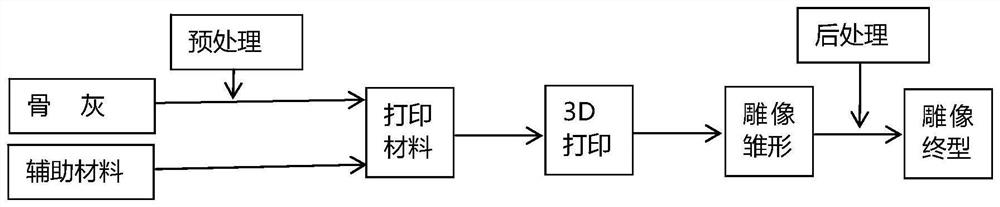

Method for printing bone ash into statue of deceased life before death by using 3D printing process

A 3D printing and craftsmanship technology, which is applied in the fields of decorative art, additive processing, and decorative structures, can solve the problems of low utilization rate of ashes raw materials, waste and loss of ashes raw materials, and increase the occupied area, so as to reduce the overall size of the statue , convenient for offering sacrifices and preservation, and convenient for firing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The pulverized and sieved ashes are uniformly mixed with kaolin to form a powder material, and the proportion of the ashes is 0.1% to 70%. Water-soluble adhesives (such as polyvinyl alcohol, polyacrylamide, carboxymethyl cellulose, sodium alginate, etc.) Further refinement refinement. Mix the corrected slag with unformed powder, add a small amount of printing ink to make the base of the statue, and ensure that the ashes are 100% transferred to the statue.

[0028] After the statue is dried (air-dried or oven-dried), it is put into a furnace to degrease at 100-800°C, and then sintered at 800-1500°C. After cooling down to room temperature, paint, glaze, and sinter at 800-1500°C for the second time.

Embodiment 2

[0030] The treated ashes and paraffin are heated and mixed evenly, and the content of the ashes is 1% to 80%. After cooling, it is pulverized and sieved to make a powder material, which is printed into a statue by a selective sintering printing method (that is, the SLS method). After cleaning, coloring, painting, coating and other processes, it is modified into fine statues. The remaining mixed powder is mixed with the cleaned broken pins, pressed and heated to form a base.

Embodiment 3

[0032] The processed bone ash and ABS plastic powder are mixed and granulated to prepare a thermoplastic wire material with a wire diameter of 0.1-1.0 mm, wherein the bone ash accounts for 1%-30% by weight. Using the FDM method to directly print into statues, the statues can also be decorated into fine statues through finishing, coloring, painting, coating and other processes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com