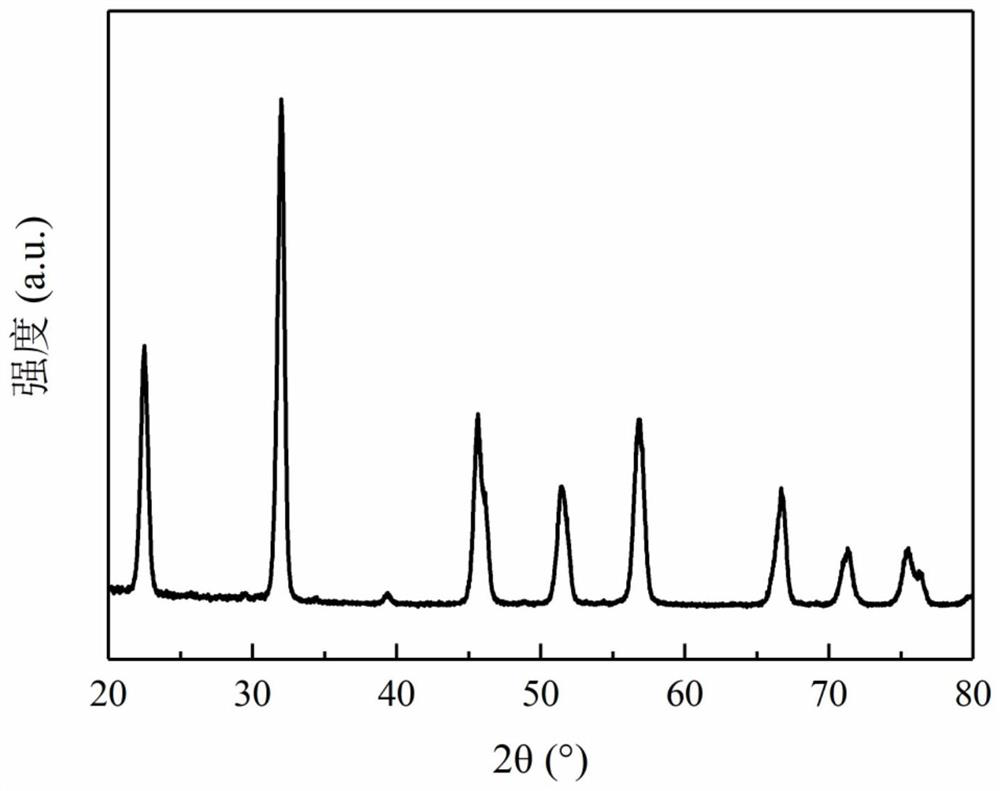

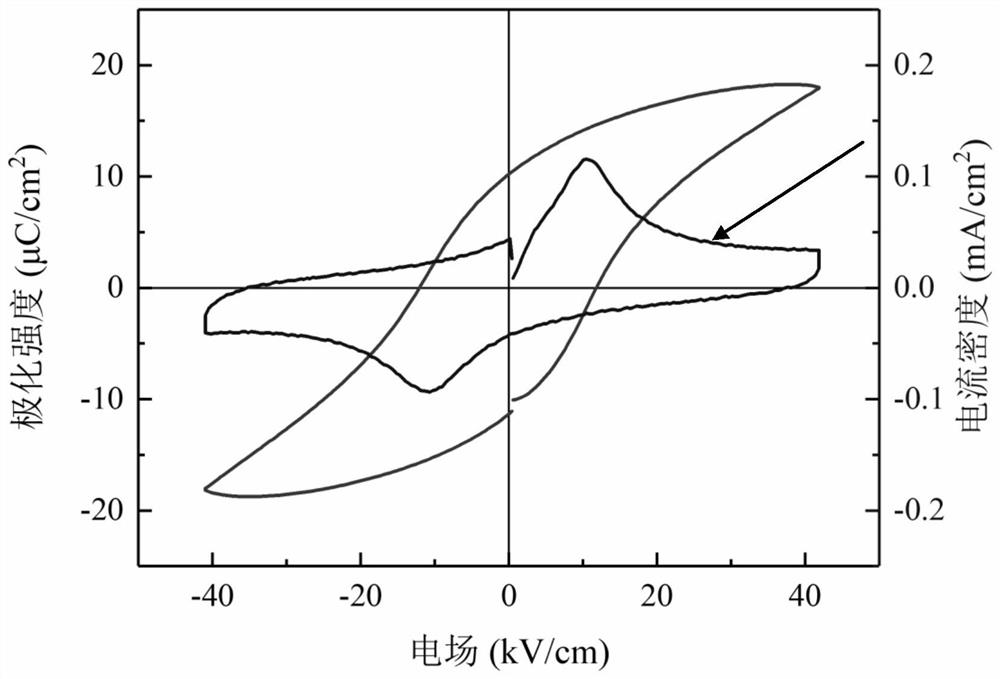

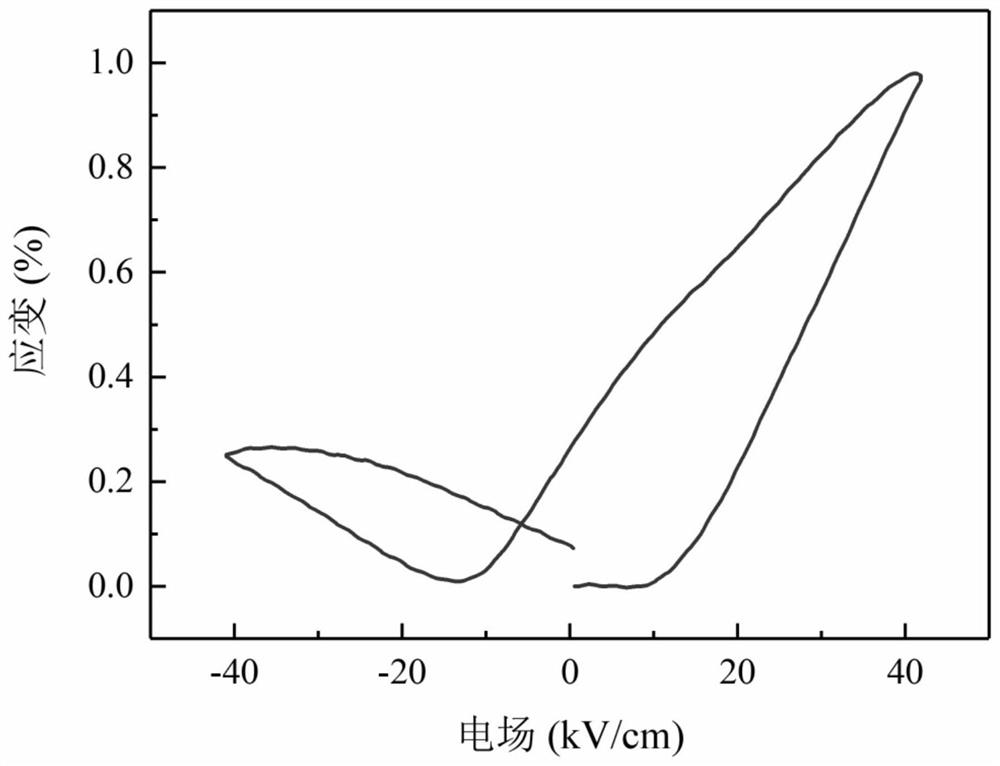

Preparation method of 1.28% large-electrostrictive-strain lead-free potassium sodium niobate-based piezoelectric ceramic

A technology of lead potassium niobate and piezoelectric ceramics, applied in the field of functional materials and piezoelectric ceramics, can solve problems such as switching difficulties, and achieve the effects of rich phase transitions, large piezoelectric activity, and large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 3.433g K according to the raw material ratio of 0.5% mol of lanthanum 2 CO 3 , 2.637g Na 2 CO 3 , 13.234gNb 2 o 5 , 0.163g La 2 o 3 .

[0026] Put the weighed raw material powder into a polytetrafluoroethylene ball mill jar equipped with zirconia balls, and use ethanol as a ball milling aid for ball milling at a rotational speed of 350r / min and a ball milling time of 12-18h.

[0027] The dried powder is sieved and pressed into large pieces with a diameter of 15mm and a height of 28-32mm, placed on a corundum ceramic plate, and calcined at 800-900°C for 2-4h. Secondary ball milling is performed on the once calcined sample, and the ball milling time is 12-18h. After drying and sieving, it is calcined at 800-900°C for 2-4 hours, and then ball milled three times and dried and sieved. The ball milling time is 12-18 hours.

[0028] The powder is pre-pressed into small discs with a diameter of 10mm and a thickness of 0.9-1.1mm, and then formed by a cold isostati...

Embodiment 2

[0034] Weigh 3.45g K2CO3, 2.65g Na2CO3, 13.3g Nb2O5 according to the ratio of raw materials not doped with lanthanum.

