Integrated optical fiber type photoacoustic probe capable of realizing lateral ultrasonic excitation and detection

A technology of ultrasonic excitation and photoacoustic probe, which is applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problem of weak photoacoustic effect and achieve the effect of reducing weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

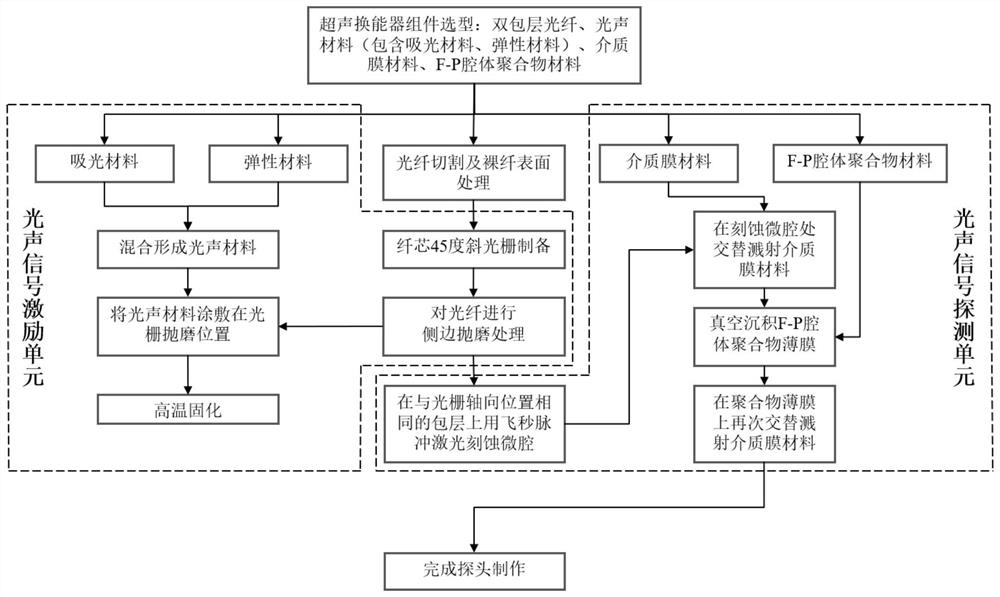

Method used

Image

Examples

Embodiment 1

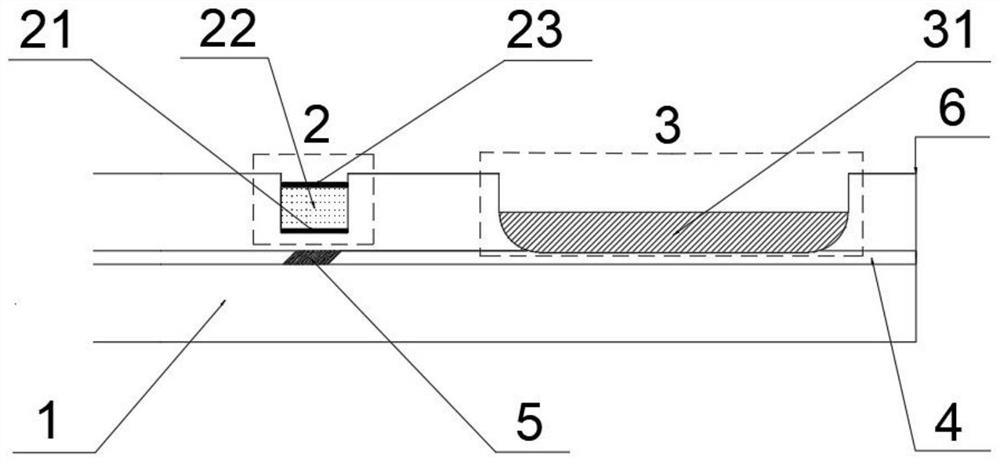

[0041] Embodiment 1, a group of typical components of fiber optic ultrasonic probes and their structural dimensions:

[0042] The model of the optical fiber (1) is Liekki passive 10 / 125DC optical fiber, the outer diameter of the cladding is 125 μm, and the diameter of the core is 10 μm.

[0043] The etched microcavity at the photoacoustic signal detection unit (2) has a width of 30 μm and a depth of 45 μm; the thickness of the F-P cavity structure is about 41.64 μm, the thickness of the dielectric mirrors (21) and (23) are both 1.82 μm, and the polymer film (22) The thickness is 38 μm, wherein the materials of the dielectric mirrors (21) and (23) are zinc sulfide and sodium hexafluoroaluminate, and an eight-layer structure is formed by alternate sputtering; the material of the F-P cavity polymer film (22) It is C-type parylene.

[0044] The polishing length of the photoacoustic signal excitation unit (3) is 10 mm, and the polishing depth is 59 μm; the photoacoustic material (...

Embodiment 2

[0047] Embodiment 2, a group of typical components of fiber optic ultrasonic probes and their structural dimensions:

[0048] The model of the optical fiber (1) is Liekki passive 10 / 125DC optical fiber, the outer diameter of the cladding is 125 μm, and the diameter of the core is 10 μm.

[0049] The etched microcavity at the photoacoustic signal detection unit (2) has a width of 30 μm and a depth of 45 μm; the thickness of the F-P structure is about 41.5 μm, the thickness of the dielectric mirrors (21) and (23) are both 1.75 μm, and the polymer film ( 22) The thickness is 38 μm, wherein the materials of the dielectric mirrors (21) and (23) are magnesium fluoride and zinc selenide, and an eight-layer structure is formed by alternate sputtering; the material of the F-P cavity polymer film (22) is poly Polyethylene terephthalate (PET) or UV-curable optical glue.

[0050] The polishing length of the photoacoustic signal excitation unit (3) is 10 mm, and the polishing depth is 59 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com