Synthesis system and method for preparing adiponitrile by ammoniation of adipic acid

A technology of adipic acid and adiponitrile, which is applied in the field of synthesis system of adipic acid ammonification to prepare adiponitrile, which can solve the problem of difficult breakthrough in reaction performance, low efficiency of reaction separation system and long reaction residence time and other problems to achieve the effect of improving the yield of adiponitrile and selectivity, improving the mass transfer effect, and improving the reaction and separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

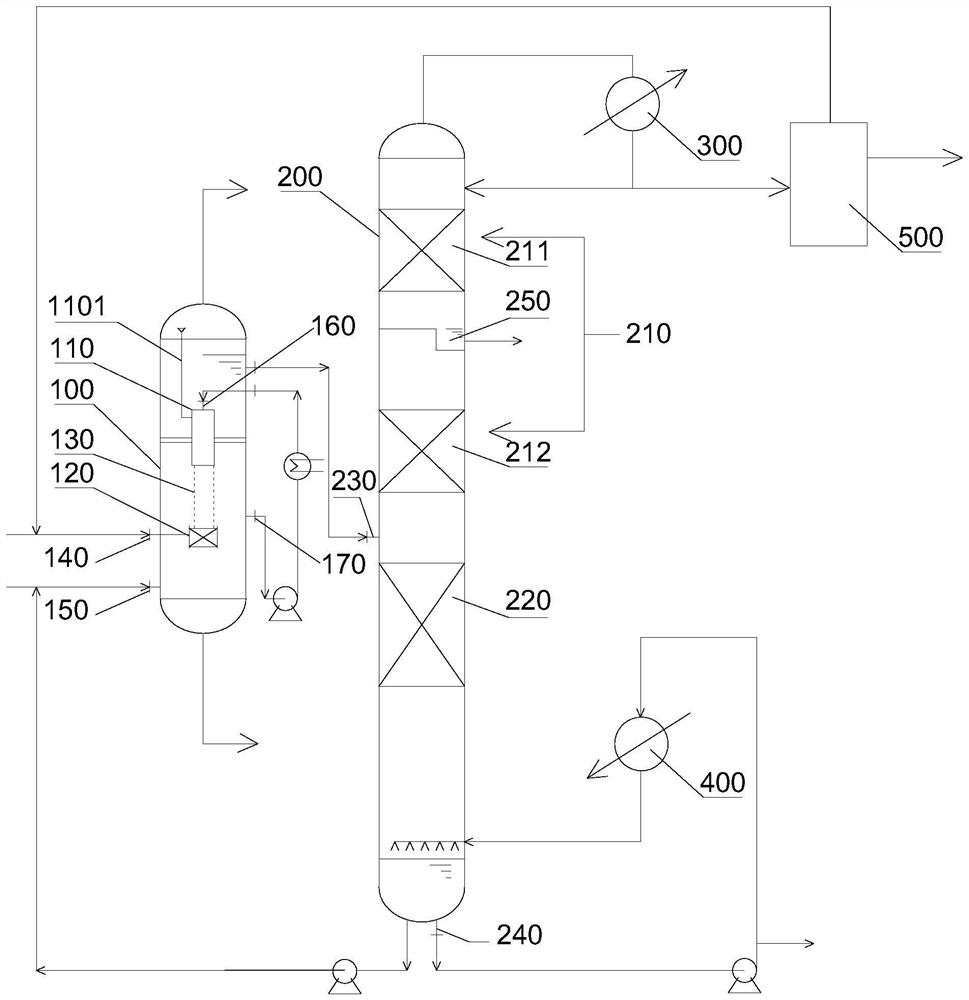

[0069] refer to figure 1 As shown, it is a synthetic system for preparing adiponitrile through ammoniation of adipic acid according to an embodiment of the present invention, which includes two major equipment bodies, an ammoniation reactor 100 and a reactive distillation column 200 connected in sequence.

[0070] Wherein, the ammoniation reactor 100 is provided with a raw material inlet and a reaction liquid outlet 170 , and the raw material inlet includes an ammonia gas inlet 140 and adipic acid inlet 150 .

[0071] The ammoniation reactor 100 is provided with a micro-interface generating system for dispersing ammonia gas and / or reaction feed liquid. The micro-interface generating system is mainly composed of a first micro-interface generator 110 and a second micro-interface generator 120 which are arranged up and down.

[0072] The first micro-interface generator 110 and the second micro-interface generator 120 are fixed inside the ammoniation reactor 100, and the first mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com