Tackifying spinning process for regeneration of waste polyester

A polyester and waste technology, which is applied in the field of tackifying spinning technology for recycling waste polyester, can solve the problems of poor antibacterial performance of polyester products, failure of regeneration and tackifying, affecting service life, etc., and achieve stable product quality, improved antibacterial performance, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

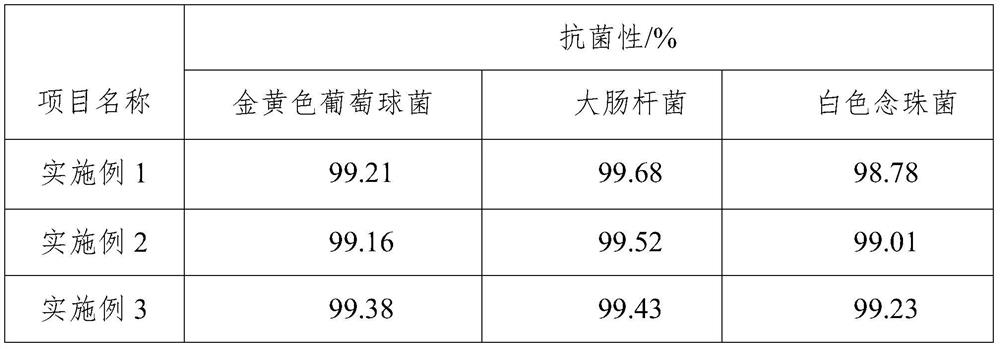

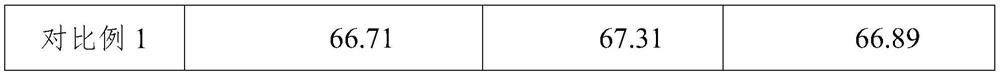

Examples

Embodiment 1

[0028] A kind of viscosity-increasing spinning process for regeneration of waste polyester in this embodiment comprises the following preparation steps:

[0029] A viscosifying spinning process for recycling waste polyester, comprising the following preparation steps:

[0030] S1. Soak the waste polyester products after cleaning and drying in benzalkonium bromide solution for 5 minutes, rinse and dry the waste polyester products after soaking, and then irradiate the waste polyester products after the above-mentioned treatment. The time is 5 minutes;

[0031]S2. Put 200 parts of waste polyester products treated in S1 into a reactor for heating. After heating the waste polyester products to prepare polyester melt, add 20 to 30 parts of hydroquinone-bis(β-hydroxyethyl Base) ether, 15 parts of diisocyanate, 20 parts of high-efficiency antibacterial agent, 3 parts of acrylate-β hydroxypropyl ester and 5 parts of benzophthalein peroxide, mix and stir to obtain the mixture; then the...

Embodiment 2

[0045] A viscosifying spinning process for recycling waste polyester, comprising the following preparation steps:

[0046] S1. Soak the waste polyester products after cleaning and drying in benzalkonium bromide solution for 6 minutes, rinse and dry the waste polyester products after soaking, and then irradiate the waste polyester products after the above treatment, The time is 8 minutes;

[0047] S2. Put 200 parts of waste polyester products treated in S1 into the reactor for heating, and after heating the waste polyester products to prepare polyester melt, add 25 parts of hydroquinone-bis(β hydroxyethyl) into the reactor Ether, 18 parts of diisocyanate, 22 parts of high-efficiency antibacterial agent, 4 parts of acrylate-β-hydroxypropyl ester and 6 parts of benzophthalein peroxide, mix and stir evenly to obtain a mixture; then the mixture in the reactor is beaten, and after the beating is completed Raise the temperature in the reactor to 240°C, and react for 1 hour under cer...

Embodiment 3

[0061] A viscosifying spinning process for recycling waste polyester, comprising the following preparation steps:

[0062] S1. Soak the waste polyester products after cleaning and drying in benzalkonium bromide solution for 8 minutes, rinse and dry the waste polyester products after soaking, and then irradiate the waste polyester products after the above treatment, The time is 10 minutes;

[0063] S2. Put 200 parts of waste polyester products treated in S1 into the reactor for heating, and after heating the waste polyester products to prepare polyester melt, add 30 parts of hydroquinone-bis(β hydroxyethyl) into the reactor Ether, 20 parts of diisocyanate, 25 parts of high-efficiency antibacterial agent, 5 parts of β-hydroxypropyl acrylate and 8 parts of benzophthalein peroxide, mix and stir evenly to obtain a mixture; then beat the mixture in the reactor, after beating Raise the temperature in the reactor to 250°C, and react for 2 hours under certain pressure conditions, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com