High-breathability antibacterial anti-mite fabric and preparation process thereof

A preparation process and anti-mite technology, applied in the field of fabrics, can solve the problems of endangering the health of users, poor antibacterial and anti-mite effects, and easy breeding of bacterial mites, etc., to prevent the breeding of mites, durable and efficient antibacterial effect, and protect the body Healthy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A highly air-permeable, antibacterial and anti-mite fabric and its preparation process, including a fabric base layer, the fabric base layer is woven from warp yarns and weft yarns, the warp yarns are blended with cupro fibers and polyester fibers, and the weft yarns are made of antibacterial fibers, modal fibers and Cotton fiber blend.

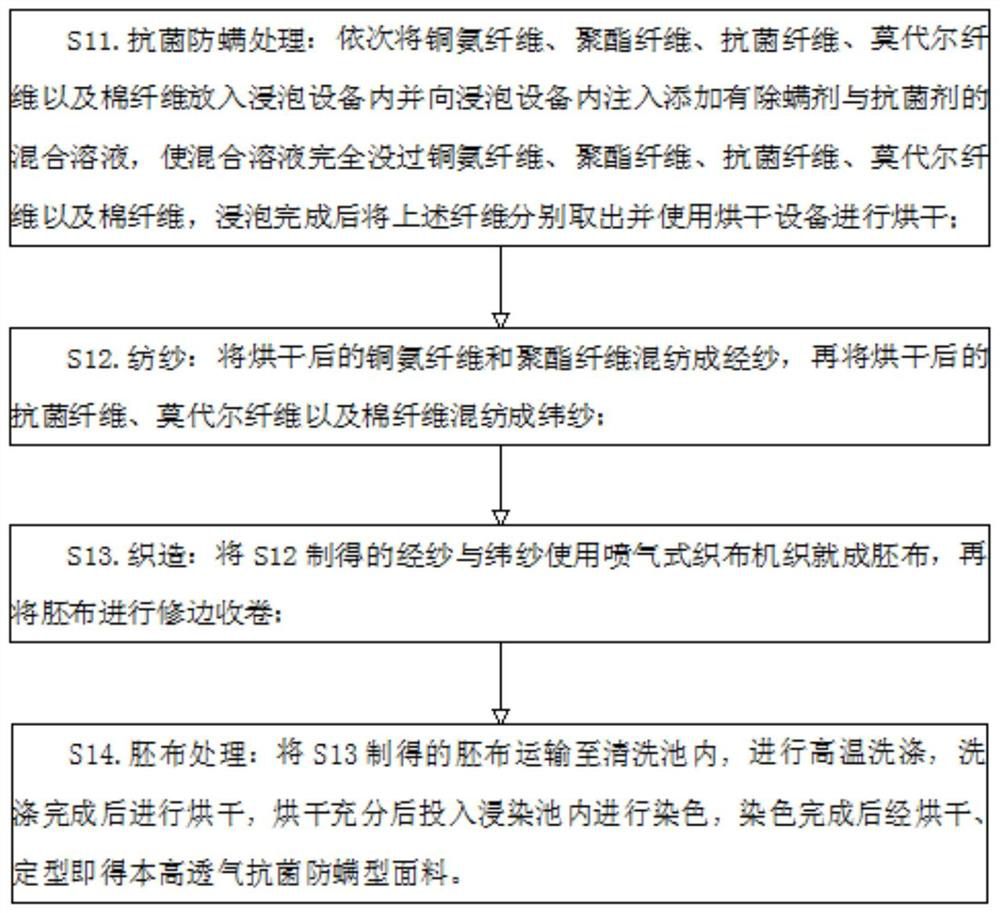

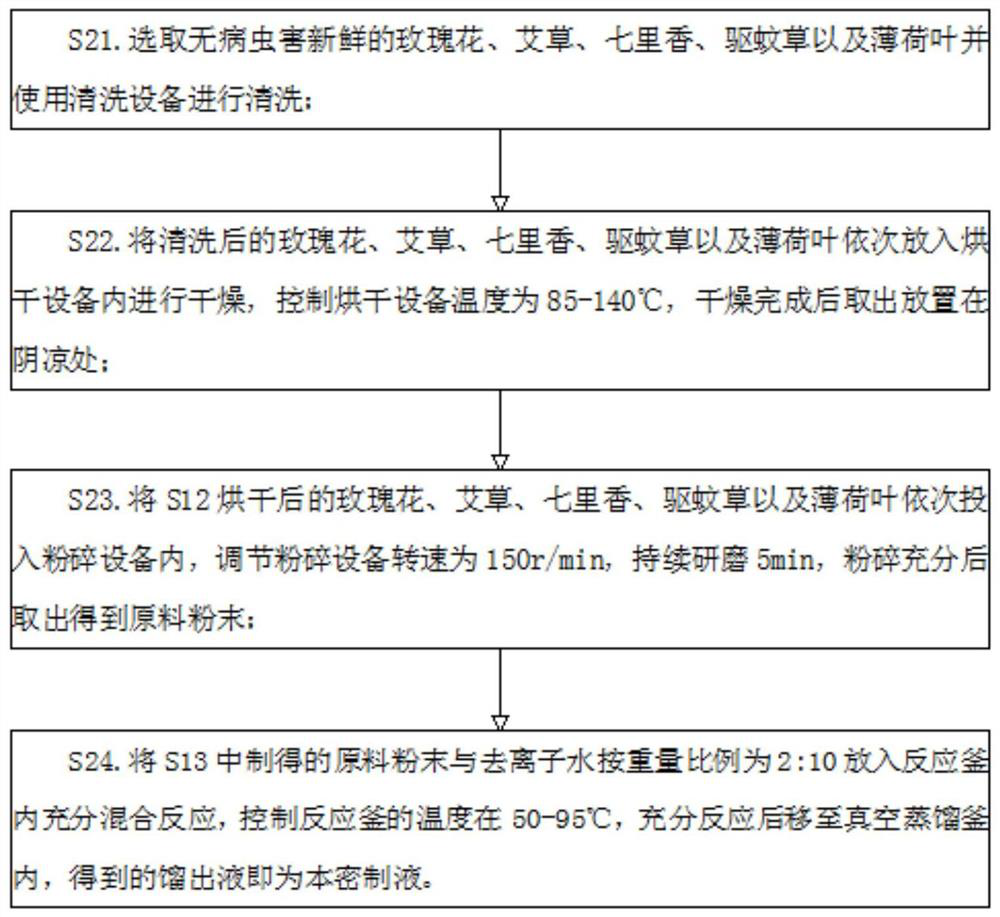

[0032] The present invention also provides a preparation process of a highly breathable, antibacterial and anti-mite fabric, comprising the following steps:

[0033] S11. Antibacterial and anti-mite treatment: Put cupro ammonia fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber into the soaking equipment in turn, and inject the mixed solution added with anti-mite agent and antibacterial agent into the soaking equipment, make the mixing The solution is completely submerged in cupro fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber. After soaking, take out the above fibers and dry them with ...

Embodiment 2

[0052] A highly air-permeable, antibacterial and anti-mite fabric and its preparation process, including a fabric base layer, the fabric base layer is woven from warp yarns and weft yarns, the warp yarns are blended with cupro fibers and polyester fibers, and the weft yarns are made of antibacterial fibers, modal fibers and Cotton fiber blend.

[0053] The present invention also provides a preparation process of a highly breathable, antibacterial and anti-mite fabric, comprising the following steps:

[0054] S11. Antibacterial and anti-mite treatment: Put cupro ammonia fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber into the soaking equipment in turn, and inject the mixed solution added with anti-mite agent and antibacterial agent into the soaking equipment, make the mixing The solution is completely submerged in cupro fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber. After soaking, take out the above fibers and dry them with ...

Embodiment 3

[0073] A highly air-permeable, antibacterial and anti-mite fabric and its preparation process, including a fabric base layer, the fabric base layer is woven from warp yarns and weft yarns, the warp yarns are blended with cupro fibers and polyester fibers, and the weft yarns are made of antibacterial fibers, modal fibers and Cotton fiber blend.

[0074] The present invention also provides a preparation process of a highly breathable, antibacterial and anti-mite fabric, comprising the following steps:

[0075] S11. Antibacterial and anti-mite treatment: Put cupro ammonia fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber into the soaking equipment in turn, and inject the mixed solution added with anti-mite agent and antibacterial agent into the soaking equipment, make the mixing The solution is completely submerged in cupro fiber, polyester fiber, antibacterial fiber, modal fiber and cotton fiber. After soaking, take out the above fibers and dry them with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com