[0035] Put the weighed raw material powder into a polytetrafluoroethylene ball mill jar equipped with zirconia balls, and use ethanol as a ball milling aid for ball milling at a rotational speed of 350r / min and a ball milling time of 12-18h.

[0036] The dried powder is sieved and pressed into large pieces with a diameter of 15mm and a height of 28-32mm, placed on a corundum ceramic plate, and calcined at 800-900°C for 2-4h. Secondary ball milling is performed on the once calcined sample, and the ball milling time is 12-18h. After drying and sieving, it is calcined at 800-900°C for 2-4 hours, and then ball milled three times and dried and sieved. The ball milling time is 12-18 hours.

[0037] The powder is pre-pressed into small discs with a diameter of 10mm and a thickness of 0.9-1.1mm, and then formed by a cold isostatic press with a forming pressure of 20...

Embodiment 3

[0041]Weigh 3.416g K2CO3, 2.624g Na2CO3, 13.167g Nb2O5, 0.326g La2O3 according to the raw material ratio of lanthanum doping amount 1%mol.

[0042] Put the weighed raw material powder into a polytetrafluoroethylene ball mill jar equipped with zirconia balls, and use ethanol as a ball milling aid for ball milling at a rotational speed of 350r / min and a ball milling time of 12-18h.

[0043] The dried powder is sieved and pressed into large pieces with a diameter of 15mm and a height of 28-32mm, placed on a corundum ceramic plate, and calcined at 800-900°C for 2-4h. Secondary ball milling is performed on the once calcined sample, and the ball milling time is 12-18h. After drying and sieving, it is calcined at 800-900°C for 2-4 hours, and then ball milled three times and dried and sieved. The ball milling time is 12-18 hours. The powder is pre-pressed into small discs with a diameter of 10mm and a thickness of 0.9-1.1mm, and then formed by a cold isostatic press with a forming pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap