Flexible porous nanomaterial as well as preparation method and application thereof

A nanomaterial, flexible technology, applied in the fields of electrochemistry and nanomaterials, which can solve the problems of difficulty in obtaining high-quality materials, limiting large-scale applications, high cost and toxicity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a flexible porous nanomaterial, specifically as follows:

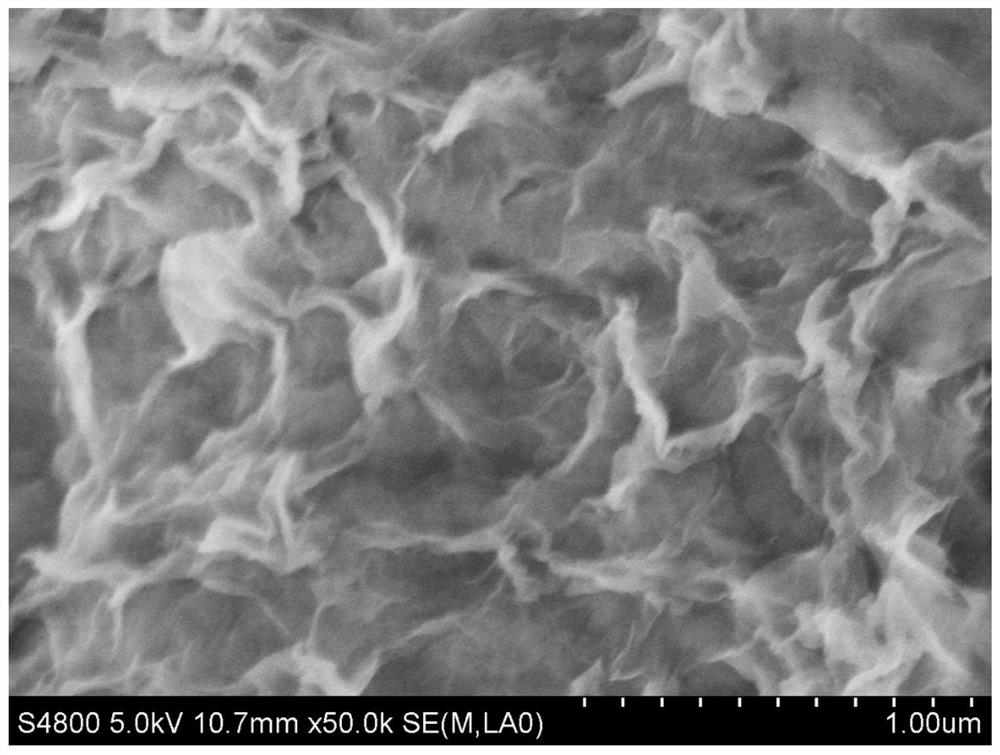

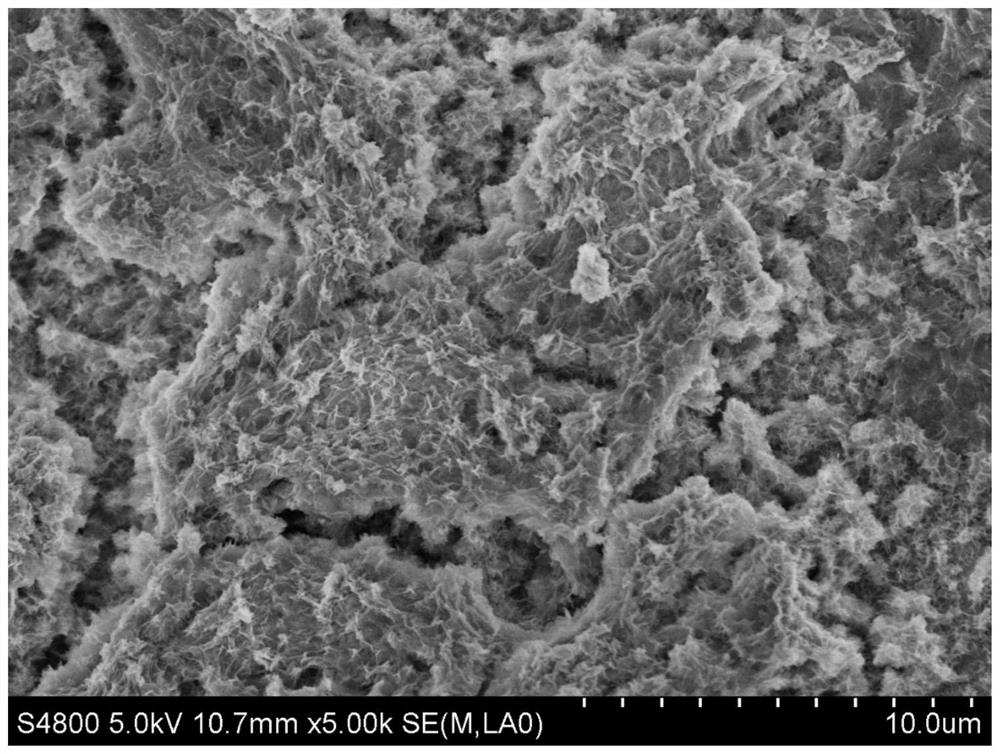

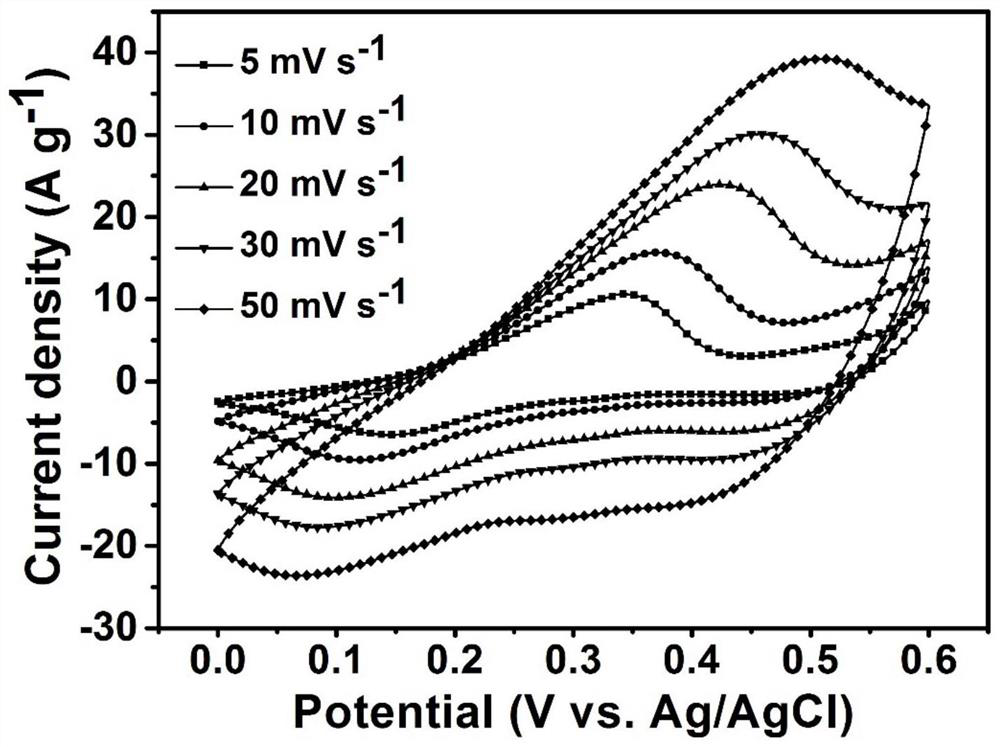

[0035] NiCo 2 o4 The preparation of the porous nanostructure array is synthesized by hydrolysis and solvothermal reaction, and successfully prepared on the CFC support without the addition of conductive agent and binder. First put the clean CFC (flexible carbon fiber) into the solution of nickel sulfate and cobalt sulfate, add urea, react at 90°C for 10 hours, then transfer to a 40ml polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction. Cool at the end of the reaction, centrifuge, wash with deionized water and ethanol several times, dry in a vacuum oven at 60°C, and then calcinate in an air atmosphere at 300-500°C for 2 hours to obtain the core NiCo 2 o 4 / CFC. Then NiCo 2 o 4 / CFC, 1mmol Fe(NO 3 ) 3 9H 2 O, 1 mmol MnCl 2 4H 2 O, 0.2mmol HMT (hexamethylenetetramine), 0.1mmol GS (glucose) were placed in deionized water, stirred at room temperature for ...

Embodiment 2

[0038] A method for preparing a flexible porous nanomaterial, specifically as follows:

