Hydrogen peroxide tail gas purification aromatic hydrocarbon recovery and expansion power generation method

A tail gas purification and expansion power generation technology, which is applied to chemical instruments and methods, separation methods, liquid hydrocarbon mixture recovery, etc., can solve the problems of complex devices, blockage of heavy aromatics crystallization, damage to equipment, etc., and achieve the goal of reducing investment and simplifying the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

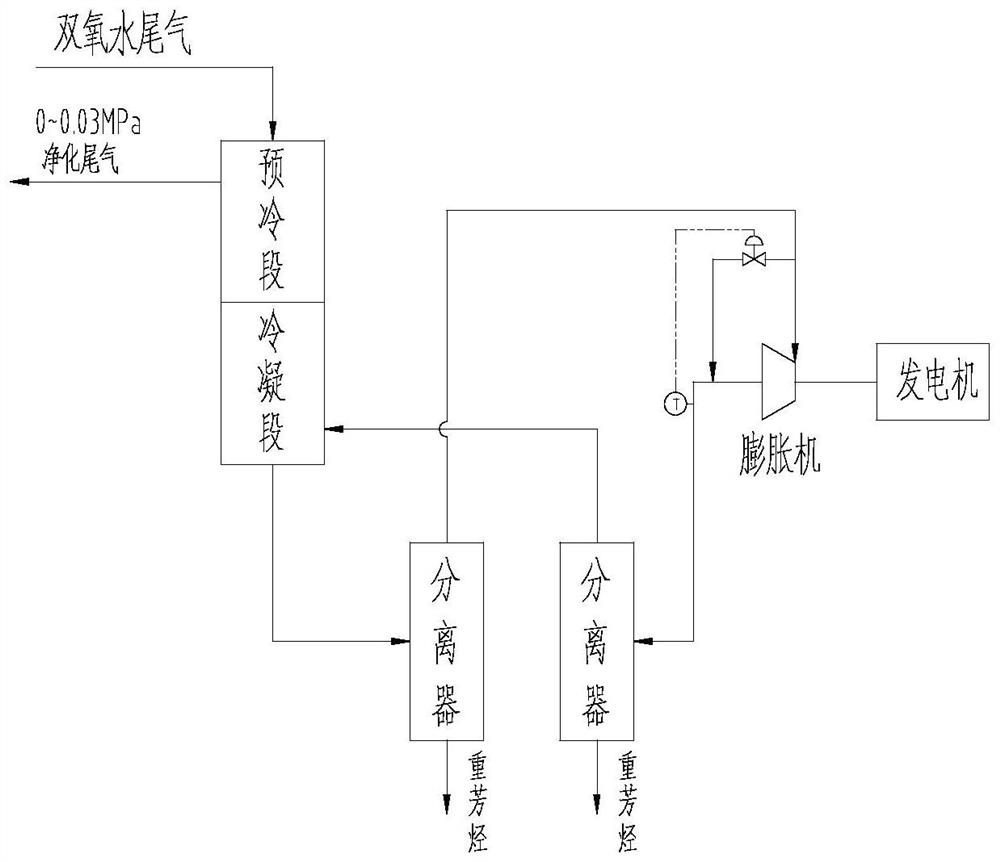

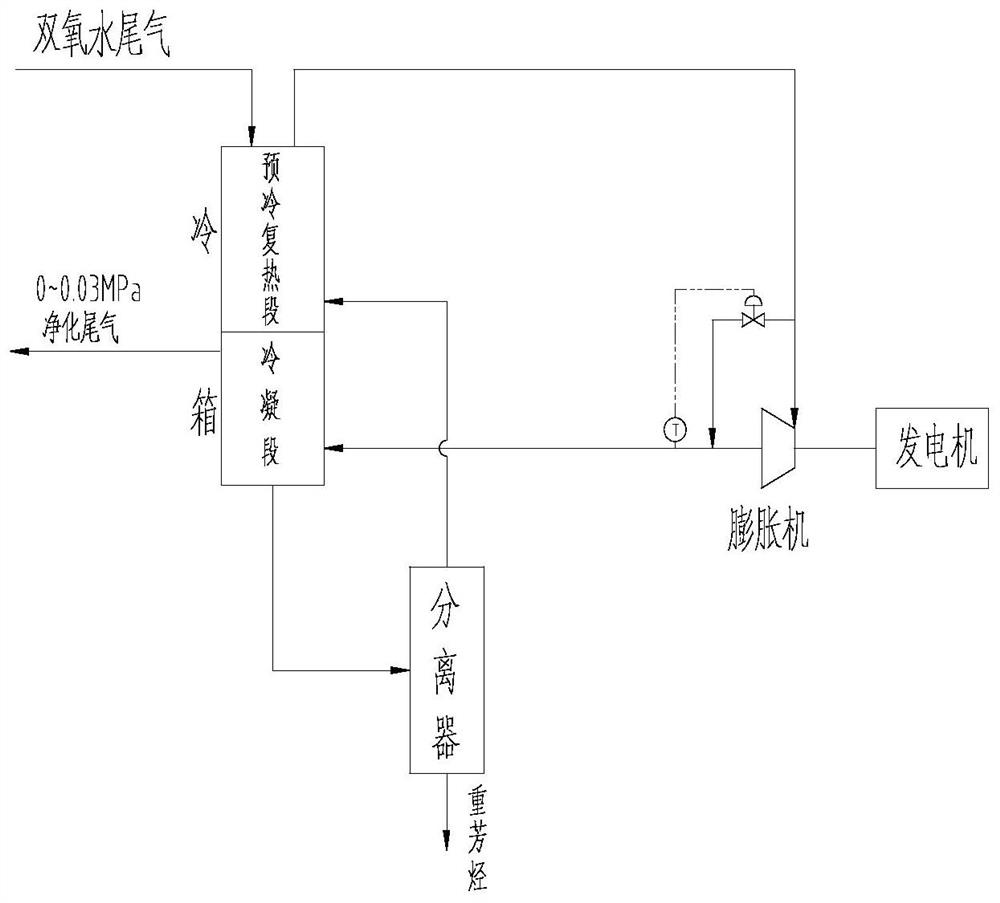

[0022] like figure 2 As shown, the cold box is divided into two parts, the pre-cooling and reheating section and the condensation section, with a total of six outer pipe connections, of which the pre-cooling and reheating section and the condensation section each have three pipe connections. The precooling and reheating section is respectively connected to the hydrogen peroxide tail gas pipe interface (connected to the hydrogen peroxide water tail gas pipe from the hydrogen peroxide production system), connected to the air pipe interface of the separator (connected to the gas outlet pipe of the separator), and connected to the inlet pipe interface of the expander (connected to the expansion The condensing section is respectively connected to the interface of the separator pipe (connected to the inlet pipe of the separator), the interface of the outlet pipe of the expander (connected to the outlet pipe of the expander), and the interface of the hydrogen peroxide tail gas discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com