Production process and production device of wide-distribution cobaltosic oxide

A technology of cobalt tetroxide and production process, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., and can solve the problem that the particle size of the product is difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

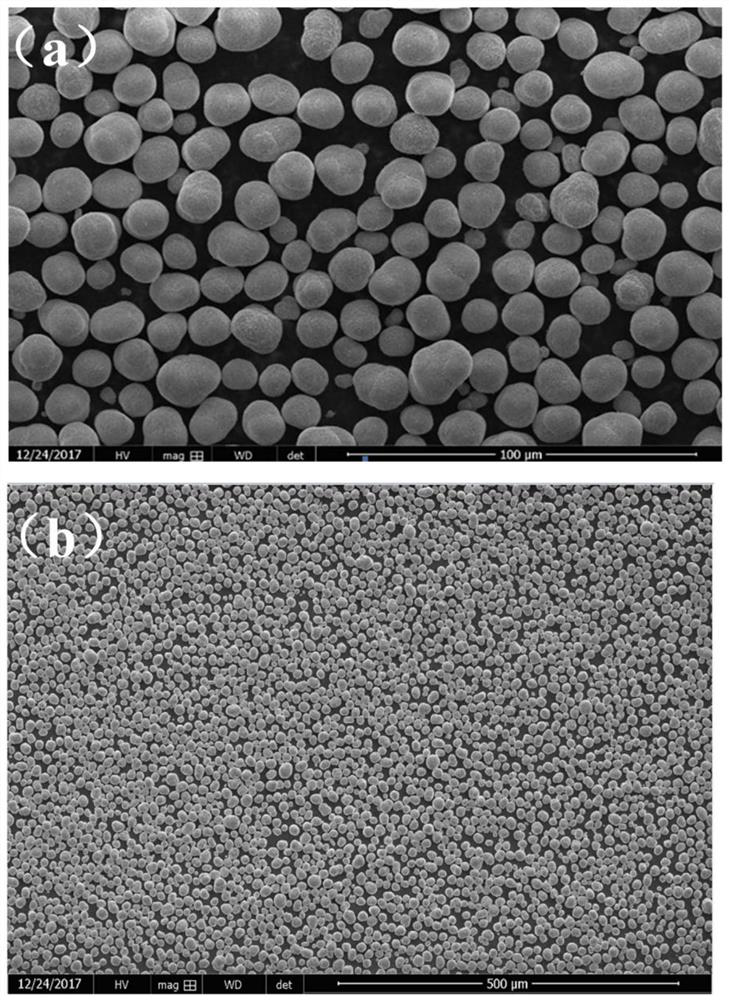

Embodiment 1

[0040] Customers require broad-distribution cobalt tetroxide products to have the following properties: consistent primary crystal form, D00≥3.0μm, D50: 13~15μm, (D90-D50)=b>5.0μm, (D50-D10)=a>3.5μm;

[0041] In order to produce the tricobalt tetroxide product with above-mentioned properties, the specific production process that adopts is:

[0042]Step 1. Continuously add the cobalt chloride solution with a cobalt ion concentration of 0.4mol / L into the reactor at a rate of 550L / h, and add a 1mol / L precipitant while keeping the flow rate of the cobalt salt solution constant Solution (ammonium carbonate solution), the pH value of the flow control system by adjusting the ammonium carbonate solution is 7~8, then stirs with the speed of 150r / min, and at 50 ℃, until the particle diameter of the first cobalt salt precipitate obtained Until the first particle size value is reached, where the first particle size value satisfies D50≥8.0μm;

[0043] Step 2. Separating the first cobalt s...

