Preparation method of photo-induced heating textile

A textile and light-induced technology, applied in the field of photo-induced heating textiles, can solve the problems of high requirements for heating fibers, long preparation process, complicated process, etc., and achieve the effects of low production cost, wide application range, and increased absorption area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method of preparing a photopolymer textile, a textile is a fiber, a yarn, a woven fabric, a knitted fabric, and a nonwoven fabric. Includes the following steps:

[0040]Preparation of S1, photopolymerized compound powder

[0041] The natural powder was stirred in a mixed solution of the alcohol organic solvent and water, and then the photon heat generating nanom material was added for 30 to 120 min, and the stirring temperature was 25 ~ 90 ° C, and the filtration was taken in sequence, and washed multiple times. Drying treatment at 60 ~ 120 ° C to obtain a photopolymerized compound powder;

[0042] Specifically, the mass ratio of the photoelectric heat generating nanomaterial and the natural powder is 0.15% to 25%, and the natural powder is a wool powder, silk powder, cotton powder and lignin powder. The photoconductive nanomaterial is one or more of graphene, carbon nanotubes, oxide oxide, MXENE, boron nitride, polypyrrole, polyaniline, and polyoxamine. The amount of the...

Embodiment 1

[0053] This embodiment provides a method of preparing a photopolymer textile, and a textile is a polyester yarn, and specifically includes the following steps:

[0054] Preparation of S1, photopolymerized compound powder

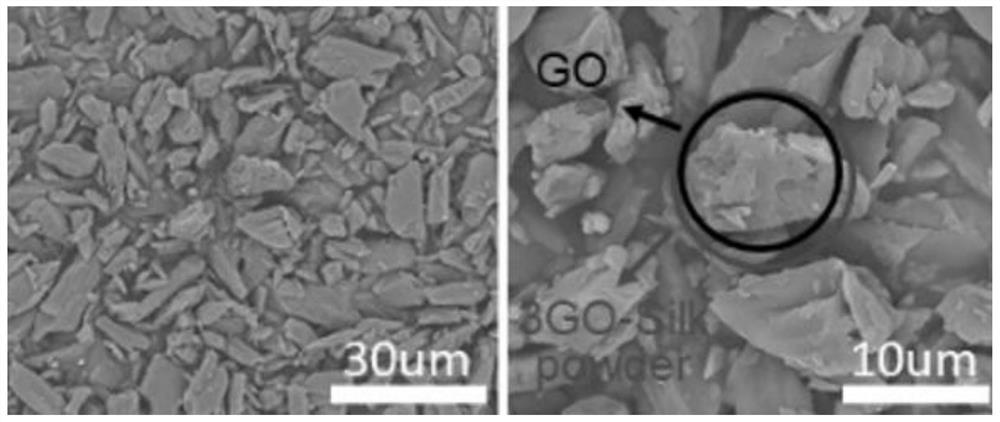

[0055] The silk powder was placed in a mixed solution of ethanol and a water volume ratio of 1: 5, and then the oxide graphene nano material was added for 40 min, the stirring temperature was 60 ° C, filtered, washed multiple times, 90 ° C Dry treatment to obtain a grapy oxide inkylene silk photoreficiency compound powder;

[0056] Among them, the mass ratio (OWF) of the oxide oxide and the silk powder is 3%, and the yolstone oxide inkylene silk photoresist composite powder and the bath ratio of the mixed solution are 1:50.

[0057] Preparation of S2, Photoelectric Slurry

[0058] The chitosan was added to the deionized water to dissolve, then the binder was added to the uniform, and finally the oxide in graphene silk photoresist heat generating compound obtaine...

Embodiment 2

[0070] Example 2 provides a method of preparing a photopolymer textile, compared to Example 1, in which the mass ratio (OWF) of graphene and silk powder in step S1 is 1%, the rest is Example 1 is roughly the same, and details are not described herein.

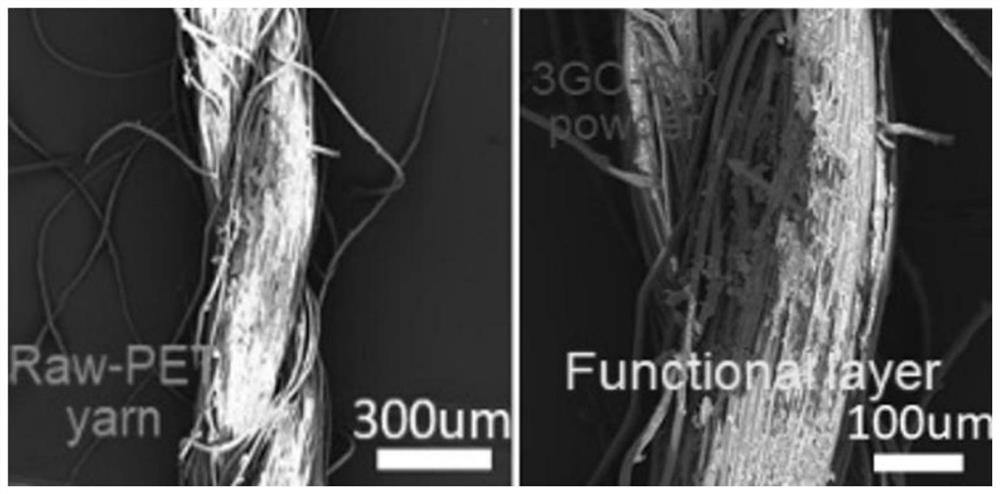

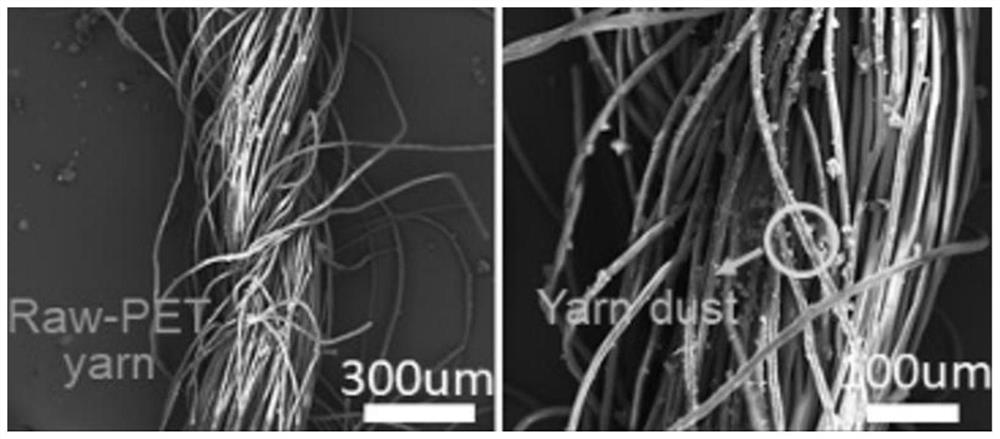

[0071] See Figure 5-6 Distance Figure 5 An electron microscope diagram of the photopolymerized compound prepared for Example 2, Image 6 The photopolymer polyester yarn electron microscopy is prepared. from Figure 5 It can be seen that the composite effect of silk powder and graphene nano material is better; Image 6 The polyester yarn surface load OWF is 1% oxide in graphene silk photoresist heat composite powder, and its load effect is better.

[0072] See Figure 7 Distance Figure 7 A light reflectance result diagram of a 1% oxide oxide silk powder in Example 2 in Example 2 in Example 1. It can be seen that the silk powder has the strongest absorption capacity of the light. From the experiment, although the soil powder has high abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com