Impregnation machine for producing small power adapter

A power adapter and a small technology, applied in the field of impregnation machines, can solve the problems of incomplete soaking of adapter components, damage to the user's working environment, and harm to the user's health, etc., and achieve the effects of convenient processing, efficient air-drying, and comprehensive soaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

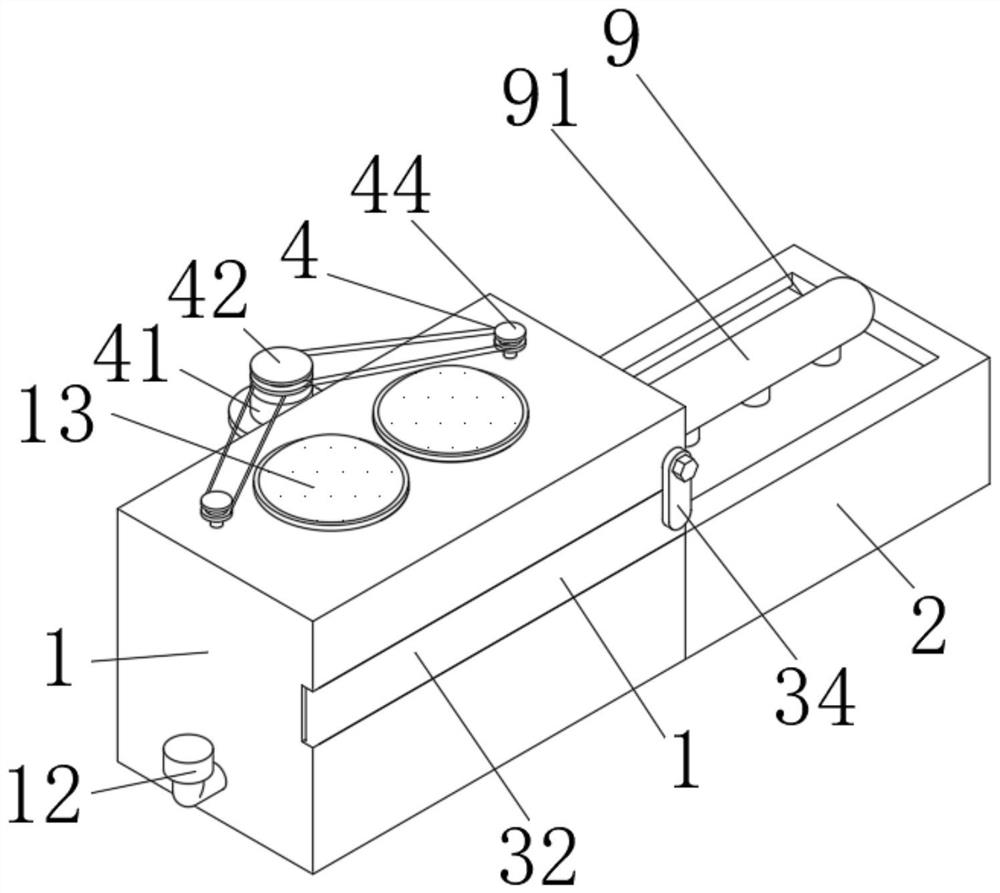

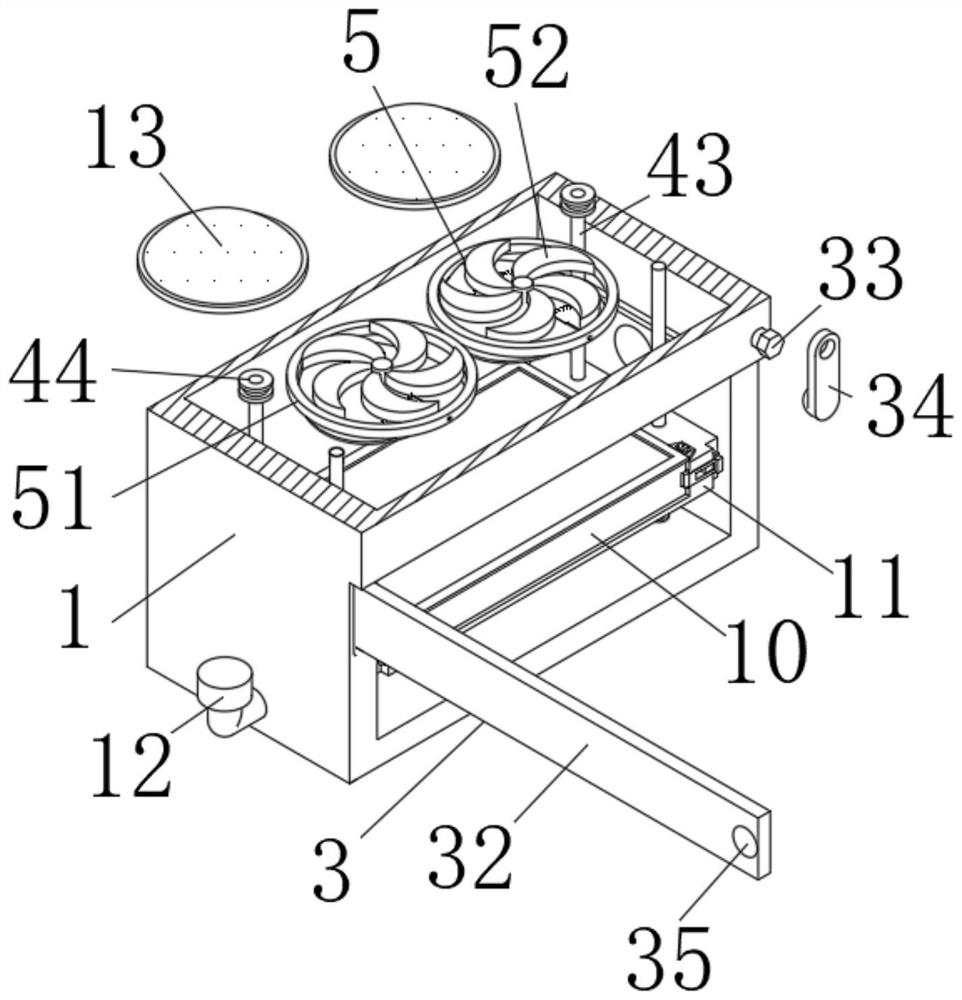

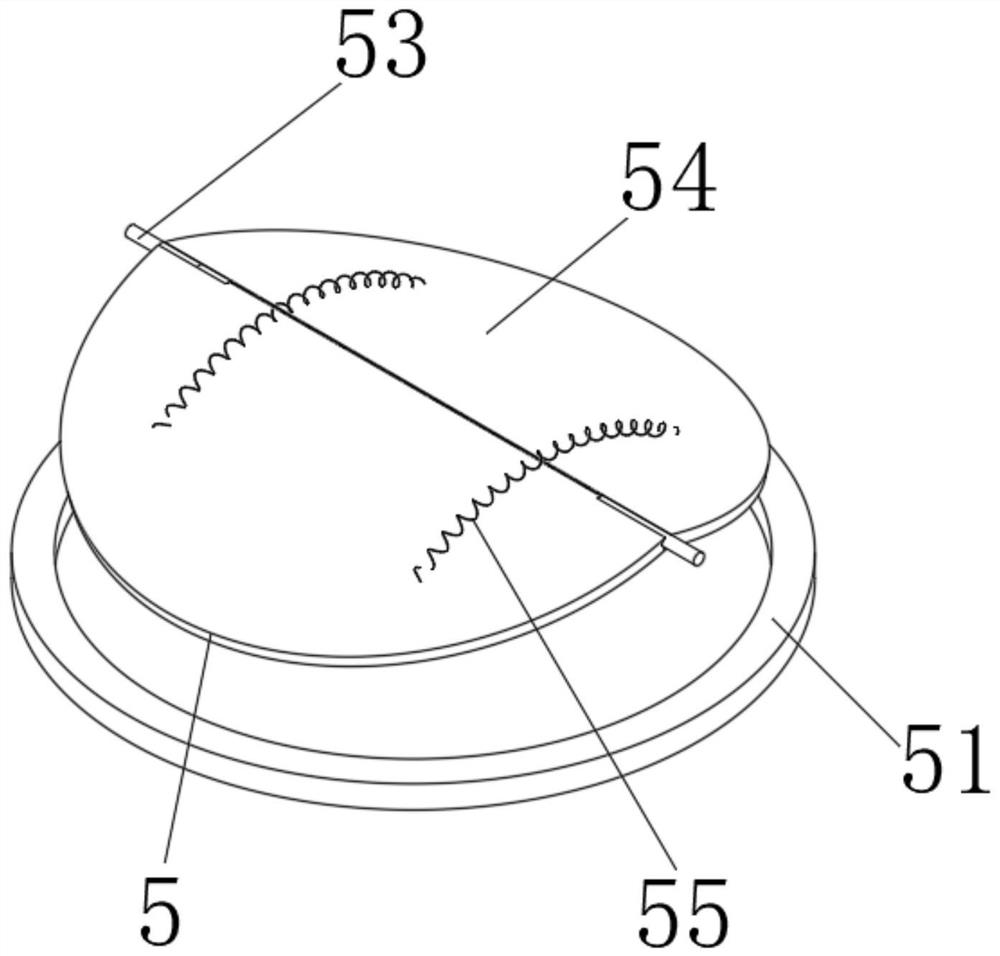

[0034] see Figure 1-10, the present invention provides a technical solution: a small impregnation machine for power adapter production, including a soaking box 1, a purification box 2 is fixedly connected to the right side of the soaking box 1, and a lifting table 11 is provided in the inner cavity of the soaking box 1, and the lifting table 11 is The inner cavity of the platform 11 is provided with a storage net box 10, the inner cavity of the soaking box 1 is provided with a sealing mechanism 3, and the back surface of the soaking box 1 is provided with a lifting mechanism 4, and the lifting mechanism 4 includes a top mounted on the back surface of the soaking box 1. Motor 41, the output shaft of motor 41 is fixedly connected with double-groove belt pulley 42, and the two ends of soaking box 1 top rear side all run through and are provided with threaded driving rod 43, and lifting table 11 is threaded on the surface of threaded driving rod 43, and threaded drive The bottom ...

Embodiment 2

[0042] see Figure 1-10 , the present invention provides a technical solution: a small impregnation machine for power adapter production, including a soaking box 1, a purification box 2 is fixedly connected to the right side of the soaking box 1, and a lifting table 11 is provided in the inner cavity of the soaking box 1, and the lifting table 11 is The inner cavity of the platform 11 is provided with a storage net box 10, the inner cavity of the soaking box 1 is provided with a sealing mechanism 3, and the back surface of the soaking box 1 is provided with a lifting mechanism 4, and the lifting mechanism 4 includes a top mounted on the back surface of the soaking box 1. Motor 41, the output shaft of motor 41 is fixedly connected with double-groove belt pulley 42, and the two ends of soaking box 1 top rear side all run through and are provided with threaded driving rod 43, and lifting table 11 is threaded on the surface of threaded driving rod 43, and threaded drive The bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com