X-shaped large arm for laser cutting of industrial robot

An industrial robot and laser cutting technology, applied in the field of X-shaped arms, can solve the problems of deviation of the robot end from the theoretical coordinate point and positioning error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

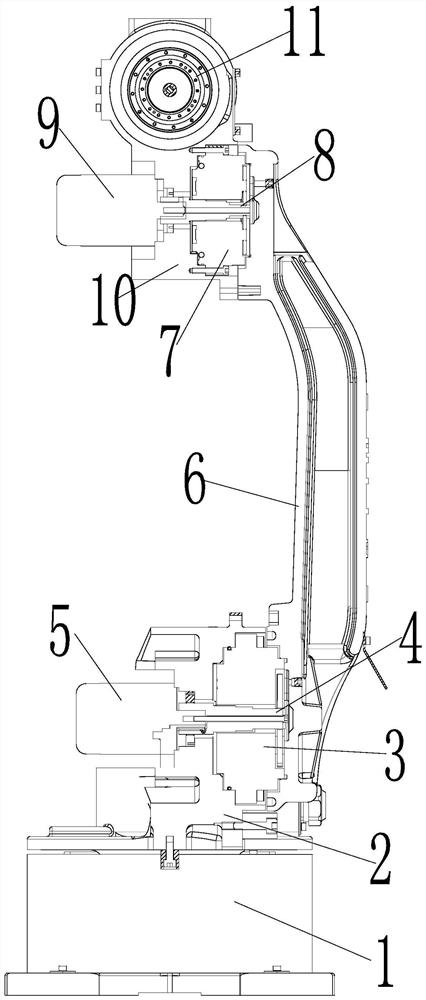

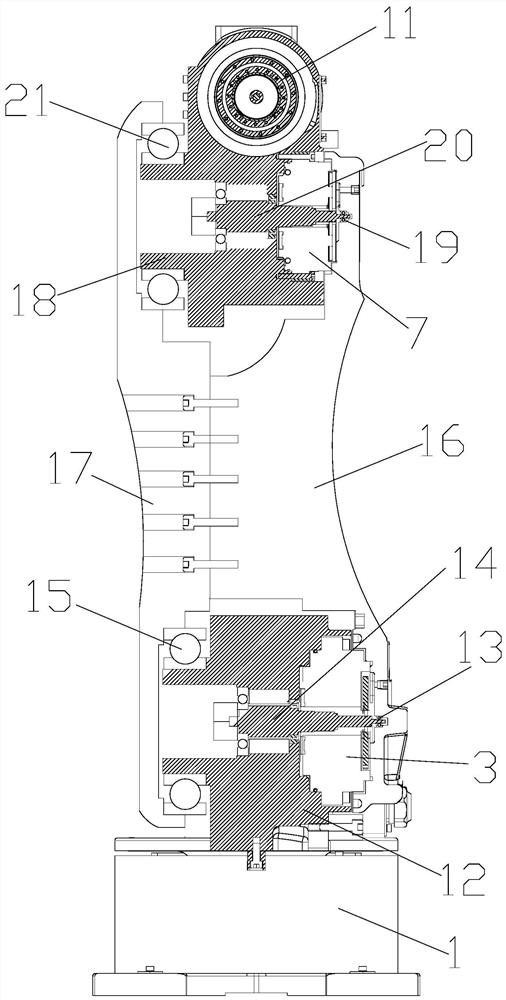

[0019] like figure 2 As shown, an X-shaped arm of an industrial robot used for laser cutting, J1 axis 1 is the joint axis 1 of the industrial robot, and the two ends of J2 casting workpiece 12 are respectively installed with integrated servo motor J2 input gear shaft 14, J2RV reducer 3 and Load bearing J2 bearing 15. The outer ring of the J2 gear shaft locating bearing 13, the J2 gear shaft locating bearing 19 locates the X-type big arm right half 16, and the outer ring of the J2 bearing 15, J3 bearing 21 locates the X-type big arm left half 17. The integrated servo motor J2 input gear shaft 14 directly drives the J2RV reducer 3, the integrated servo motor J2 input gear shaft 14 gear decelerates through the meshing J2RV reducer 3, and the output end of the J2RV reducer 3 drives the right half of the J3 axis X-shaped boom 16, The left half of the X-shaped upper arm moves 17. The two ends of J4 casting workpiece 18 are respectively installed with integrated servo motor J3 inp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com