Electrocatalytic oxygen evolution material with fusiform structure as well as preparation method and application of electrocatalytic oxygen evolution material

A technology of electrocatalysis and oxygen evolution, applied in electrolytic organic material coating, electrolytic inorganic material coating, structural parts, etc. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a first aspect, the present invention provides a method for preparing an electrocatalytic oxygen evolution material with a shuttle structure, comprising the following steps:

[0028] Pretreatment of graphite flakes by immersion in strong acid;

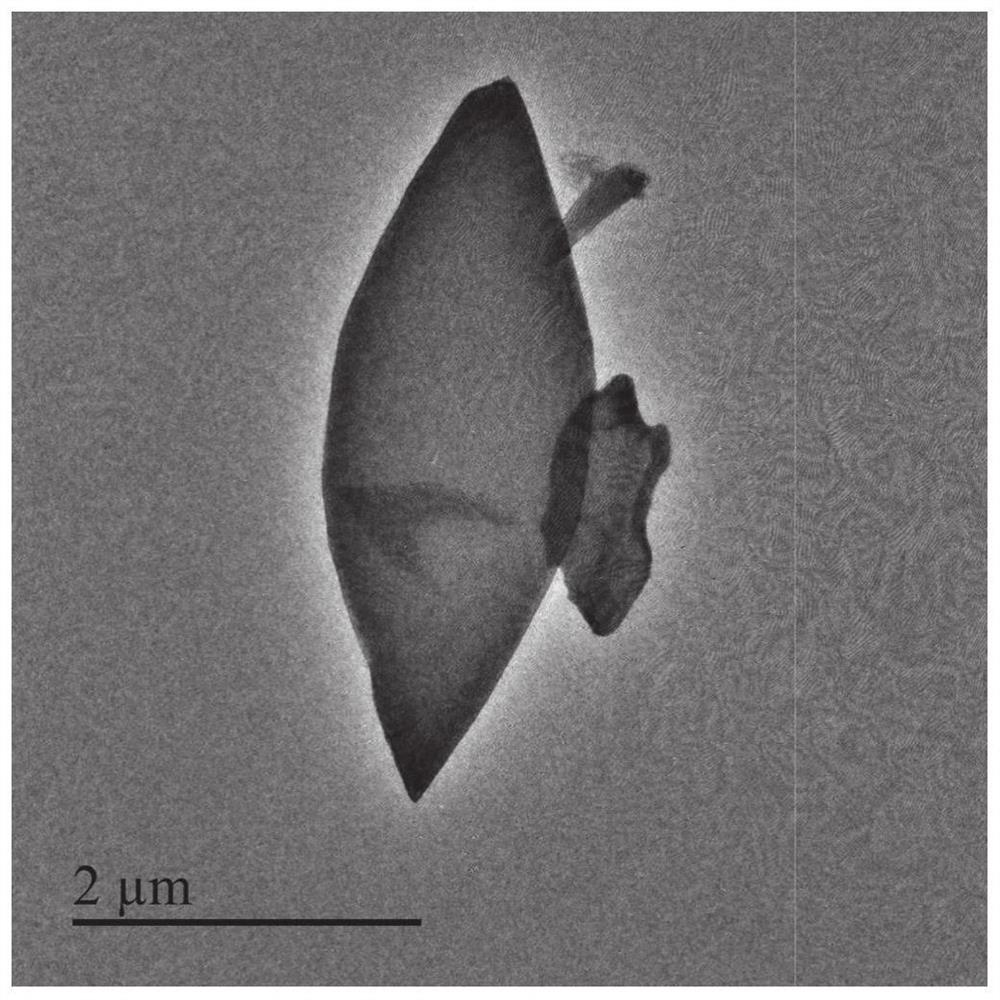

[0029] The pretreated graphite sheet was used as the working electrode to build a three-electrode system for electrodeposition, and the electrodeposition solution was CoCl 2 And the mixed solution of dimethylimidazole, must deposit the graphite flake that micron plate is arranged;

[0030] The graphite sheet deposited with the micron sheet is calcined at high temperature to obtain the electrocatalytic oxygen evolution material.

[0031] In some embodiments, the strong acid solution is aqua regia.

[0032] Further, the graphite sheet is soaked in aqua regia for 10-14h. Soaking in aqua regia for a long time, combined with ultrasonic cleaning, can not only clean and remove impurities attached to the surface, but also improve ...

