Plant protein beverage containing sunflower seed pulp and making method thereof

A technology of vegetable protein beverage and sunflower seed, which is applied in the field of vegetable protein beverage and its preparation, can solve problems such as unfavorable health, difficult to remove chlorogenic acid, precipitation, etc., to ensure color and taste, improve hydration ability, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

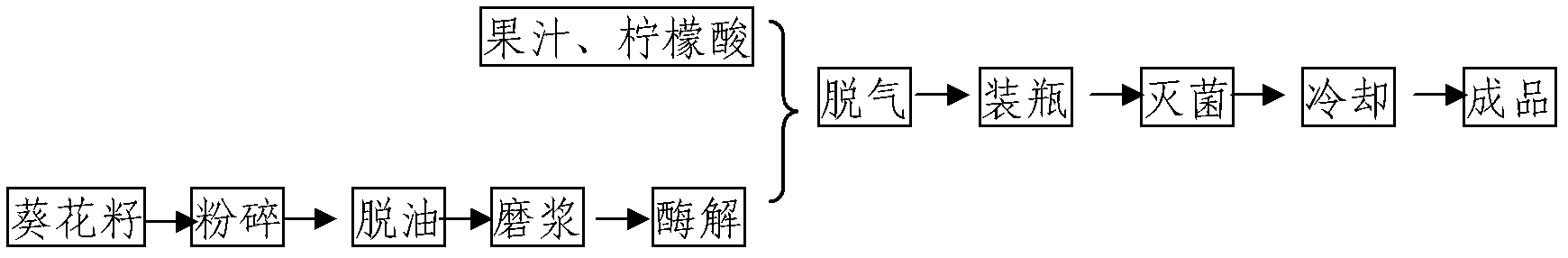

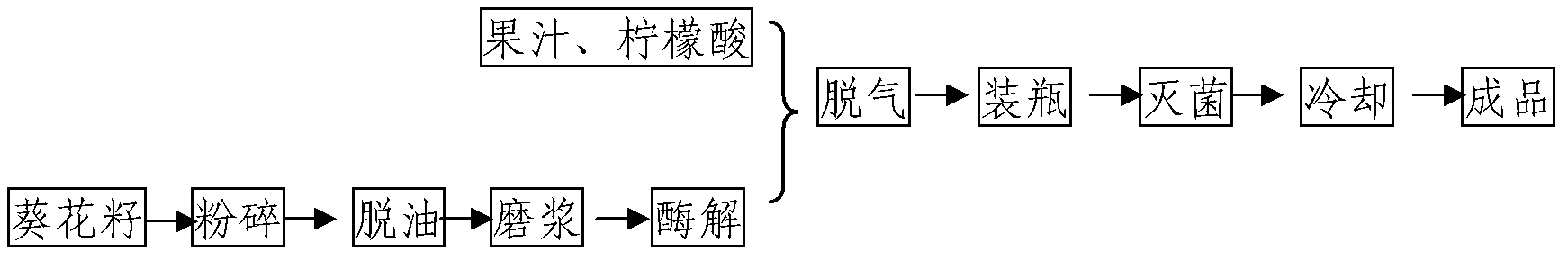

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of sunflower pulp

[0030] (1) Peeling and crushing of sunflower seeds: Weigh 50kg of peeled sunflower seeds and crush them into 12-mesh samples. After crushing, the particles smaller than 1.70mm in the sunflower seeds account for 70%; (2) Deoiling of sunflower seeds: set CO 2 The pressure of the separation tank I of the supercritical extraction machine is 7-8MPa, and the temperature is 60°C; the pressure of the separation tank II is 4-6MPa, and the temperature is 35°C. Put the crushed sunflower seeds into the extraction tank for extraction, set the extraction pressure to 35MPa, the extraction temperature to 35°C, CO 2 The flow rate is 25kg / h, and the extraction is 60min. The oil remaining in the sunflower seeds after extraction is the original 10% mass ratio; (3) add water and grind: take out the sunflower seeds that have been removed from the oil and place them in a stainless steel bucket, add 4 times the amount of peeled sunflower seeds Weight...

Embodiment 2

[0031] Embodiment 2: preparation contains the sunflower seed vegetable protein drink of hawthorn fruit juice

[0032] Take 50kg of fresh hawthorn, moderately crush it, put it into a stainless steel bucket, add 10 times of water, add liquid pectinase at 40°C and incubate for 6 hours, filter to remove residue, clarify at room temperature, and take the supernatant as fruit juice for production.

[0033] The sunflower pulp obtained in Example 1 was placed in a stainless steel tank with a stirrer, and then 10kg of hawthorn fruit juice was added to the sunflower pulp obtained in Example 1, stirred with a stirrer to make it fully mixed. Add 2 kg of sucrose and 0.2 kg of citric acid into the mixture to fully dissolve, adjust the pH value to about 4.0, perform secondary homogenization at a pressure of 40 MPa and a temperature of 40° C., and make a sunflower seed vegetable protein beverage. The sunflower seed vegetable protein beverage prepared above is heated to 80° C., enters a degass...

Embodiment 3

[0035] Example 3: Preparation of sunflower pulp

[0036] (1) Sunflower seeds are peeled and crushed: take 50 kg of peeled sunflower seeds and crush them into 12 mesh samples. After crushing, the particles less than 1.70 mm in the sunflower seeds account for 80%; The seeds are put into the extractor for extraction, the solvent used is n-hexane, the extraction temperature is set at 60° C., and the extraction time is 3 hours. After extraction, the oil remaining in the sunflower seeds is the original 12% (mass ratio); (3) Add water and grind Take out the sunflower seeds that remove grease and place in stainless steel barrel, add 5 times of weight water (250kg), water temperature 40 ℃, with beater material is pulverized, then cross colloid mill twice, make sunflower seed puree; (4 )Compound enzyme treatment: Put the sunflower seed puree into a stainless steel double-layer pot, add 50g of protease and 25g of cellulase for enzymolysis, the enzymolysis temperature is 40°C, the enzymol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com