Method for forming conductive layer using atomic layer deposition process

An atomic layer, silicon atom technology, applied in metal material coating process, coating, circuit and other directions, can solve the problems of increased silicon loss, difficulty in forming a titanium silicide layer, and inferior junction leakage characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

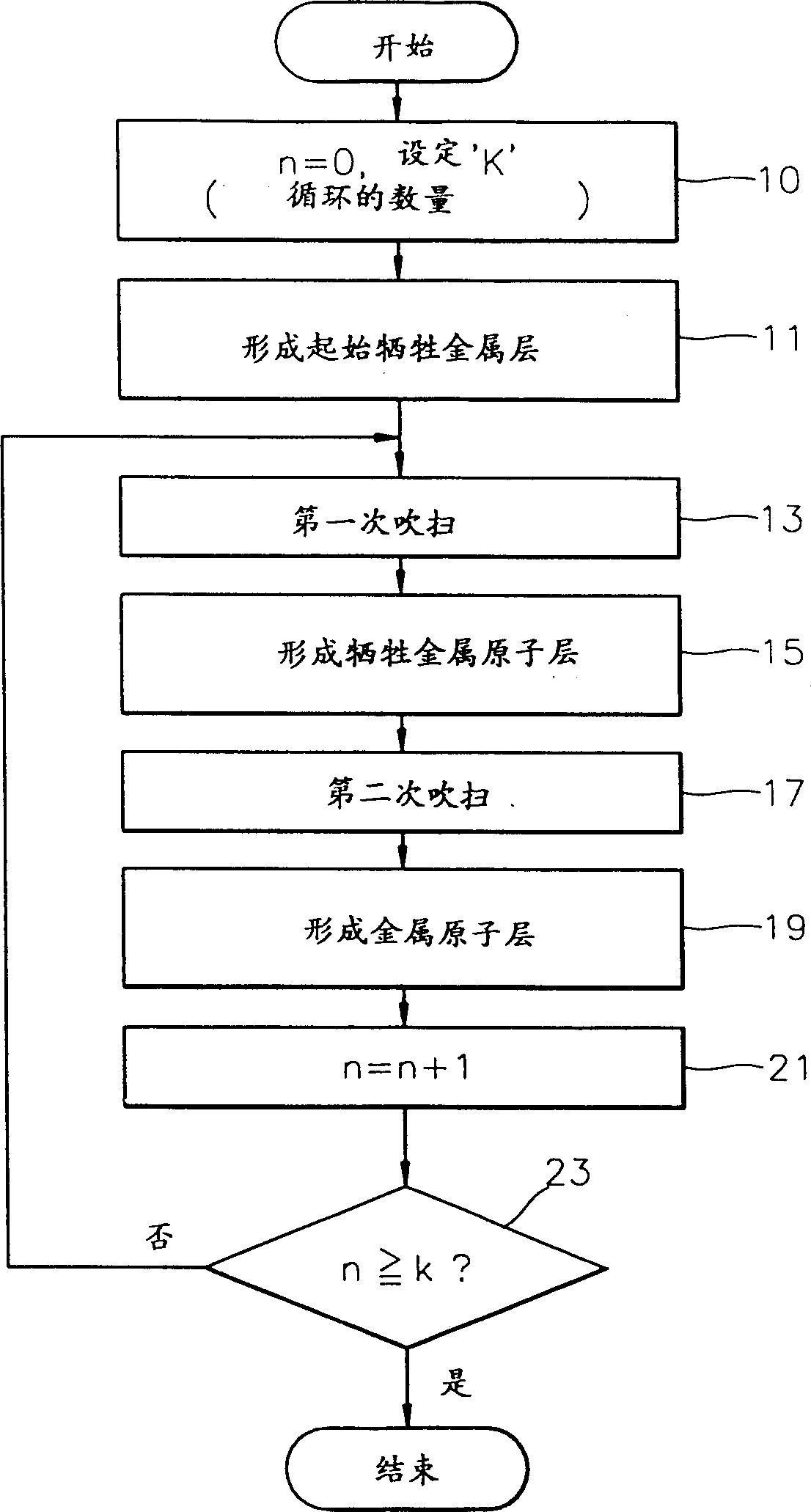

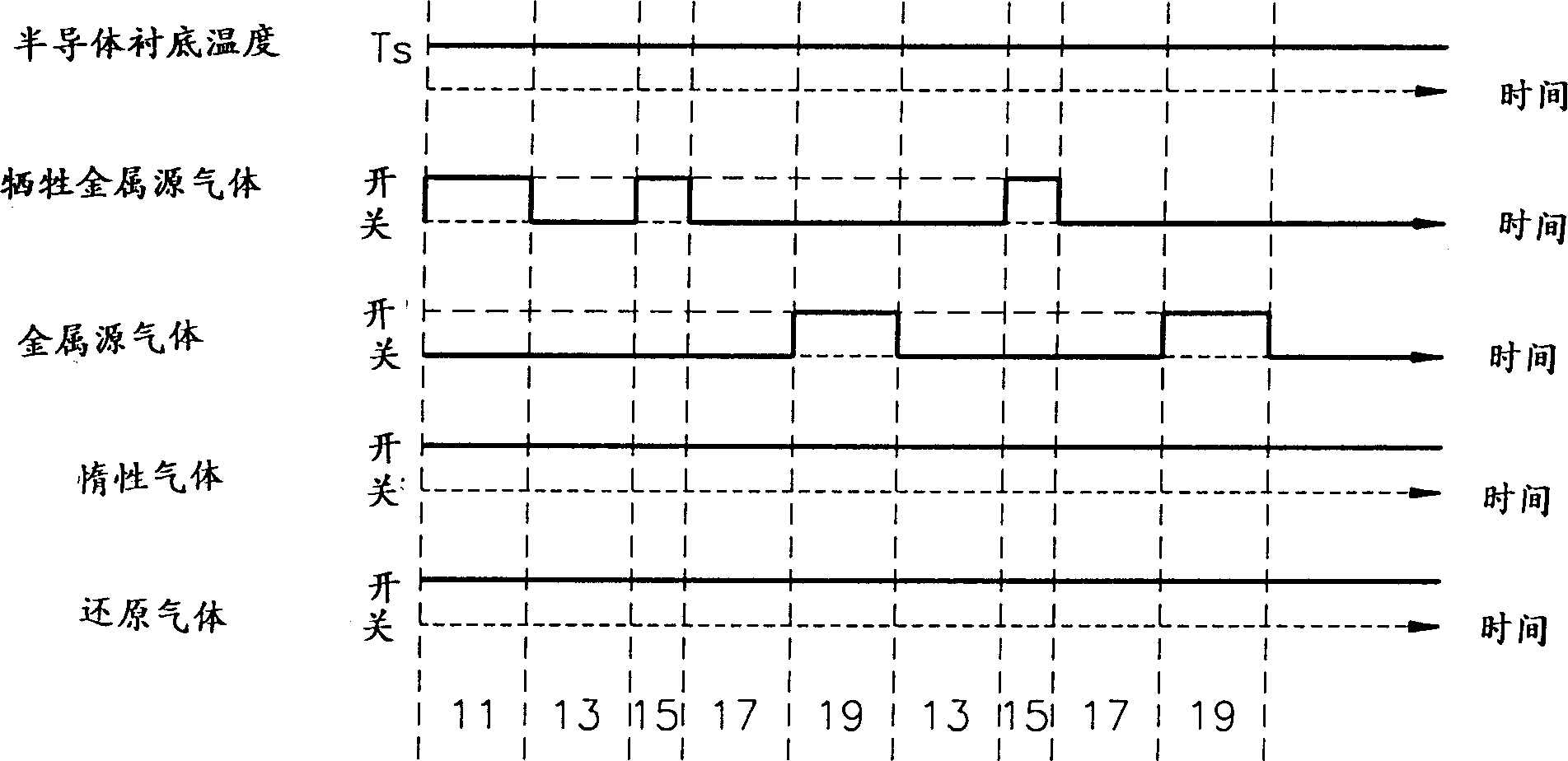

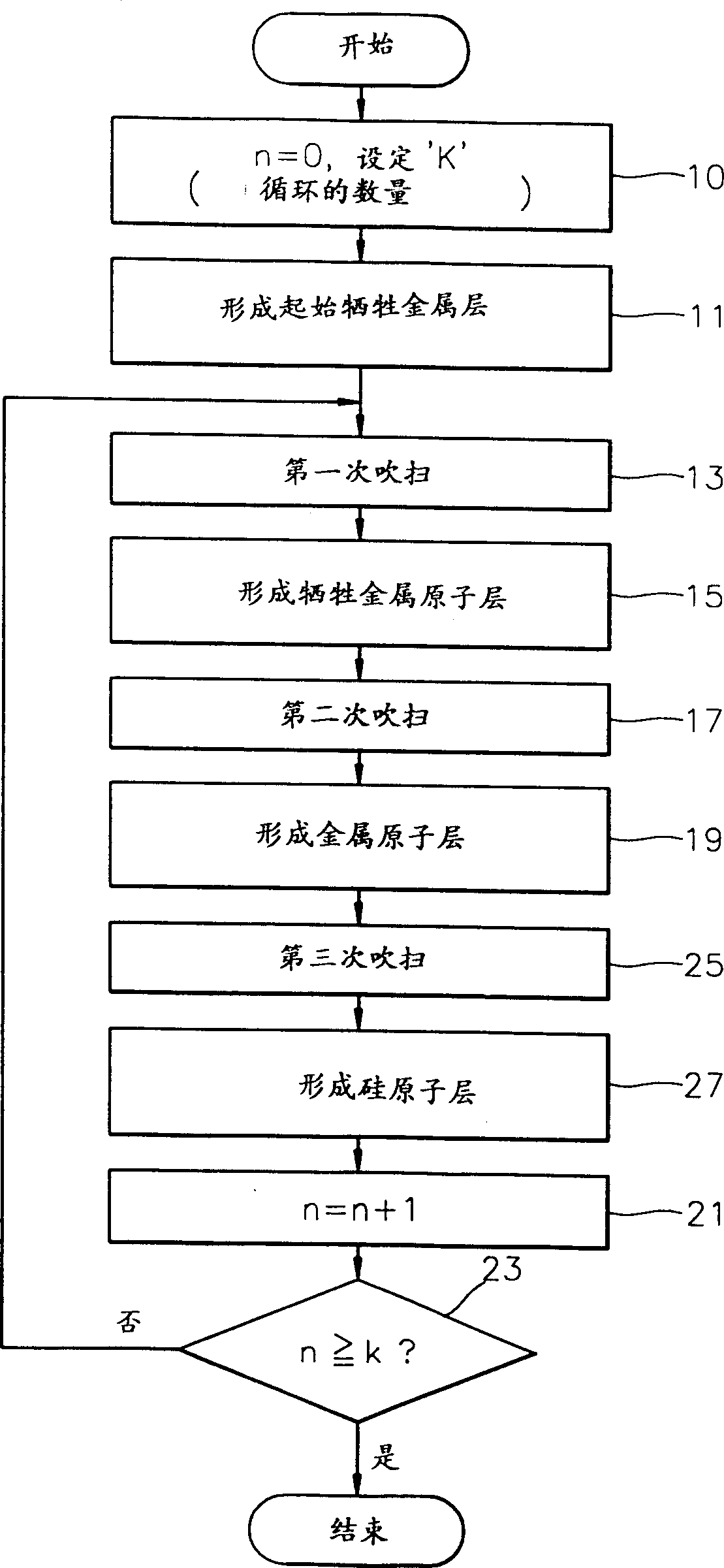

Method used

Image

Examples

Embodiment Construction

[0020] see Figure 5 , The device for forming the conductive layer according to the present invention includes a reaction chamber 51, a susceptor 53 installed at the bottom of the reaction chamber 51 for positioning a semiconductor substrate 55 on top of the susceptor 53, and mounted on the susceptor 53 for facing the reaction chamber 51. A shower head 57 for injecting reaction gas, and a vacuum rod 59 connected with the reaction chamber 51 to control the pressure in the reaction chamber 51. In the present invention, the shower head 57 includes two gas inlets A and B separated from each other. The metal source gas and the inert gas are injected into the reaction chamber 51 through the gas inlet A, and the silicon source gas, the sacrificial metal source gas and the reducing gas are injected into the reaction chamber 51 through the gas inlet B. This makes it possible to confine the reaction of the gas to one of the inlets A and B before reaching the reaction chamber 51 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com