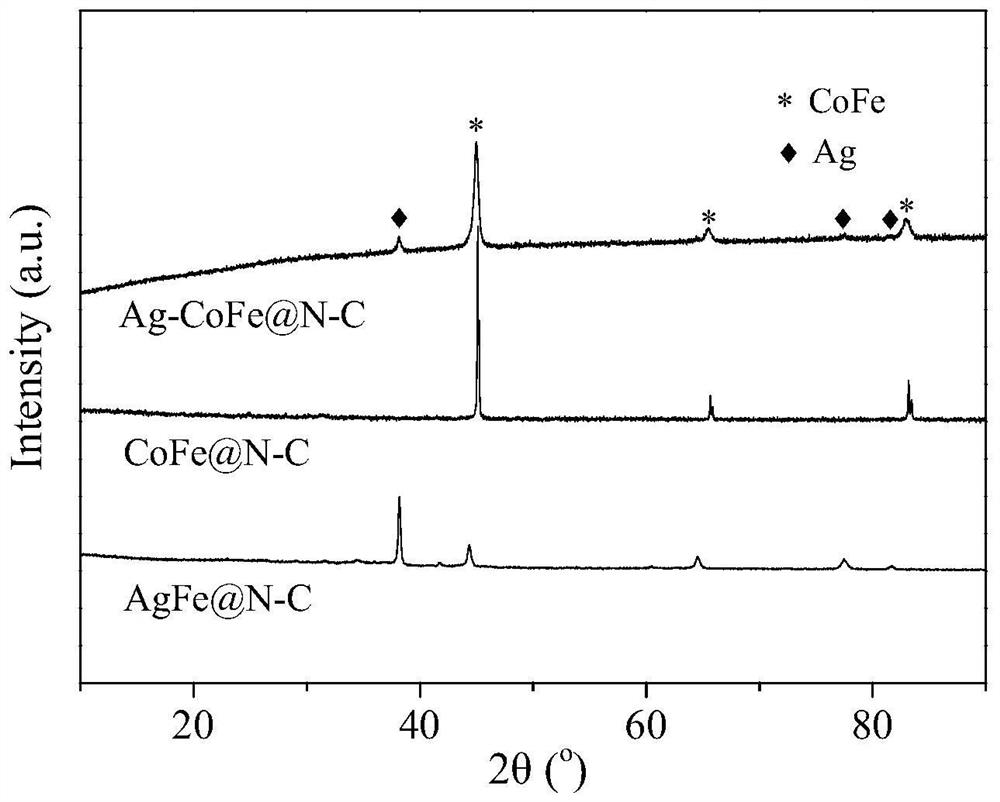

Preparation method of a transition metal-nitrogen co-doped carbon material oxygen reduction/oxygen evolution bifunctional catalyst

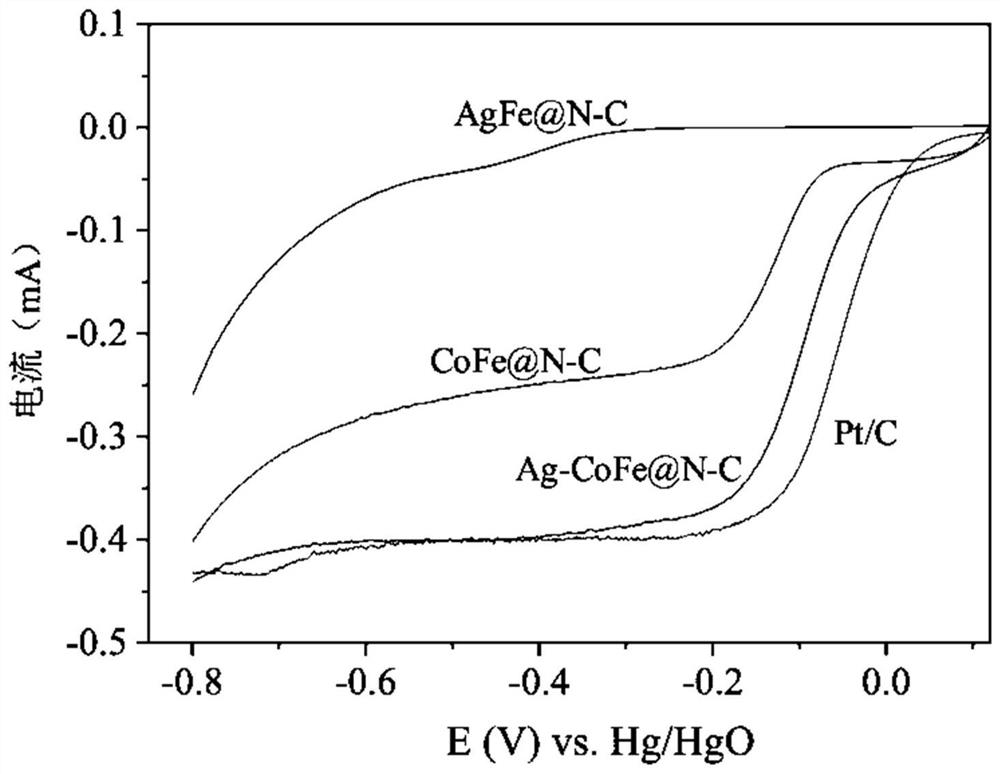

A dual-functional catalyst and transition metal technology, applied in physical/chemical process catalysts, chemical instruments and methods, electrolysis processes, etc., to achieve good methanol resistance, optimized electronic structure and geometric atom rearrangement, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

