High-performance aliphatic polyester elastomer and preparation method thereof

An aliphatic polyester, high-performance technology, used in the field of thermoplastic elastomers, can solve the problem of low tensile strength at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

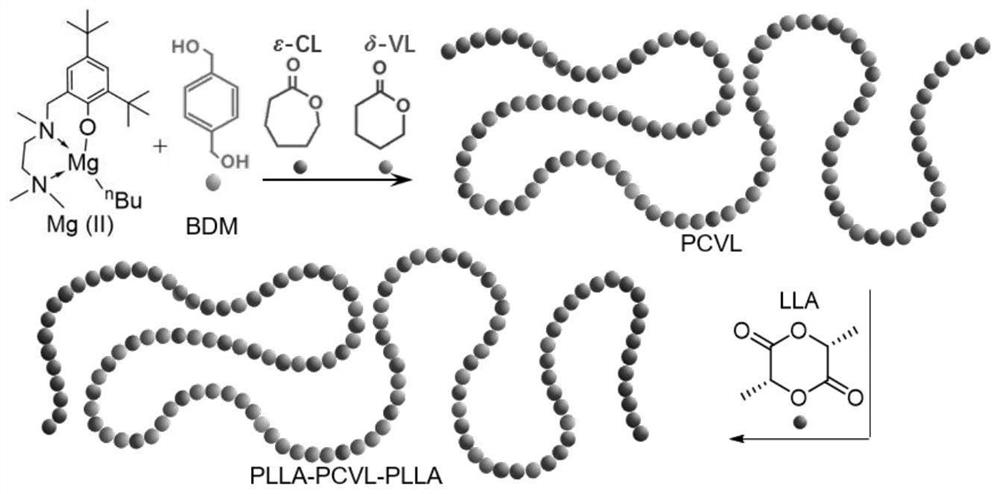

[0076] The present invention provides the preparation method of high-performance aliphatic polyester elastomer described in above-mentioned technical scheme, comprises the following steps:

[0077] mixing ε-caprolactone, δ-valerolactone, a catalyst, an initiator and an organic solvent to perform a first polymerization reaction to obtain a polymerization product;

[0078] Mixing the polymerized product with the lactide monomer to perform a second polymerization reaction to obtain a high-performance aliphatic polyester elastomer;

[0079] The structure of the catalyst is

[0080] The initiator comprises dibasic alcohol, and described dibasic alcohol comprises

[0081] The lactide monomer is L-lactide, D-lactide, racemic lactide or glycolide;

[0082] The molar ratio of the initiator to the catalyst is (0.5~10):1; the molar ratio of the δ-valerolactone to the ε-caprolactone is (0.5~10):1; the lactide monomer and The molar ratio of ε-caprolactone is (0.5-10):1; the molar ...

Embodiment 1

[0107] In the present embodiment, the molar ratio of catalyst: terephthalic acid: ε-CL: δ-VL: LLA (L-type lactide) is 1:1:200:228:50, and the specific steps are:

[0108] Weigh 10mg (0.025mmol) of the catalyst and dissolve it in 500μL of anhydrous toluene, weigh 3.5mg (0.025mmol) of terephthalamide and add it to the obtained catalyst solution, then add 3.5mL of anhydrous toluene, react for one minute, and simultaneously add 529μLε- CL (5.0mmol) and 520μL δ-VL (5.7mmol), the polymerization reaction was started for 35min, and after the polymerization was completed, the 200 / 228 PCVL, add a dichloromethane solution containing 180mg (1.25mmol) LLA to the obtained product, and carry out polymerization for 15min. After the monomer is completely converted, add petroleum ether to quench the polymer, pump it to constant weight, and name the obtained elastomer sample for 25 PLLA- 200 / 228 PCVL- 25 PLLA, the structural formula is:

[0109]

