High-automation connecting line manufacturing assembly line for steel and wood furniture and manufacturing method

An assembly line and furniture technology, applied in the direction of conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of single desktop style and color, low production efficiency, etc., to reduce safety accidents, reduce labor costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

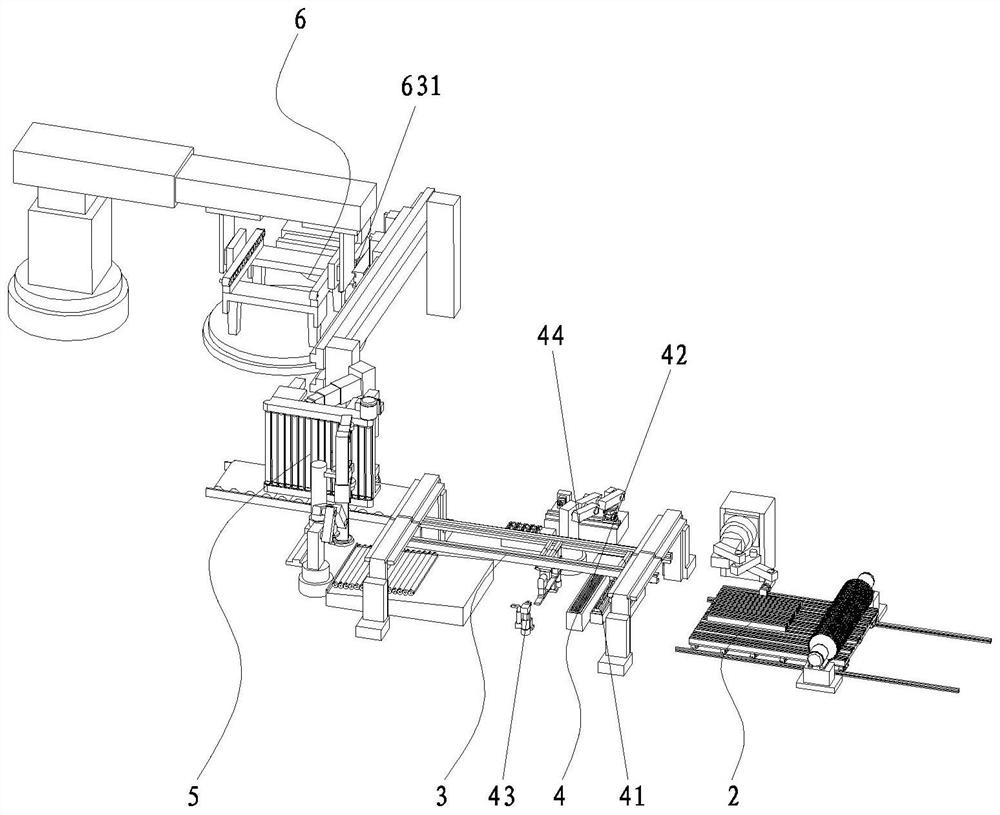

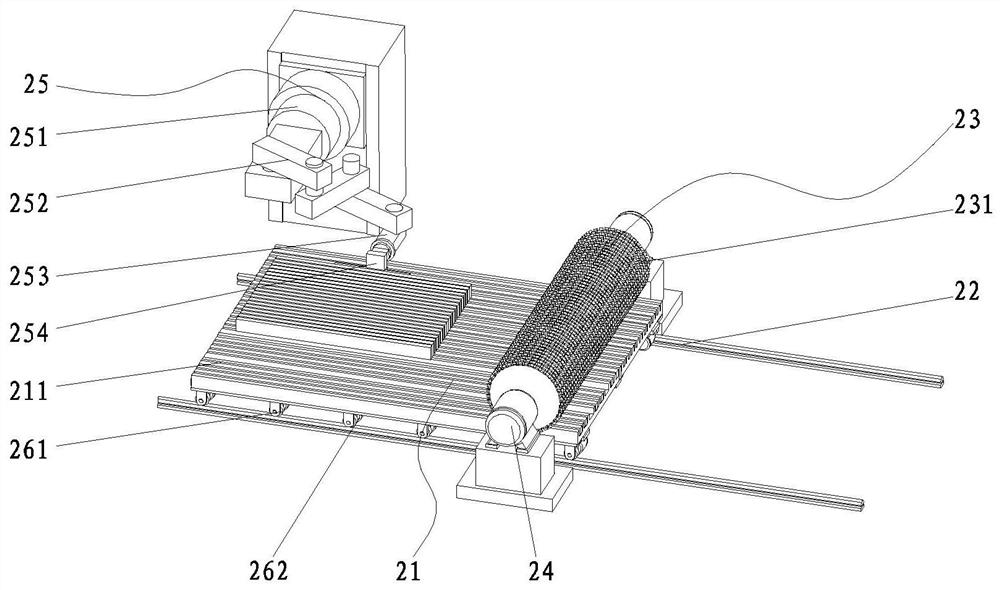

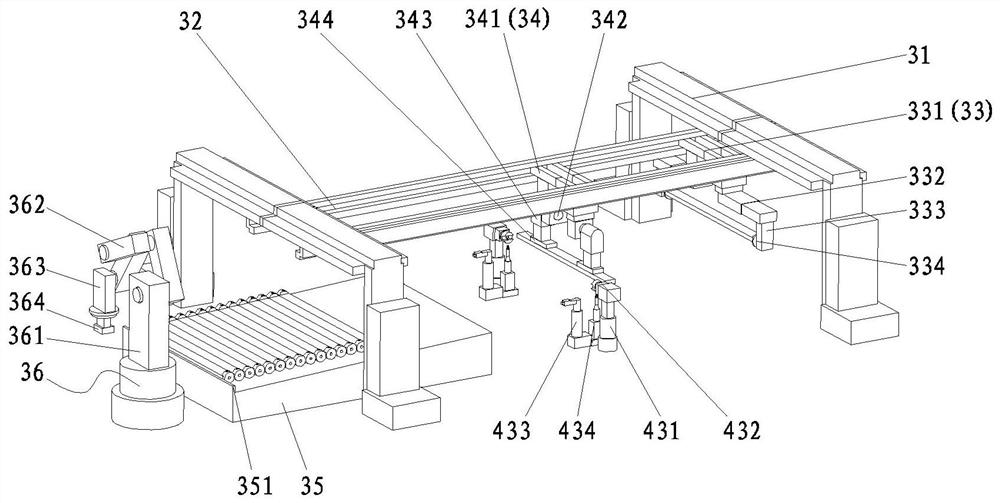

[0053] Such as Figure 1-7 As shown, a highly automated in-line manufacturing line for steel-wood furniture, which includes a cutting device 2 for uniformly cutting wood into planks 11, a plank conveying mechanism 3 for transporting planks 11, and plank processing for spraying and coloring planks 11 Device 4, and the first welding device 5 that welds the connector 12 of the plank 11 on the sprocket 14; the plank conveying mechanism 3 is located at the discharge end of the cutting device 2, and the plank processing device 4 is located under the plank conveying mechanism 3 .

[0054] After adopting the above-mentioned structure, the present invention now evenly cuts the wood into planks 11 and a plurality of planks 11, and paints and dries the planks 11, and then sets connectors 12 at both ends of the planks 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com