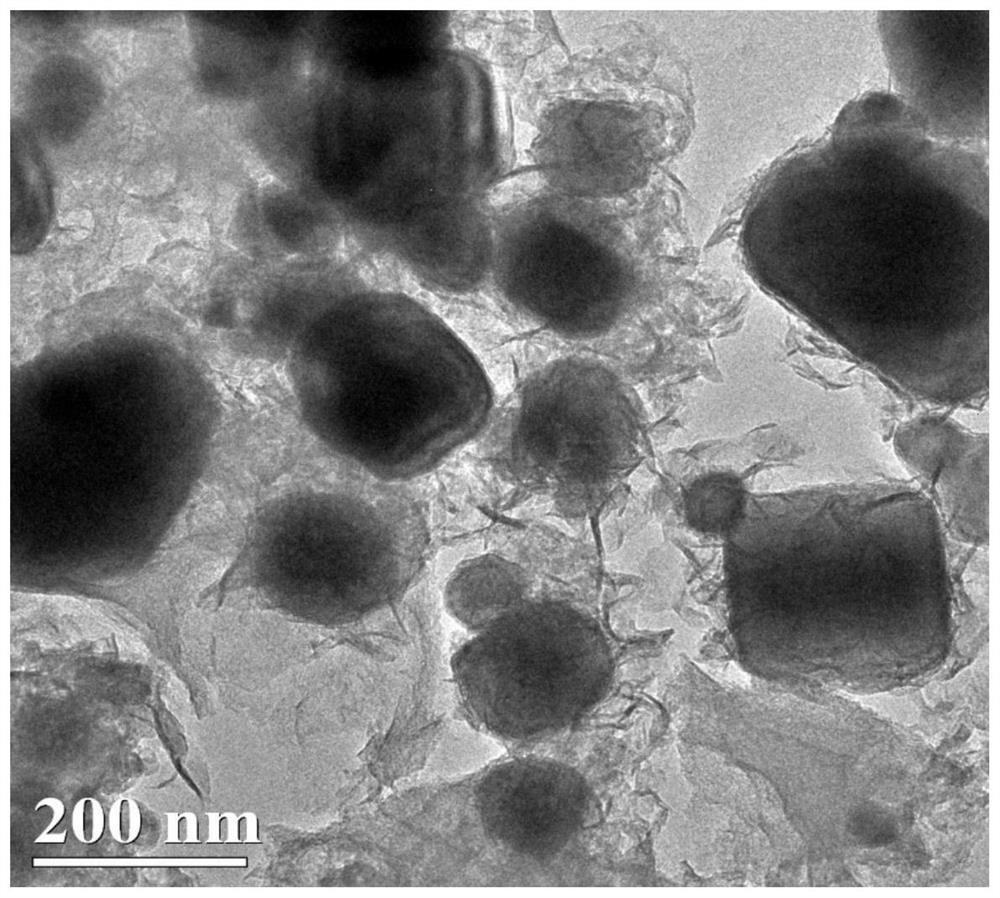

[0028] A method for preparing a transition metal-nitrogen co-doped carbon material oxygen reduction / oxygen evolution bifunctional catalyst according to an embodiment of the present invention comprises the following steps:

[0029] mixing cobalt salt, surfactant and deionized water to prepare cobalt salt solution;

[0030] Mix the iron salt aqueous solution with the cobalt salt solution under stirring conditions, and stir for 0.5h to 1.0h to obtain the first mixed solution, wherein the iron salt aqueous solution is potassium ferricyanide aqueous solution;

[0031] Mixing the silver salt aqueous solution with the first mixed solution under stirring conditions, stirring and reacting for 10.0h to 14.0h to obtain the second mixed solution;

[0032] filtering the second mixed solution, washing the filter residue and drying at 70°C to 90°C for 10.0h to 14.0h to obtain a catalyst precursor;

[0033] Calcining the catalyst at 500° C. to 900° C. for 1.0 h to 3.0 h in an inert atmospher...

Embodiment 1

[0047] Dissolve 0.01mol of cobalt nitrate and 0.05mol of surfactant in deionized water to 1000mL to obtain a cobalt salt solution; dissolve 0.01mol of potassium ferricyanide to 1000mL in deionized water to obtain an iron salt Aqueous solution: Dissolve 0.01 mol of silver nitrate in deionized water to a volume of 1000 mL to obtain a silver salt solution.

[0048] Under the condition of magnetic stirring, add 70mL of iron salt solution dropwise to 100mL of cobalt salt solution, continue to stir for 45min, then add 10mL of silver salt solution dropwise to the above mixture under stirring, continue to stir for 12h , filtered, and the resulting filter residue was washed with ethanol and deionized water in sequence, and dried at 80° C. for 12 hours to obtain a catalyst precursor.

[0049] Grind the catalyst precursor into powder, take a certain amount of catalyst precursor and put it in a porcelain boat in a tube furnace, raise the temperature to 700°C at 5.0°C / min in an inert gas a...

Embodiment 2

[0051] Dissolve 0.01mol of cobalt nitrate and 0.01mol of surfactant in deionized water to 1000mL to obtain a cobalt salt solution; dissolve 0.01mol of potassium ferricyanide to 1000mL in deionized water to obtain an iron salt Aqueous solution: Dissolve 0.01 mol of silver nitrate in deionized water to a volume of 1000 mL to obtain a silver salt solution.

[0052] Under the condition of magnetic stirring, add 70mL of iron salt solution dropwise to 100mL of cobalt salt solution, continue to stir for 45min, then add 10mL of silver salt solution dropwise to the above mixture under stirring, continue to stir for 12h , filtered, and the resulting filter residue was washed with ethanol and deionized water in sequence, and dried at 80° C. for 12 hours to obtain a catalyst precursor.

[0053] Grind the catalyst precursor into powder, take a certain amount of catalyst precursor and put it in a porcelain boat in a tube furnace, raise the temperature to 500°C at 0.5°C / min in an inert gas a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com