Production process of bacteriostatic alginate fiber underwear and product thereof

A seaweed fiber and production process technology, applied in underwear, baby underwear, fiber processing and other directions, can solve the problems of easy breeding of bacteria, general warmth retention, poor air permeability, etc. Soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

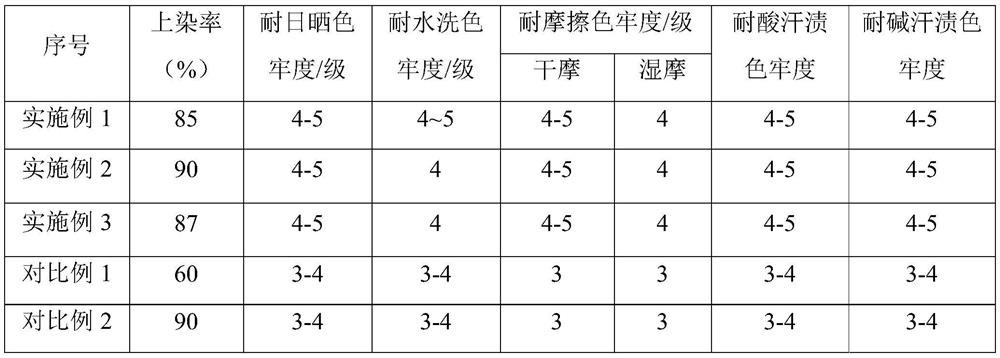

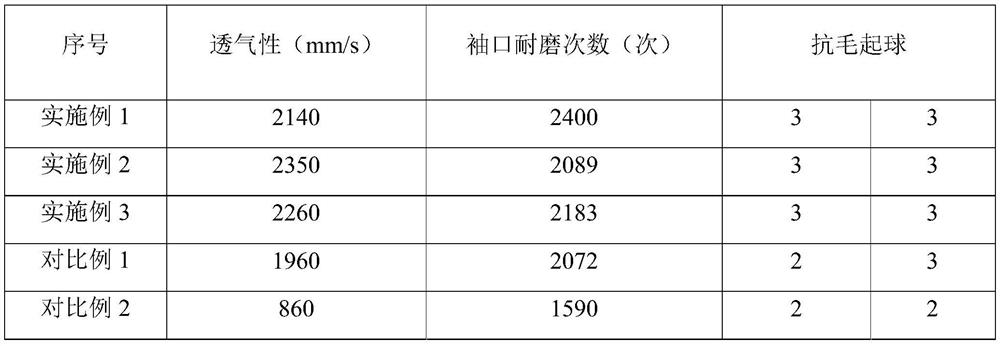

Embodiment 1

[0035] A production process of seaweed fiber antibacterial underwear, comprising the steps of:

[0036] (1) Spinning: select seaweed fiber and colored bamboo fiber of 1.5D*38mm, and blend them with wool, clean them, card, draw, roving, spun yarn, automatic winding and packaging, and the spinning workshop temperature Above 20°C, humidity 60-65%, of which the blending ratio of seaweed fiber, wool and colored bamboo fiber is 10%, 5%, 85%, and spun into 40 blended seaweed colored yarns;

[0037] The wool is a modified wool fiber, and the specific modification process is:

[0038] Screen the clean wool raw materials with an average length of more than 20mm and a short wool rate of less than 35%, open and mix them evenly with a wool machine, add a softener with a weight of 3-5% of the wool raw material, and soften at a temperature of 45-60°C for 2-4 hours. obtaining softened wool; adding surfactant and graphene with 5-10% of wool raw material mass respectively to the softened wool,...

Embodiment 2

[0049] Same as in Example 1, change the proportion of ingredients in 40 blended seaweed colored yarns, the content of seaweed fiber is 30%, the content of wool fiber is 10%, and the content of colored bamboo fiber is 60%.

Embodiment 3

[0051] Same as in Example 1, change the proportion of ingredients in 40 blended seaweed colored yarns, the content of seaweed fiber is 20%, the content of wool fiber is 5%, and the content of colored bamboo fiber is 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com