[0039] NiCo 2 o 4 The preparation of the porous nanostructure array is synthesized by hydrolysis and solvothermal reaction, and successfully prepared on the CFC support without the addition of conductive agent and binder. First put the clean CFC (flexible carbon fiber) into the solution of nickel sulfate and cobalt sulfate, add urea, react at 90°C for 10 hours, then transfer to a 40ml polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction. Cool at the end of the reaction, centrifuge, wash with deionized water and ethanol several times, dry in a vacuum oven at 60°C, and then calcinate in an air atmosphere at 300-500°C for 2 hours to obtain the core NiCo 2 o 4 / CFC. Then NiCo 2 o 4 / CFC, 3mmol Fe(NO 3 ) 3 9H 2 O, 1 mmol MnCl 2 4H 2 O, 0.5mmol HMT (hexamethylenetetramine), 0.3mmol GS (glucose) were placed in deionized water, stirred at room temperature fo...

Embodiment 3

[0042] A method for preparing a flexible porous nanomaterial, specifically as follows:

[0043] NiCo 2 o 4 The preparation of the porous nanostructure array is synthesized by hydrolysis and solvothermal reaction, and successfully prepared on the CFC support without the addition of conductive agent and binder. First put the clean CFC (flexible carbon fiber) into the solution of nickel sulfate and cobalt sulfate, add urea, react at 90°C for 10 hours, then transfer to a 40ml polytetrafluoroethylene-lined stainless steel autoclave for hydrothermal reaction. Cool at the end of the reaction, centrifuge, wash with deionized water and ethanol several times, dry in a vacuum oven at 60°C, and then calcinate in an air atmosphere at 300-500°C for 2 hours to obtain the core NiCo 2 o 4 / CFC. Then NiCo 2 o 4 / CFC, 10mmol Fe(NO 3 ) 3 9H 2 O, 2 mmol MnCl 2 4H 2 O, 1mmol HMT (hexamethylenetetramine), 0.8mmol GS (glucose) were placed in deionized water, stirred at room temperature for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com