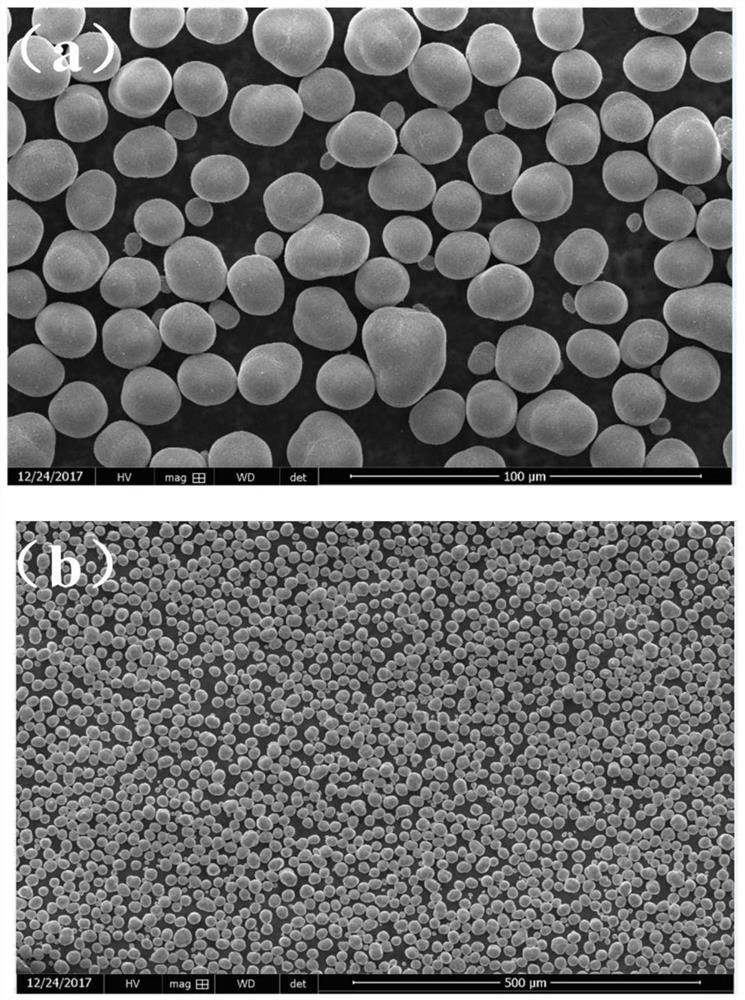

Embodiment 2

[0052] Customers require broad-distribution cobalt tetroxide products to have the following properties: consistent primary crystal form, D00≥6.0μm, D50: 17~18μm, (D90-D50)=b>7.0μm, (D50-D10)=a>5.0μm;

[0053] In order to produce the tricobalt tetroxide product with above-mentioned properties, the specific production process that adopts is:

[0054] Step 1. Continuously add the cobalt sulfate solution with a cobalt ion concentration of 1.2mol / L into the reactor at a rate of 600L / h, and add a 2mol / L precipitant solution while keeping the flow rate of the cobalt salt solution constant (ammonium bicarbonate solution), the pH value of the flow control system by regulating the ammonium bicarbonate solution is 7~8, then stirs with the speed of 180r / min, and at 55 ℃, until the particle size of the first cobalt salt precipitate obtained until the particle size reaches the first particle size value, where the first particle size value satisfies D50≥13.0μm;

[0055] Step 2. Separating t...

Embodiment 3

[0064] Customers require broad-distribution cobalt tetroxide products to have the following properties: consistent primary crystal form, D00≥6.0μm, D50: 17~18μm, (D90-D50)=b>7.0μm, (D50-D10)=a>5.0μm;

[0065] In order to produce the tricobalt tetroxide product with above-mentioned properties, the specific production process that adopts is:

[0066] Step 1. Continuously add the cobalt nitrate solution with a cobalt ion concentration of 2.0mol / L into the reactor at a rate of 700L / h, and add a 3mol / L precipitant solution while keeping the flow rate of the cobalt salt solution constant (sodium carbonate solution), the pH value of the flow control system by regulating the sodium carbonate solution is 7~8, then stirs with the speed of 200r / min, and at 60 ℃, until the particle diameter of the first cobalt salt precipitate that obtains reaches Up to the first particle size value, where the first particle size value satisfies D50≥13.0μm;

[0067] Step 2. Separating the first cobalt sa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap