Manufacturing method of carbon fiber composite material preform for fuel cell hydrogen energy automobile

A fuel cell and composite material technology, applied in the field of fuel cell hydrogen energy vehicles, can solve problems such as limited life, safety and reliability, failure, non-friction damage of brake discs or pads, etc., to improve service life and avoid overheating of accessories Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

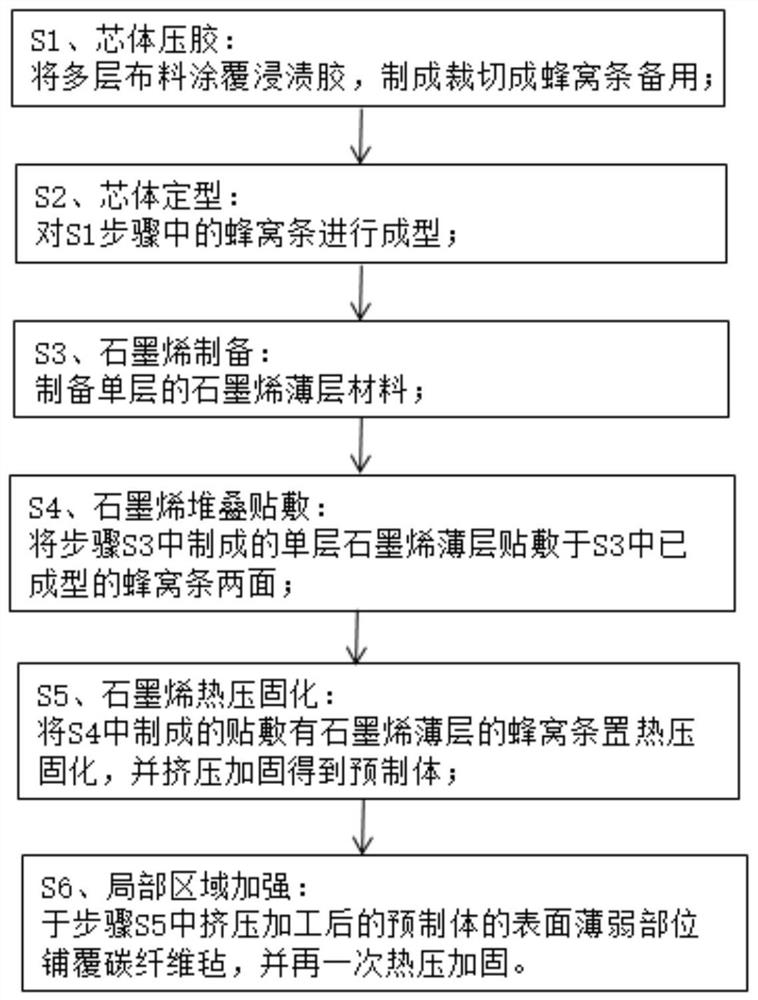

[0027] The invention provides a technical solution: a method for manufacturing a carbon fiber composite material prefabricated body for a fuel cell hydrogen energy vehicle, comprising the following steps:

[0028] S1. Core glueing:

[0029] Coat both sides of the multi-layer fabric with impregnating glue, and shape the multi-layer coated impregnating glue into a wave shape, then stack the multi-layer wave-shaped fabric layer by layer, and make it into a honeycomb plate shape by hot pressing and curing. It is cut into honeycomb strips for use; the cloth is preferably non-dewaxed alkali-free plain weave cloth, and the impregnating glue is preferably epoxy resin glue or polyvinyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com