Crayfish shell seasoning powder and processing method thereof

A processing method and technology of lobster shells, which are applied in the field of crayfish shell seasoning powder and its processing, can solve the problems of polluting the environment, low added value, discarding and wasting shrimp shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

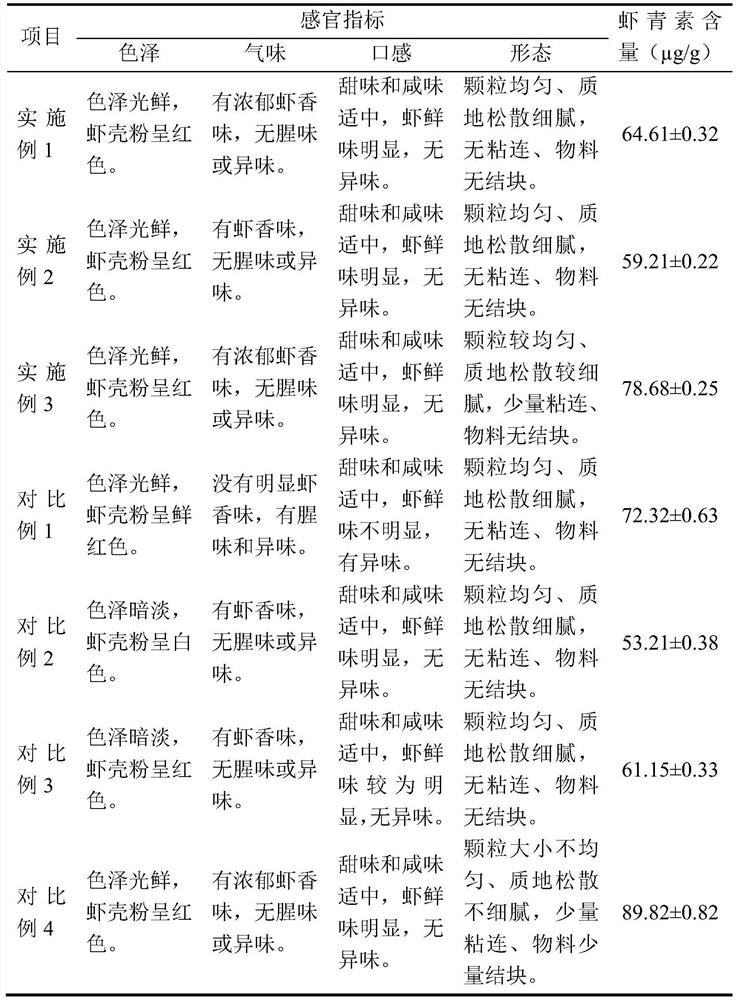

Examples

Embodiment 1

[0043] (1) select 100g bright red color and luster, without obvious corruption, damaged crayfish shells;

[0044] (2) Wash the selected crayfish shells with tap water, remove the shrimp feet and other sundries remaining in the shrimp shells with scissors, and soak in 2% citric acid solution for 10 minutes (the ratio of shrimp shells to solution is 1:2) , wash with tap water 3 times. Then put it into a solution of 2% salt (the ratio of shrimp shells to salt water is 1:10), boil for 5 minutes, drain and set aside;

[0045] (3) Place the crayfish shells in the step (2) in brine, the weight ratio of the crayfish shells to the brine is 1:10, cook under normal pressure to remove the fishy smell, and the time for removing the fishy smell is 40 minutes;

[0046] (4) Put the crayfish shells after deodorization in step (3) into a hot air drying oven for drying, the drying time is 60 minutes, and the drying temperature is 80° C.;

[0047] (5) Superfinely pulverizing the dried crayfish ...

Embodiment 2

[0051] The difference from Example 1 is that in step (4), the drying time is 70min.

Embodiment 3

[0053] The difference from Example 1 is that in step (5), the speed of the ultrafine pulverizer is 500 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com