Oil well cement high-temperature strength stabilizer and cement paste for well cementation, and preparation method of cement paste

A high-temperature strength and oil well cement technology, which is applied in the field of oil well cement admixtures for oil and gas well cementing operations, can solve the problems that it is difficult to ensure the development of long-term compressive strength, the long-term strength decline of cement stones, and cannot be effectively solved, so as to achieve guarantee Long-term sealing integrity, improving compactness, and overcoming the effect of not stabilizing existence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Another aspect of the present invention provides a kind of preparation method of well cementing cement slurry, and described preparation method comprises the following steps:

[0028] Dry mix the above oil well cement high temperature strength stabilizer, suspension stabilizer, iron ore powder, dispersant and portland cement according to the mass ratio of 60~80:4~5.3:0~92.1:0~2.1:100, to obtain a solid mixture;

[0029] Subsequently, the fluid loss additive, retarder, and defoamer are added to water and mixed evenly to obtain a slurry mixture, wherein the fluid loss additive, retarder, defoamer, and water account for the Portland cement The mass percentages are 7.4% to 10.8%, 6.4% to 10.5%, 0.32% to 0.53% and 52.5% to 60%, respectively;

[0030]Finally, the solid mixture is mixed with the slurry mixture to obtain cement slurry for well cementing.

[0031] For example, the oil well cement high-temperature strength stabilizer, suspension stabilizer, iron ore powder, dis...

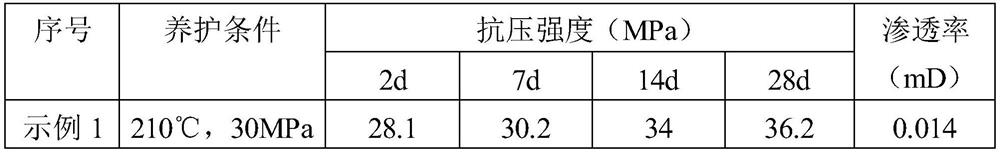

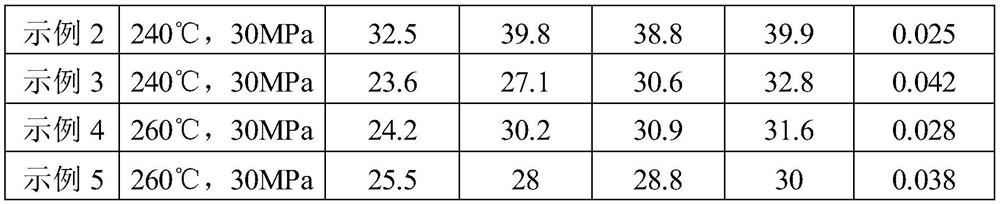

example 1

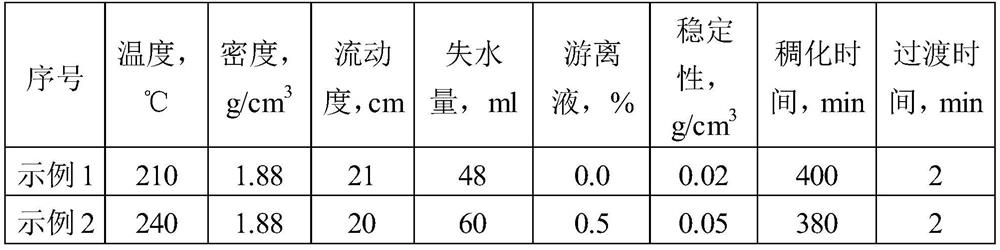

[0035] In this example, weigh 500g of grade G oil well cement, 300g of high temperature strength stabilizer, 20g of suspension temperature agent, 32g of fluid loss control agent, 24g of retarder, 1.6g of defoamer, and 262.4g of tap water. First dry mix the high temperature strength stabilizer, suspension stabilizer and cement evenly, then add the fluid loss reducer, retarder and defoamer into tap water and mix evenly, finally put the liquid material into the mixing cup, start the motor and keep Rotate at 4000r / min±200r / min, then add dry-mixed materials, cover the lid of the mixing cup after all the addition, and continue to stir at 12000r / min±500r / min for 35s to prepare cement slurry.

example 2

[0037] In this example, weigh 470g G grade oil well cement, 330g high temperature strength stabilizer, 20g suspension stabilizer, 32g fluid loss control agent, 24g retarder, 1.6g defoamer, and 262.4g tap water. First dry mix the high temperature strength stabilizer, suspension stabilizer and cement evenly, then add the fluid loss reducer, retarder and defoamer into tap water and mix evenly, finally put the liquid material into the mixing cup, start the motor and keep Rotate at 4000r / min±200r / min, then add dry-mixed materials, cover the lid of the mixing cup after all the addition, and continue to stir at 12000r / min±500r / min for 35s to prepare cement slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com