Low-permeability fluororubber product material

A fluororubber and low-permeability technology, which is applied in the field of fluororubber product materials and low-permeability fluororubber product materials, can solve the problems of poor workmanship, low product qualification rate, high material cost, etc., achieve good methanol and ethanol fuel performance, improve Good mold release performance and compressive stress relaxation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

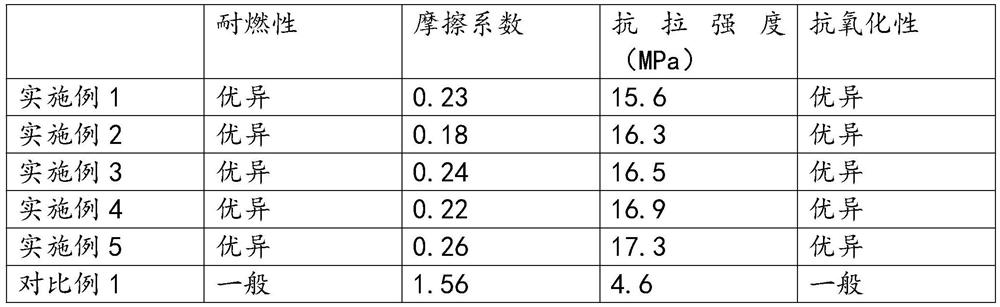

Examples

Embodiment 1

[0029] A low-permeability fluororubber product material, including the following raw materials in parts by weight: 84 parts of fluororubber, 4 parts of calcium silicate, 1.5 parts of magnesium oxide, 4 parts of calcium hydroxide, 0.3 parts of WS280, 0.3 parts of iron oxide red, modified 8 parts of molybdenum disulfide, 12 parts of nano inorganic filler, 2 parts of modified diatomite, 2 parts of modified white carbon black;

[0030] The preparation process of the low-permeability fluororubber product material comprises the following steps:

[0031] The first step: the preparation of synthetic rubber: send all the raw materials into the internal mixer according to the above weight parts, and detect the hardness, strength and elongation after obtaining the synthetic rubber through the internal mixer, and filter after detection, wherein, Synthetic rubber with a hardness of 65 degrees, strength ≥ 10MPa, and elongation ≥ 175% is qualified synthetic rubber;

[0032] The second step:...

Embodiment 2

[0046] A low-permeability fluororubber product material, comprising the following raw materials in parts by weight: 85 parts of fluororubber, 5 parts of calcium silicate, 1.8 parts of magnesium oxide, 5 parts of calcium hydroxide, 0.4 parts of WS280, 0.4 parts of iron oxide red, modified 9 parts of molybdenum disulfide, 13 parts of nano inorganic filler, 3 parts of modified diatomite, 3 parts of modified white carbon black;

[0047] The preparation process of the low-permeability fluororubber product material comprises the following steps:

[0048] The first step: the preparation of synthetic rubber: send all the raw materials into the internal mixer according to the above weight parts, and detect the hardness, strength and elongation after obtaining the synthetic rubber through the internal mixer, and filter after detection, wherein, Synthetic rubber with a hardness of 68 degrees, a strength ≥ 10 MPa, and an elongation ≥ 175% is a qualified synthetic rubber;

[0049] The sec...

Embodiment 3

[0063] A low-permeability fluororubber product material, comprising the following raw materials in parts by weight: 87 parts of fluororubber, 5 parts of calcium silicate, 2.0 parts of magnesium oxide, 5 parts of calcium hydroxide, 0.5 part of WS280, 0.5 part of iron oxide red, modified 10 parts of molybdenum disulfide, 16 parts of nano inorganic filler, 3 parts of modified diatomite, 3 parts of modified white carbon black;

[0064] The preparation process of the low-permeability fluororubber product material comprises the following steps:

[0065] The first step: the preparation of synthetic rubber: send all the raw materials into the internal mixer according to the above weight parts, and detect the hardness, strength and elongation after obtaining the synthetic rubber through the internal mixer, and filter after detection, wherein, Synthetic rubber with a hardness of 70 degrees, strength ≥ 10MPa, and elongation ≥ 175% is qualified synthetic rubber;

[0066] The second step:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com