Dry-mixed mortar and preparation method thereof

A dry-mixed mortar and quartz sand technology, which is applied in clay preparation equipment, chemical instruments and methods, cement mixing equipment, etc., can solve the problems of poor water retention effect of dry-mixed mortar, flying dust of raw materials, poor crack resistance, etc., and achieve water retention Strong effect, good crack resistance, fast discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of dry-mixed mortar, the preparation of described dry-mixed mortar comprises the following steps:

[0026] Step 1: Add ordinary Portland cement, fly ash, diabase powder, quartz sand, ilmenite powder, sepiolite powder and citric acid slag powder to the three-pass dryer for drying treatment, and then add dry powder Stir evenly in a mixer;

[0027] Step 2: Add chopped carbon fiber and polymer to the mixture in Step 1, and stir evenly;

[0028] Step 3: Add etherified starch, thickening powder and polycarboxylate superplasticizer into a V-type high-efficiency mixer, and stir evenly;

[0029] Step 4: Add the mixture in step 3 to the mixture in step 2, stir evenly, measure and pack.

[0030] The present invention is one step closer, and the parts by weight of ordinary Portland cement, fly ash, diabase powder, quartz sand, ilmenite ore powder, sepiolite powder and citric acid slag powder in said step 1 are respectively : 95 parts of ordinary port...

Embodiment

[0038] Step 1: Take 95 parts of ordinary Portland cement, 45 parts of fly ash, 8 parts of diabase powder, 780 parts of quartz sand, 5 parts of ilmenite ore powder, 6 parts of sepiolite powder and 12 parts of citric acid slag powder, Add it to the three-pass dryer for drying treatment, and then add it to the dry powder mixer for uniform mixing. Step 2: Add 3 parts of chopped carbon fiber and 20 parts of polymer to the mixture in Step 1, and stir evenly. Step 3: Add 0.5 parts of etherified starch, 5 parts of thickening powder, and 1.2 parts of polycarboxylate superplasticizer into a V-type high-efficiency mixer, and stir evenly. Step 4: Add the mixture between step 3 to the mixture in step 2 , stir evenly, measure and pack;

