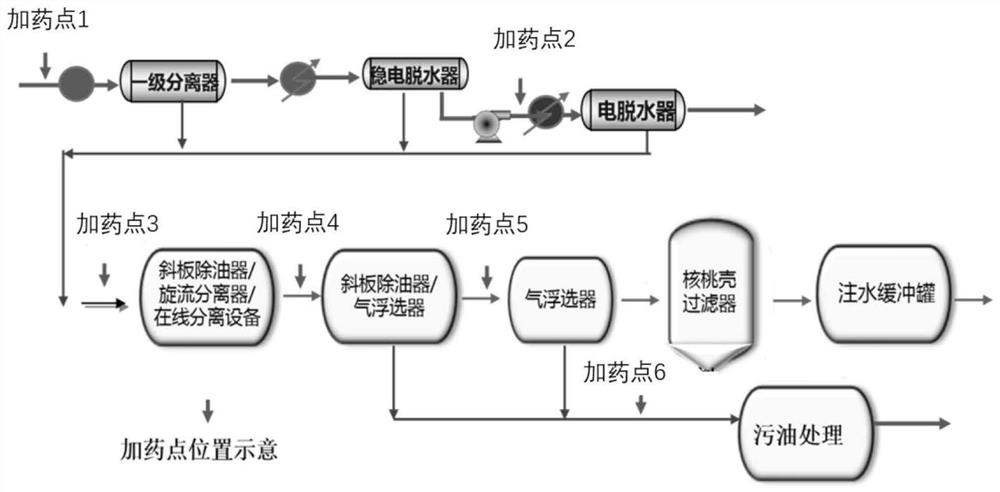

A technology of water clearing agent and medicament, applied in the field of degradable water clearing agent, which can solve the problems of reducing the effective utilization rate of equipment and pipelines, increasing power consumption, increasing liquid flow volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

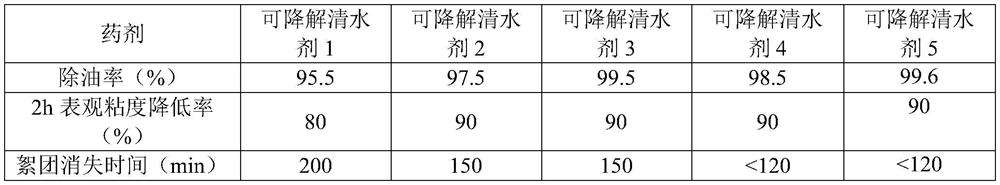

[0045] Embodiment 1, the preparation of degradable water clearing agent

[0046] First, weigh 57g of N,N-dimethylacrylamide, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of initiator azobisisobutyl Nitrile reaction 8h, obtain N,N-dimethylacrylamide and diallylamine oligomer ethanol solution; Then, add 1.24g polyethylene glycol diacrylate (average molecular weight is 400mol / g, and its molar number is the same as The molar ratio of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained after reaction for 2 h; finally, 15.9 g of anhydrous formic acid (the molar number of which is the same as that of the chain-extended oligomer The molar ratio of the tertiary amine groups in the compound is 0.6:1), and the degradable water purifying agent 1 is obtained after reacting at 70°C for 1 hour.

Embodiment 2

[0047] Embodiment 2, the preparation of degradable water clearing agent

[0048]First, weigh 57g of N-(3-dimethylaminopropyl)methacrylamide, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of nitrogen to trigger Agent tert-butyl hydroperoxide was reacted for 8h to obtain N-(3-dimethylaminopropyl) methacrylamide and diallylamine oligomer ethanol solution; then, add 1.24g polyethylene glycol diacrylate (The average molecular weight is 400 mol / g, and the ratio of the number of moles to the number of moles of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained by reacting for 2 hours; finally, add 9.25 Water formic acid (the molar ratio of the molar number to the tertiary amine group in the chain-extended oligomer is 0.6:1), reacted at 70°C for 1 hour to obtain the degradable water purifying agent 2.

Embodiment 3

[0049] Embodiment 3, the preparation of degradable water clearing agent

[0050] First, weigh 57g of dimethylaminoethyl methacrylate, 3g of diallylamine and 40g of ethanol into the reactor, raise the temperature to 55°C, and add 0.3g of initiator azobisisobutyl Nitrile reaction 8h, obtain N,N-dimethylacrylamide and diallylamine oligomer ethanol solution; Then, add 1.24g polyethylene glycol diacrylate (average molecular weight is 400mol / g, and its molar number is the same as The molar ratio of the secondary amino groups in the oligomer is 0.1:1), the temperature is raised to 70°C, and the chain-extended oligomer is obtained after reaction for 2 hours; finally, 10 g of anhydrous formic acid is added, and its molar number is the same as that of the chain-extended oligomer The molar ratio of the tertiary amine groups is 0.6:1, and the degradable water purifying agent 3 is obtained after reacting at 70°C for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com