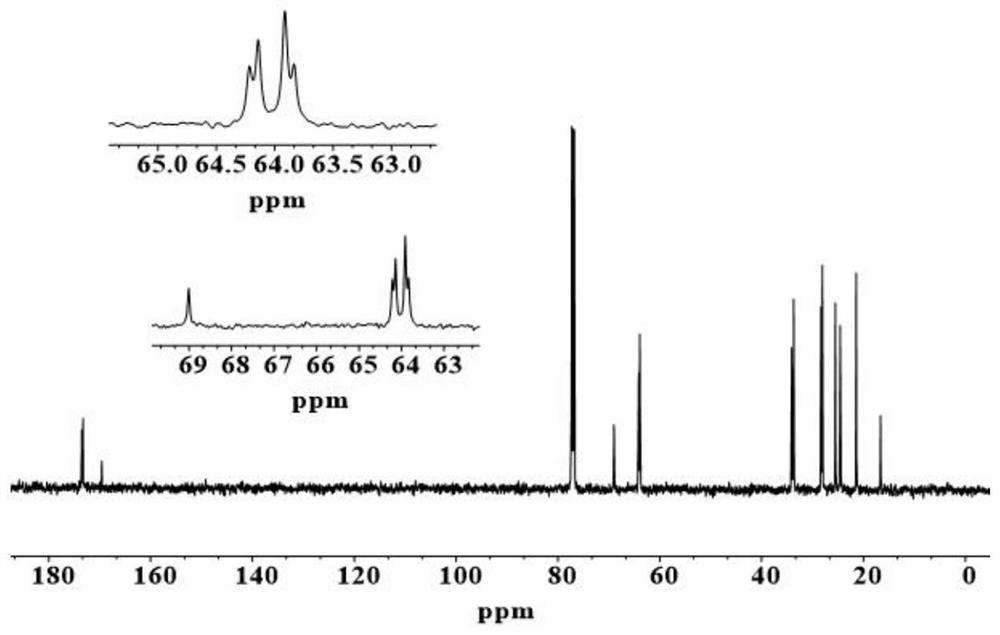

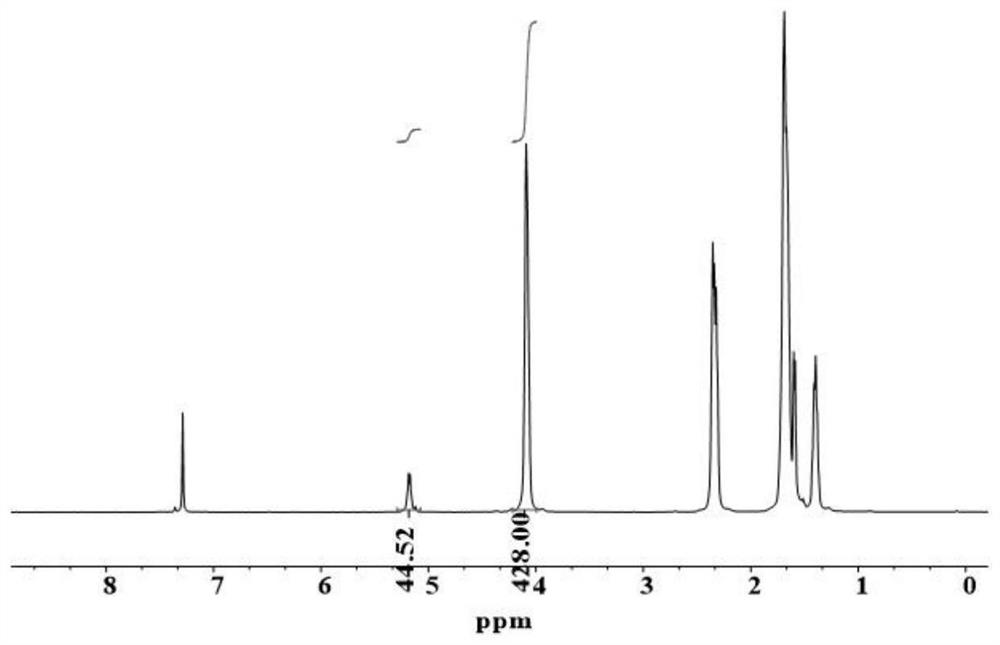

[0110] Characterization and Testing...

Embodiment 2

[0115] In the present embodiment, the molar ratio of catalyst: terephthalic acid: ε-CL: δ-VL: LLA (L-type lactide) is 1:1:300:342:50, and the specific steps are:

[0116] Weigh 6.7mg (0.0167mmol) of catalyst and dissolve it in 500μL of anhydrous toluene, weigh 2.3mg (0.0167mmol) of terephthalenedimethanol and add it to the obtained catalyst solution, then add 3.5mL of anhydrous toluene, react for one minute, and add 529μLε-CL (5.0mmol) and 520μLδ-VL (5.7mmol), start the polymerization reaction for 60min, and obtain after the polymerization is completed 300 / 342 PCVL, add a dichloromethane solution containing 120mg (0.835mmol) LLA to the obtained product, carry out polymerization for 18 minutes, after the monomer is completely converted, add petroleum ether to quench the polymer, pump to constant weight, and the elastomer sample obtained is named as 25 PLLA- 300 / 342 PCVL- 25 PLLA, the structural formula is:

[0117]

[0118] Characterization and Testing

[0119] 1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com