Polylactic acid composite material with high melt fluidity and preparation method thereof

A polylactic acid material and polylactic acid technology are applied in the field of high melt fluidity polylactic acid composite materials and their preparation, which can solve the problems of little research on flow aids, improve tensile strength and comprehensive performance, promote reduction, decrease The effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

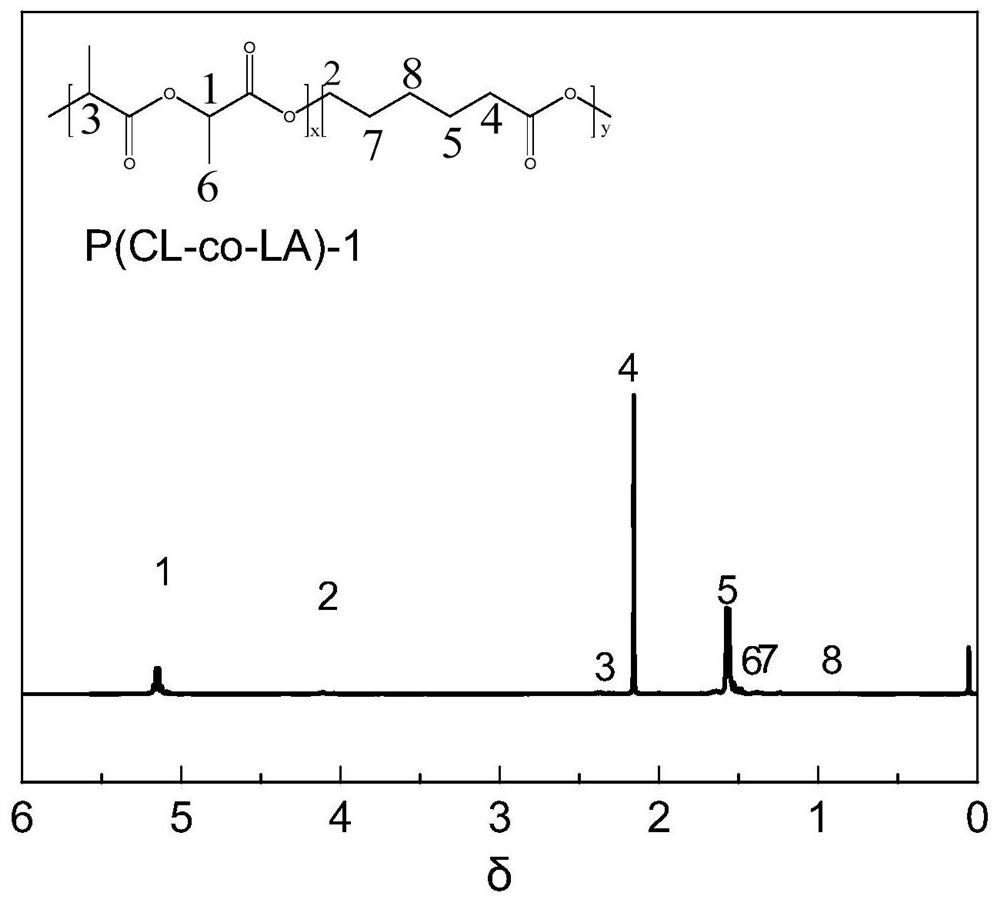

[0040] The preparation of embodiment 2 flow aid P (CL-co-LA) linear random copolymer

[0041] Add 25g dehydrated lactide, 6.89gε-caprolactone, 0.04g stannous isooctanoate, 0.17g propylene glycol to a 100ml three-necked flask, vacuum and reduce pressure, heat up and react for 24 hours to obtain a solid component, dissolve in trichloro Methane and methanol were precipitated to obtain a solid sample which was designated as P(CL-co-LA)-2.

Embodiment 3

[0042] The preparation of embodiment 3 flow aid P (CL-co-LA) linear random copolymer

[0043] Add 25g of dehydrated lactide, 17.8g of ε-caprolactone, 0.04g of stannous isooctanoate, 0.21g of ethanol to a 100ml three-necked flask, vacuum and reduce pressure, heat up and react for 24 hours to obtain a solid component, which is dissolved in trichloro Methane and methanol were precipitated to obtain a solid sample which was designated as P(CL-co-LA)-3.

Embodiment 4

[0044] The preparation of embodiment 4 flow aid P (CL-co-LA) linear random copolymer

[0045] Add 25g of dehydrated lactide, 52.6g of ε-caprolactone, 0.08g of stannous isooctanoate, 0.25g of propylene glycol into a 100ml three-necked flask, vacuum and reduce pressure, heat up and react for 24 hours to obtain a solid component, dissolve in trichloro Methane and methanol were precipitated to obtain a solid sample which was designated as P(CL-co-LA)-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com