Method for building curtain of deeply-buried ultra-thick solution gap fissure aquifer

A curtain and water layer technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of low proportion of effective drilling engineering, small inspection range of borehole inspection, and insufficient flexibility to achieve flexible inspection scope The effect of maneuvering, reducing the difficulty of engineering organization, and improving the interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below with reference to the drawings and embodiments.

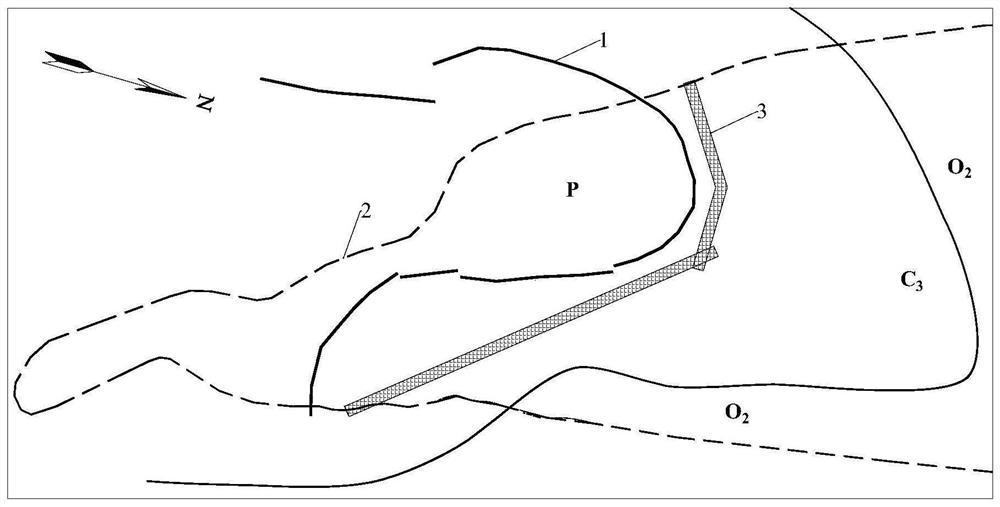

[0047] Project overview: see figure 1 , a coal mine in Anhui Province mainly mines Permian 8 coal 1, and mining area 88 on the north side of the minefield is at the rising end of the syncline. There is a thick and extremely strong water-rich aquifer mainly composed of limestone gravel and breccia in this area. (commonly known as Wuhan), with a buried depth of 220-530m, a thickness of 60-80m, and a karst rate of 8% to 13%. The area delineated by Wuhan boundary 2 in the well field is 2.8km 2. The five-bearing end of the syncline uplift is covered on the strong water-rich aquifer of the Ordovician limestone. The Ordovician limestone has a large hydrodynamic reserve, which directly supplies a large amount of five-bearing, and the fifth-bearing coal is 18 million tons. In the process of mining and production, affected by human disturbance, five-contained water and ash ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com