Nitrogen oxide treatment system and treatment method thereof

A technology for nitrogen oxides and treatment systems, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as poor treatment effect and induced deactivation, so as to avoid catalyst poisoning, slow down gas flow rate, and increase reduction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

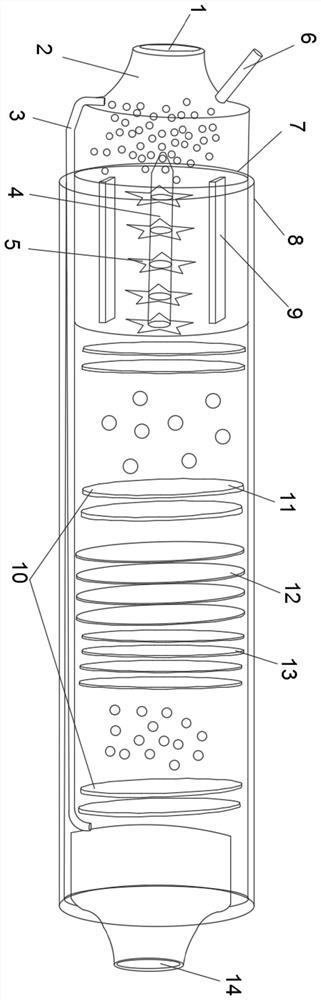

[0037] A preferred embodiment of the present invention provides a nitrogen oxide treatment system, including a gas mixing adjustment area, a plasma excitation area, a SO 2 Absorption zone and NO X Reduction zone, plasma excitation zone, SO 2 Absorption zone and NO X The outer jacket of the reduction area is provided with an insulating and heat-insulating shell 8, and the gas mixing adjustment area is provided with an air inlet 1, and the NO X The reduction zone is provided with an exhaust port 14;

[0038] The gas mixing adjustment area is provided with a gas flow rate adjustment pipe 2 for adjusting the air intake flow rate of the air inlet 1, and the gas mixing adjustment area is also connected with an air intake pipe 6;

[0039] An insulating tube 7 is sleeved in the plasma excitation area, and a discharge copper plate 9 is relatively arranged in the insulating tube 7, and a porous drying plate 10 is detachably arranged behind the area where the insulating tube is locate...

experiment example 1

[0058] Exhaust gas volume is 600Nm 3 / H, the gas composition is: O 2 =18.31kg / H, NOx=231.7kg / H, CO 2 =56.86kg / h, SO 2 =12.35kg / h, the rest is N 2 . The waste gas is passed into the device of the embodiment of the present invention, and treated according to the method of the embodiment, and the NOx in the tail gas at the exhaust port is 4.5g / h.

experiment example 2

[0060] The exhaust gas volume is 580Nm 3 / H, the gas composition is: O 2 =12.55kg / H, NOx=187.6kg / H, CO 2 =44.98kg / h, SO 2 =17.34kg / h, the rest is N 2 . The exhaust gas is passed into the device of the embodiment of the present invention, and treated according to the method of the embodiment, and the NOx in the tail gas at the exhaust port is 3.8g / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com