Embodiment 1

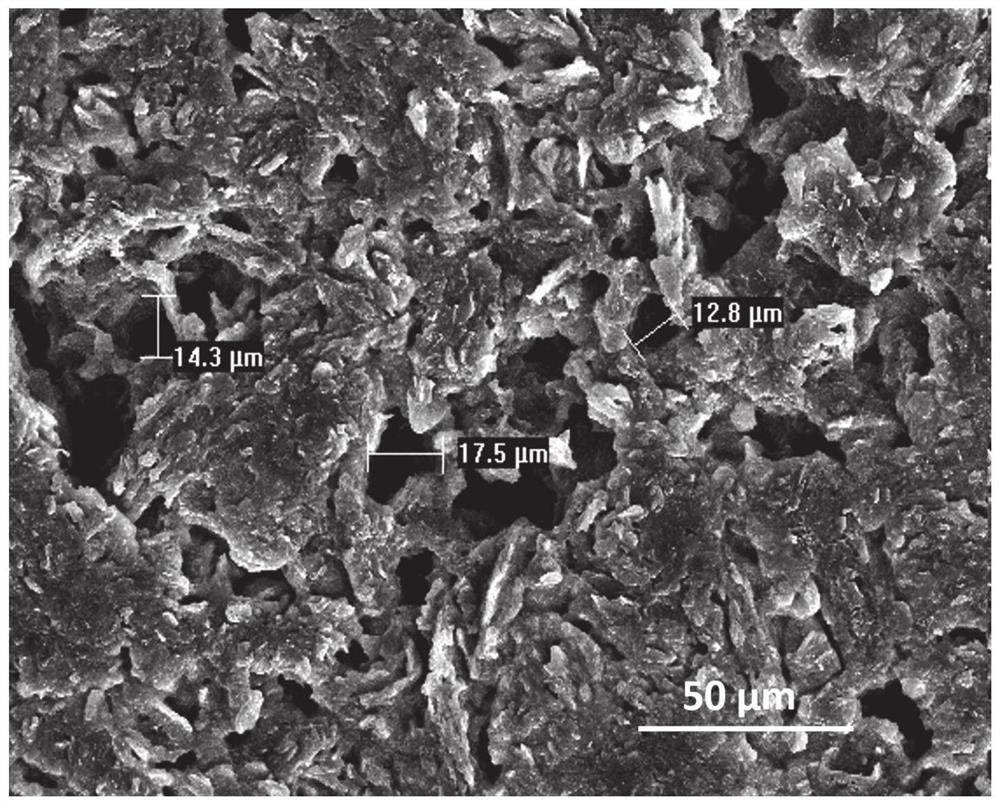

[0046] The graphite flakes (diameter 6mm, thickness 2mm, purity 99.9%) soaked 12 hours with the aqua regia solution of purchase, are neutral to the solution with deionized water cleaning, remove the impurity on the graphite flake surface, improve the hydrophilicity of the graphite flake surface, Add oxygen-containing functional groups. Place the acid-washed graphite sheet in an oven and dry it at 40°C for 12 hours for later use. The microscopic morphology of the graphite sheet surface after pickling treatment obtained by scanning electron microscopy is as follows: figure 1 shown. The surface of the blank graphite sheet presents a loose and irregular structure, which is conducive to the adsorption and deposition of ions.

[0047] A three-electrode system was built, the pretreated blank graphite sheet was fixed on the bottom of the electrode rod with conductive carbon glue as the working electrode, the saturated calomel electrode was used as the reference electrode, and the hi...

Embodiment 2

[0051] The graphite flakes (diameter 6mm, thickness 2mm, purity 99.9%) soaked 12 hours with the aqua regia solution of purchase, are neutral to the solution with deionized water cleaning, remove the impurity on the graphite flake surface, improve the hydrophilicity of the graphite flake surface, Add oxygen-containing functional groups. Place the acid-washed graphite sheet in an oven and dry it at 40°C for 12 hours for later use.

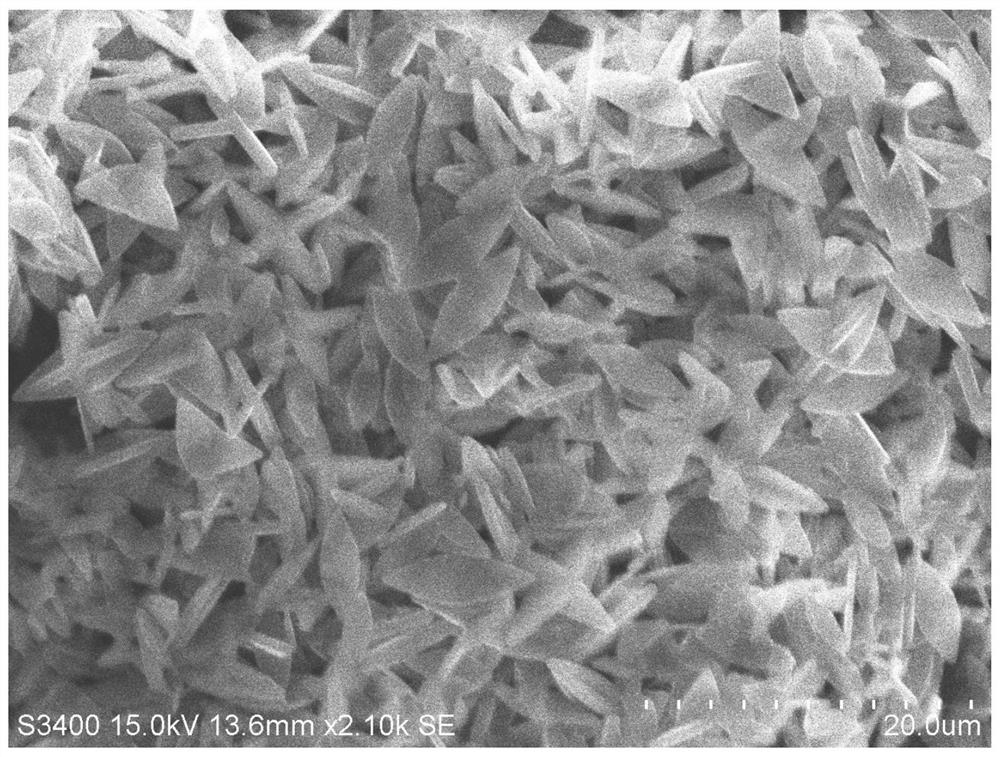

[0052] A three-electrode system was built, the pretreated blank graphite sheet was fixed on the bottom of the electrode rod with conductive carbon glue as the working electrode, the saturated calomel electrode was used as the reference electrode, and the high-purity carbon rod was used as the counter electrode. The electrodeposition solution is 0.6mol / L CoCl 2 , 0.075mol / L dimethylimidazole solution. Using cyclic voltammetry, set the deposition potential to -1.0 to 1.0V (vs. saturated calomel electrode), the scan rate to 50mV / s, and the number of s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com