Treatment device and process for edge of glass of kitchen appliance

A glass edge and processing technology, applied in glass production and other directions, can solve the problems of broken glass strength, strength reduction, glass damage, etc., and achieve the effect of enhancing safety in use and restoring strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

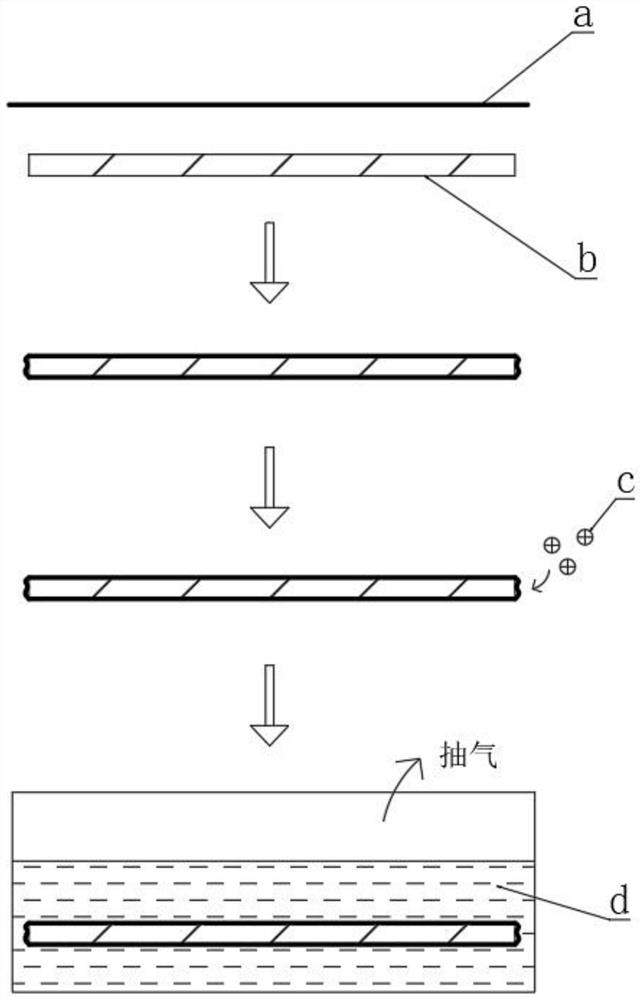

[0046] see figure 1 , a kitchen appliance glass edge treatment process, comprising the following steps:

[0047] S1, cleaning and drying the glass to be treated (indicated by a in the figure) to remove surface dust and impurities;

[0048] S2, prepare a waterproof cloth (represented by b among the figure), carry out lubricating pretreatment;

[0049] S3. Wrap the pretreated waterproof cloth on the outer surface of the glass evenly, subtract the excess area, and perform semi-open fixing operation on the waterproof cloth and the glass;

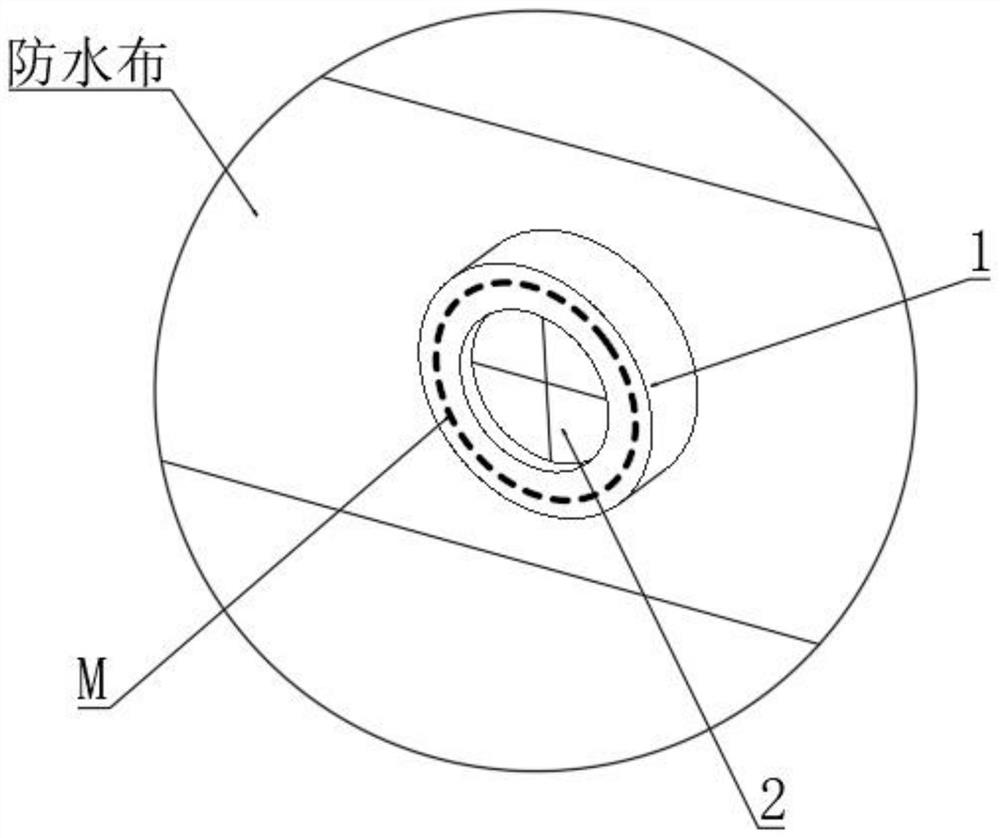

[0050] S4. A plurality of through holes are evenly prepared at the side ends of the waterproof cloth, and a petal-shaped semi-open sealing ring (indicated by c in the figure) is fixedly connected to the outer ends of the through holes to seal the through holes;

[0051] S5. Soak the tarpaulin and glass in a container filled with repair fluid (indicated by d in the figure). In a sealed environment, extract the air in the container so that the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com