Vanadium-titanium catalyst as well as preparation method and application thereof

A catalyst, vanadium-titanium technology, which is applied in the field of vanadium-titanium catalyst and its preparation, can solve the problems that low-temperature activity needs to be further improved, is not suitable for large-scale popularization and use, and has complex components, achieves good low-temperature activity, improves catalytic activity, and widens temperature window effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

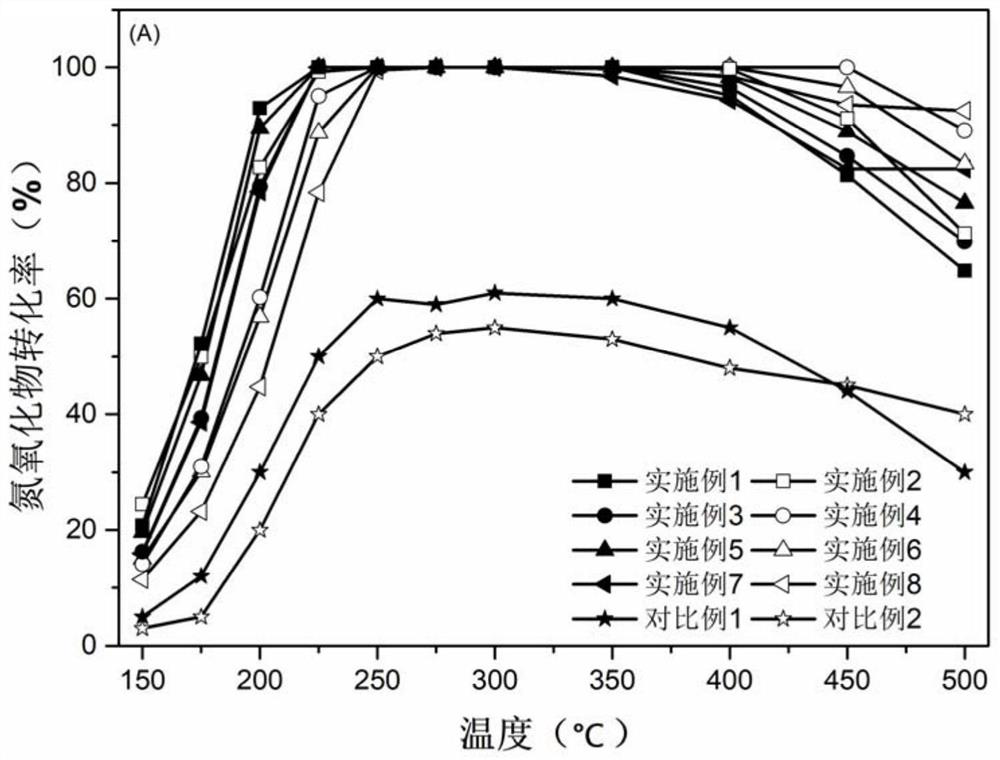

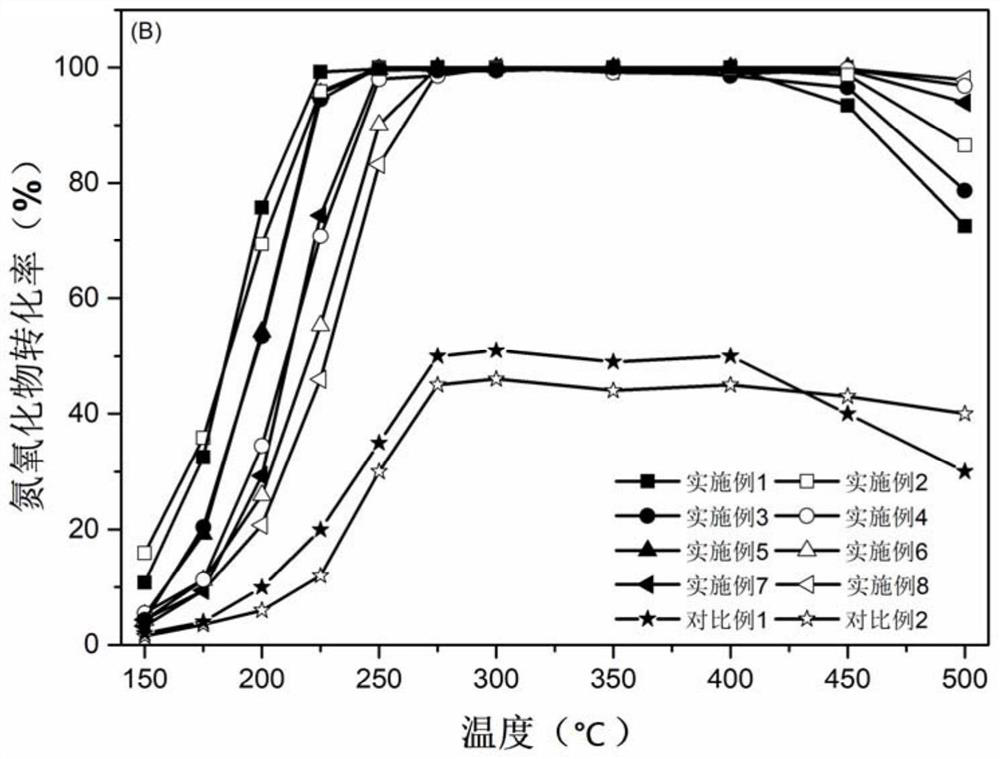

Embodiment 1

[0045] This embodiment provides a vanadium-titanium catalyst and a preparation method thereof, the vanadium-titanium catalyst comprising TiO 2 carrier, V 2 o 5 Active ingredients and MoO 3 Auxiliary, wherein, the V 2 o 5 Active ingredients and MoO 3 After the combination of additives, the TiO is loaded on the 2 support, with the TiO 2 The mass of the carrier is 100% in terms of the V 2 o 5 The mass of active ingredient is 2.5%, the MoO 3 The mass of auxiliary agent is 6%.

[0046] Described preparation method comprises the steps:

[0047] (1) according to above-mentioned proportioning weighing ammonium metavanadate as vanadium source and ammonium molybdate as molybdenum source, be 2:1 to weigh oxalic acid and be dissolved in 100mL deionized water according to the mol ratio of oxalic acid and ammonium metavanadate, then Add the weighed ammonium metavanadate and ammonium molybdate and mix uniformly to obtain the active component solution;

[0048] (2) Weigh TiO accor...

Embodiment 2

[0050] This embodiment provides a vanadium-titanium catalyst and a preparation method thereof, except that MoO in the vanadium-titanium catalyst 3 Replace with WO of equal quality 3 , correspondingly ammonium molybdate in the preparation method is replaced by ammonium metatungstate, other conditions are exactly the same as in Example 1, denoted as 2.5wt% V 2 o 5 -6wt% WO 3 / TiO 2 .

Embodiment 3

[0052] This embodiment provides a vanadium-titanium catalyst and a preparation method thereof, except that V in the vanadium-titanium catalyst 2 o 5 The mass percentage of MoO is replaced by 2.5% to 1.5%, MoO 3 The mass percent composition of is replaced by 6% by 10%, and the quality of ammonium metavanadate and ammonium molybdate in the preparation method is adjusted accordingly, other conditions are exactly the same as embodiment 1, denoted as 1.5wt% V 2 o 5 -10wt%MoO 3 / TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com