Preparation method of ceramic atomizing core

A technology of atomizing core and ceramics, which is applied in the field of electronic cigarettes, can solve the problems of low strength of ceramics, achieve the effects of improving interface bonding strength, increasing oil absorption rate, and reducing sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

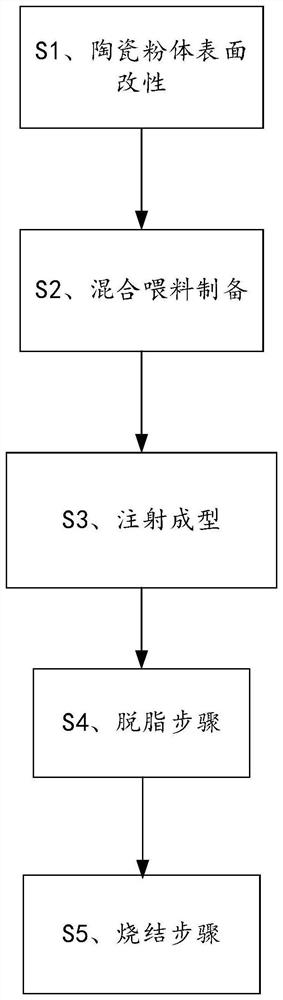

Image

Examples

Embodiment 1

[0028] Embodiment 1: The preparation method of the ceramic atomizing core of this embodiment includes the following steps:

[0029] S1. Surface modification of ceramic powder: natural microporous diatomite or synthetic silica is used as ceramic powder, and the particle size of the ceramic powder is 15 μm. After the ceramic powder is mixed with the surface modifier, ball milling pretreatment is carried out together to form a coating layer on the surface of the ceramic powder, and the surface modified ceramic powder is obtained after drying. The mass ratio of the ceramic powder to the surface modifier is 100:1, and the thickness of the coating layer is 10 nm.

[0030] The surface modifier is composed of at least one of stearic acid, oleic acid, lauryl hydroxystearic acid and citric acid, and in every 100 parts by mass of the ceramic powder, the added surface modifier The number of parts by mass is 1 to 5 parts.

[0031] In this step, the particle size of the ceramic powder is ...

Embodiment 2

[0041] Embodiment 2, the preparation method of the ceramic atomizing core of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0042] S1. Surface modification of ceramic powder: the particle size of the ceramic powder is 30 μm, the mass ratio of the ceramic powder to the surface modifier is 100:5, and the thickness of the coating layer is 20 nm.

[0043] S2. Preparation of mixed feed: the mass ratio of mixed feed to organic glue system is 100:20. The mass ratio of the organic glue system is PW:SA:PE:PP:resin=43:1:32:15:9.

[0044] Mixing steps of the organic rubber system: put PW into a W-type double-roll internal mixer and heat it. After the PW is in a molten state and the temperature of the liquid PW reaches 180°C, add resin, PE and PP respectively, and start the internal mixer. , add SA after banburying for 40min, continue banburying for 3h and end banburying, add slightly positive pressure 250Pa during banburying.

[0045]S3. Injection m...

Embodiment 3

[0049] Embodiment 3, the preparation method of the ceramic atomizing core of this embodiment is basically the same as that of Embodiment 1, the difference is:

[0050] S1. Surface modification of ceramic powder: the particle size of the ceramic powder is 20 μm, the mass ratio of the ceramic powder to the surface modifier is 100:2.5, and the thickness of the coating layer is 15 nm.

[0051] S2. Preparation of mixed feed: the mass ratio of mixed feed to organic glue system is 100:30. The mass ratio of the organic glue system is PW:SA:PE:PP:resin=50:1:25:15:9.

[0052] Mixing steps of the organic rubber system: first put PW into a W-type double-roll mixer and heat it. After the PW is in a molten state and the temperature of the liquid PW reaches 190°C, add resin, PE and PP respectively, and start the mixer. , add SA after banburying for 20min, continue banburying for 3.5h and end banburying, add slightly positive pressure 150Pa during banburying.

[0053] S3. Injection molding:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com