Manufacturing equipment and manufacturing method of oxygen sensor seat assembly

An oxygen sensor and manufacturing equipment technology, applied in manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of entering the market, too many substandard products, unable to detect in time, etc., to improve product quality and strong traceability , easy to realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

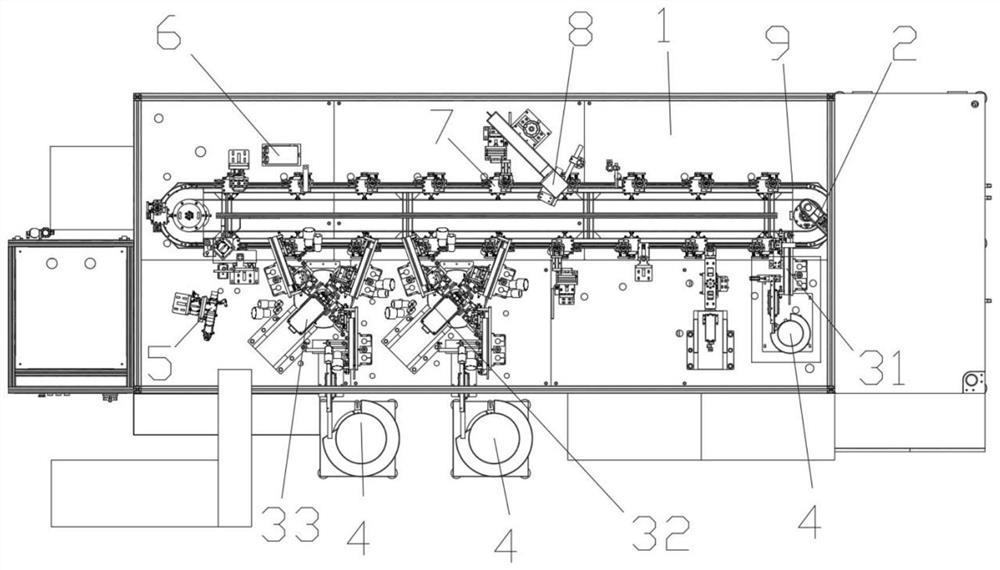

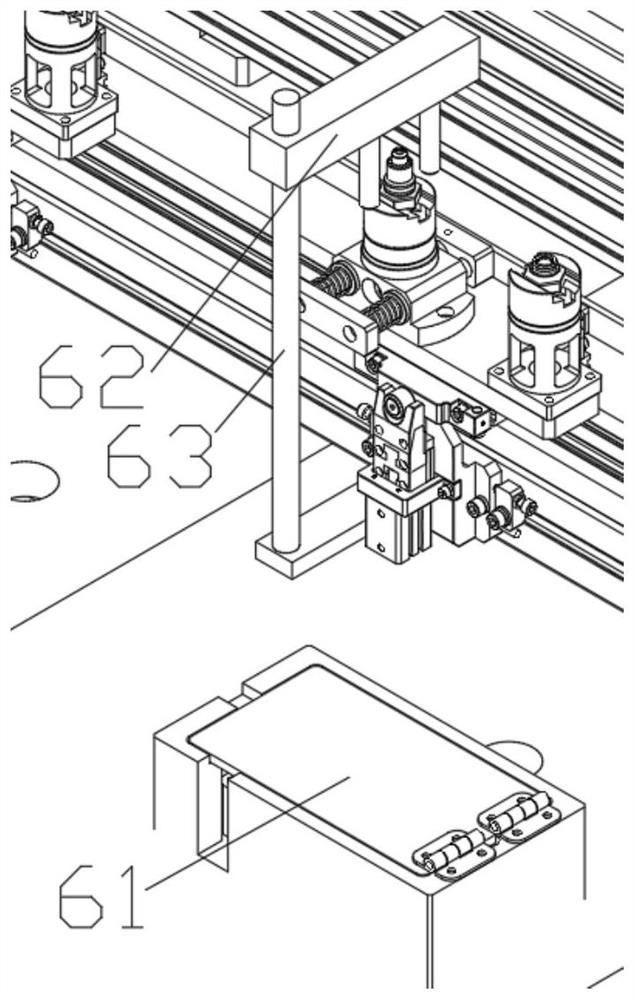

[0027] A preferred embodiment of the present invention is a manufacturing method of an oxygen sensor seat assembly, and the supporting production equipment of the method is such as figure 1 As shown, it includes a mounting table 1 and an endless conveyor belt 9, and along the conveying direction of the endless conveyor belt 9, a feeding manipulator 2, a first press-fitting device 31, a second press-fitting device 32, a third press-fitting device 33, Laser welding device 5, eddy current detection device 6, laser coding device 7, code scanning device 8, blanking manipulator, the device arranged along the conveying direction of the endless conveyor belt 9 and the endless conveyor belt 9 are all fixed on the installation platform 1, and Control via control unit. The control device is preferably a PLC.

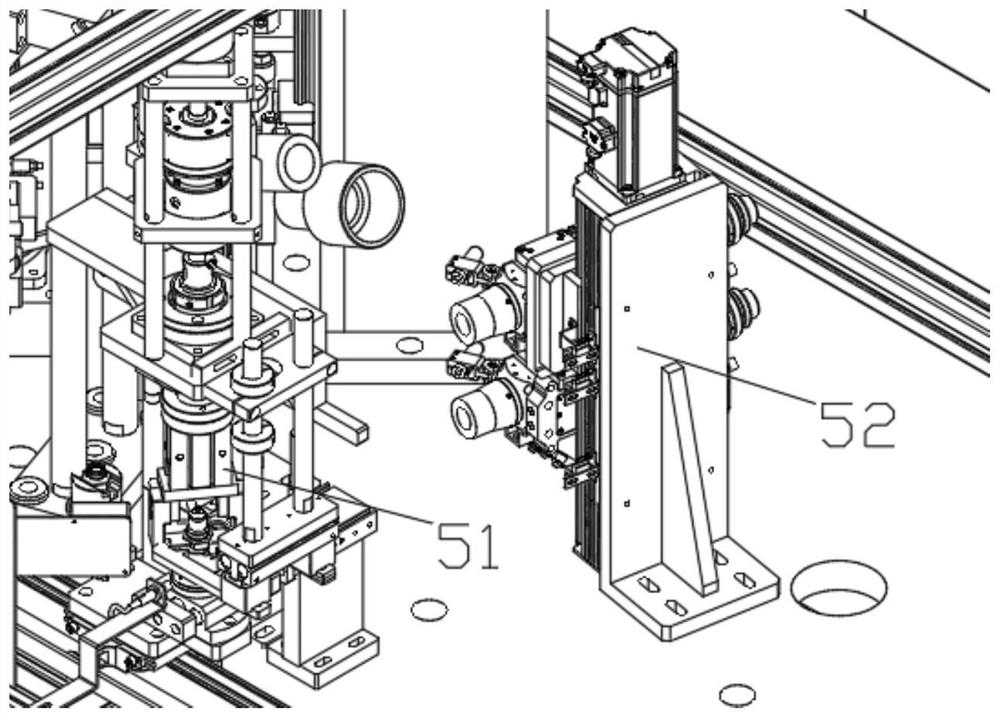

[0028] Such as Figure 4 As shown, the first press-fit device 31 includes a press-fit manipulator 41, a profiling suction head 43, a stamping device 42, a vibrating tray 4, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com