Super-hydrophilic and super-hydrophobic heat exchange surface combined evaporation heat exchange tube and manufacturing method thereof

A technology of super-hydrophobic surface and heat exchange surface, which is applied in the direction of tubular elements, heat transfer modification, heat exchange equipment, etc., can solve the problems that do not mention the influence of wettability of heat exchange surface and attachments, differences in experimental results, etc., to achieve The effect of delaying the detachment time, reducing the superheat of the wall surface and improving the heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment, further set forth the present application, should be understood that these embodiments are only used to illustrate the present application and are not intended to limit the scope of the present application, after reading the present application, those skilled in the art will understand various aspects of the present application Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

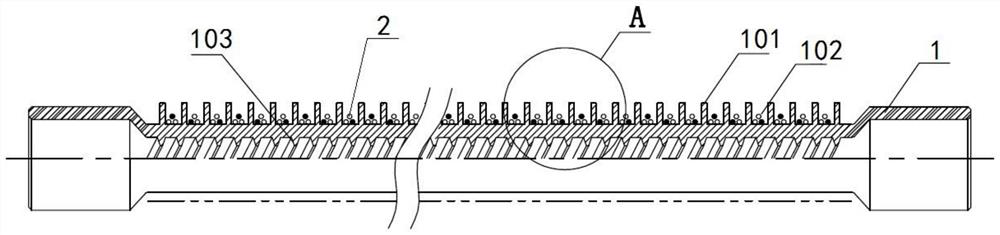

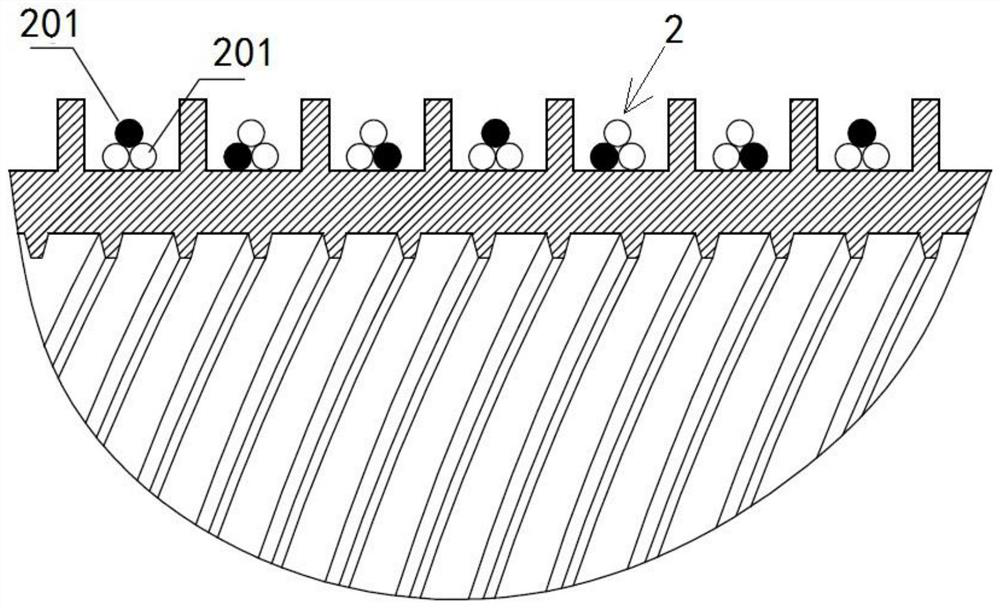

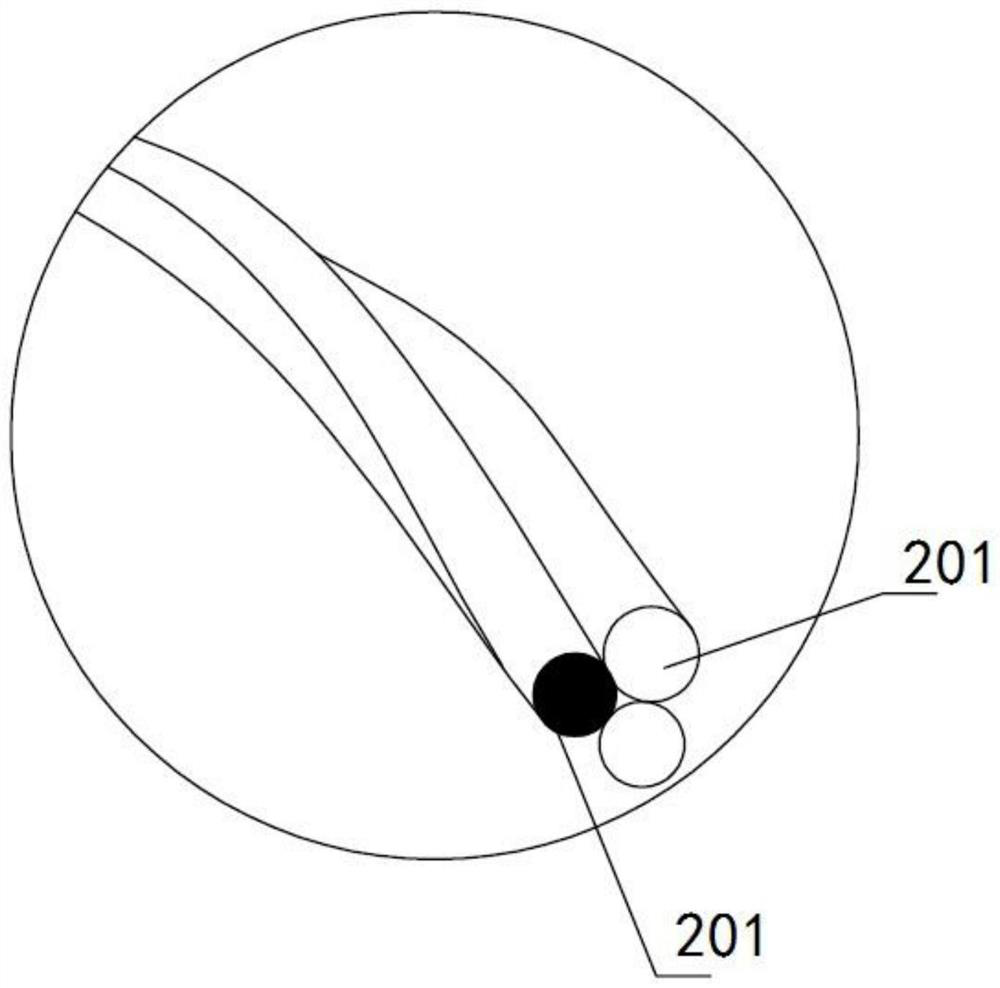

[0029] Figure 1 to Figure 3 It shows a specific embodiment of the superphilic-hydrophobic heat exchange surface combined evaporative heat exchange tube of this application. Like some traditional heat exchange tubes, the heat exchange tube also includes a tube body 1 whose diameter is The outer surface of the tube body 1 is provided with: outer fins 101 extending helically along the length direction of the tube body, formed between the aforementioned outer fins, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com