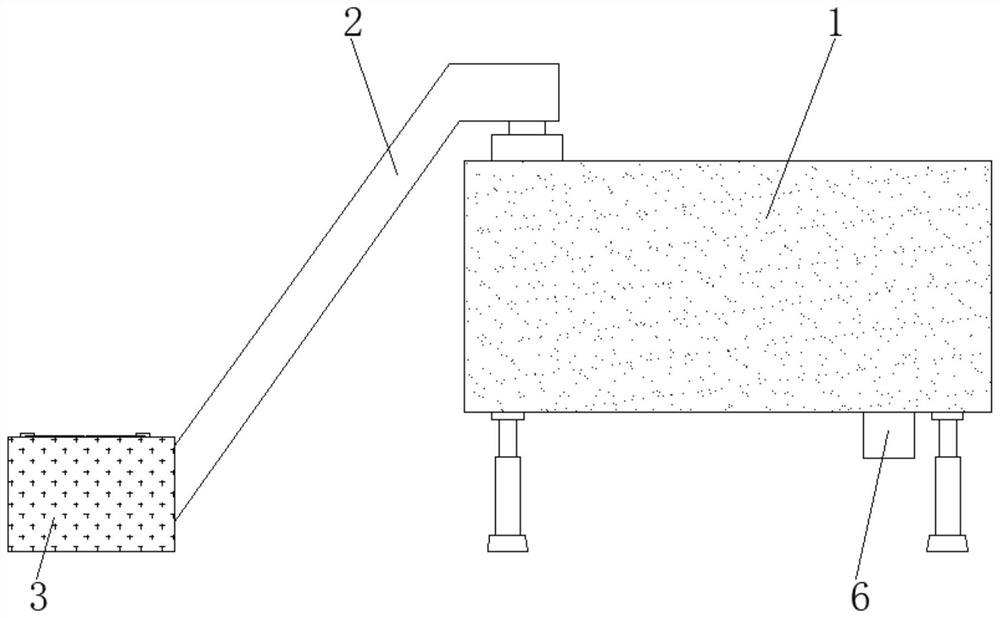

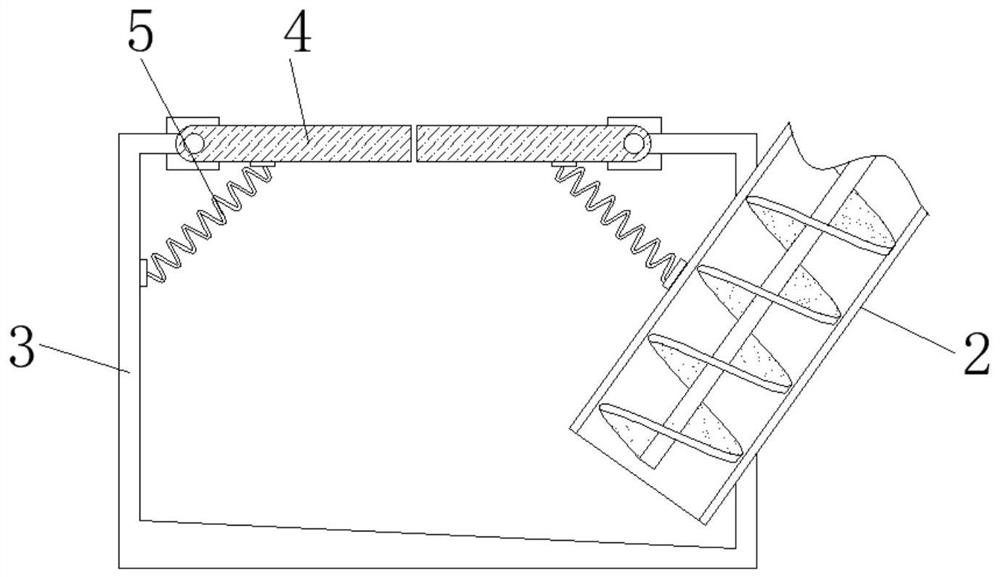

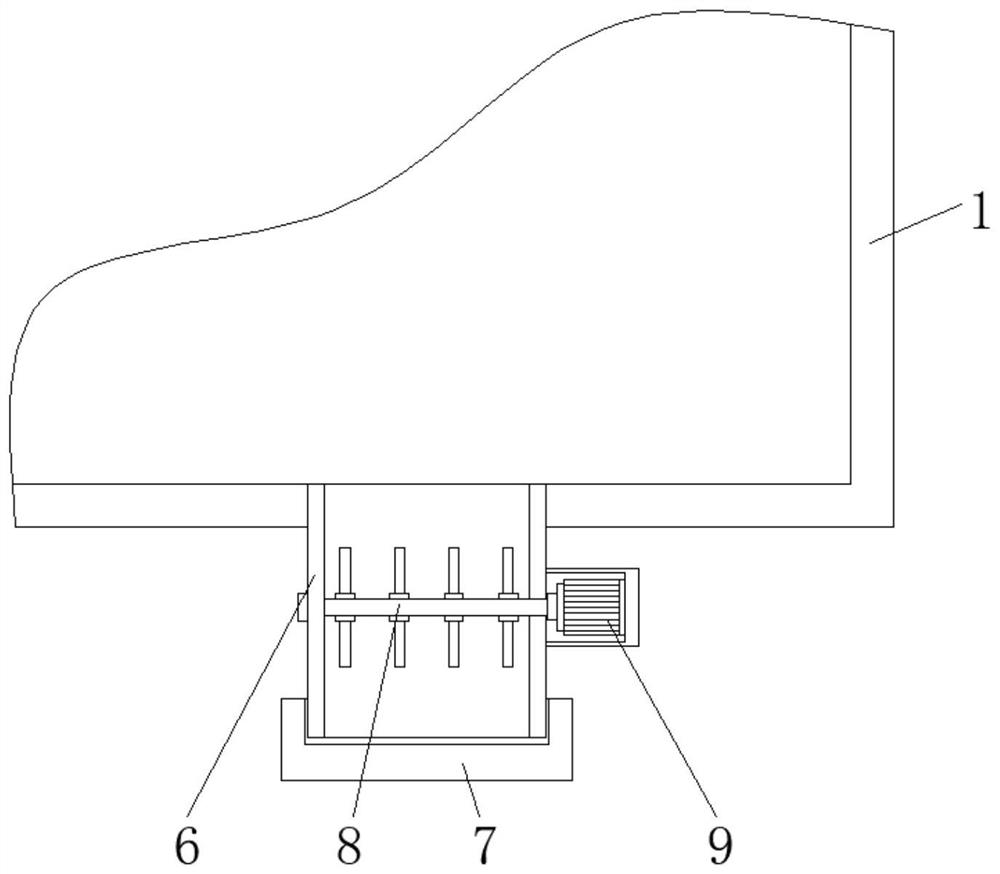

[0039] Among them, when ordinary Portland cement, fly ash, diabase powder, quartz sand, ilmenite powder, sepiolite powder and citric acid slag powder are uniformly mixed through a dry powder mixer, the materials are first put into the feeding In the box 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com