Production process of green organic lotus leaf tea rich in nuciferine

A production process and lotus leaf tea technology are applied in the production process field of green organic lotus leaf tea, can solve the problems of poor taste, low leaching rate of lotus leaf base, bitter taste of lotus leaf tea, etc., and achieve the effect of improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

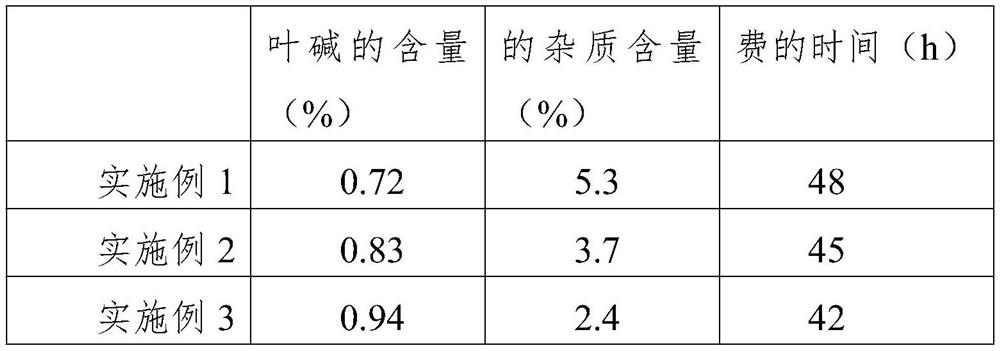

Embodiment 1

[0028] A kind of preparation technology of the green organic lotus leaf tea that is rich in abundant nuciferine of this embodiment comprises the following steps:

[0029] Step 1: Pick out the young leaves from the lotus leaves, wash them repeatedly with clean water to remove the soil on the surface, and then use a blade to pull out the green silk of the lotus leaves, and then slice the lotus leaves;

[0030] Step 2: Put the treated lotus leaves under the blower, and dry the lotus leaves by low-temperature wind. During the drying process, it is necessary to repeatedly turn over the flake lotus leaves to improve the drying efficiency;

[0031] Step 3: Pour the dried lotus leaves into the kneading machine, and at the same time pour iron sand, and knead together with the lotus leaves. During the kneading process, add a certain amount of water and heat the lotus leaves. After kneading the lotus leaves, The lotus leaves and iron sand are poured out from the kneading machine;

[003...

Embodiment 2

[0048] A preparation process of green organic lotus leaf tea rich in nuciferine, comprising the following steps:

[0049] Step 1: Pick out the young leaves from the lotus leaves, wash them repeatedly with clean water to remove the soil on the surface, and then use a blade to pull out the green silk of the lotus leaves, and then slice the lotus leaves;

[0050] Step 2: Put the treated lotus leaves under the blower, and dry the lotus leaves by low-temperature wind. During the drying process, it is necessary to repeatedly turn over the flake lotus leaves to improve the drying efficiency;

[0051] Step 3: Pour the dried lotus leaves into the kneading machine, and at the same time pour iron sand, and knead together with the lotus leaves. During the kneading process, add a certain amount of water and heat the lotus leaves. After kneading the lotus leaves, The lotus leaves and iron sand are poured out from the kneading machine;

[0052] Step 4: Put the lotus leaf and iron sand into ...

Embodiment 3

[0068] A preparation process of green organic lotus leaf tea rich in nuciferine, comprising the following steps:

[0069] Step 1: Pick out the young leaves from the lotus leaves, wash them repeatedly with clean water to remove the soil on the surface, and then use a blade to pull out the green silk of the lotus leaves, and then slice the lotus leaves;

[0070] Step 2: Put the treated lotus leaves under the blower, and dry the lotus leaves by low-temperature wind. During the drying process, it is necessary to repeatedly turn over the flake lotus leaves to improve the drying efficiency;

[0071] Step 3: Pour the dried lotus leaves into the kneading machine, and at the same time pour iron sand, and knead together with the lotus leaves. During the kneading process, add a certain amount of water and heat the lotus leaves. After kneading the lotus leaves, The lotus leaves and iron sand are poured out from the kneading machine;

[0072] Step 4: Put the lotus leaf and iron sand into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com