Multi-layer stack type EEBG structure and design method thereof

A structure design and stacking technology, applied in the multi-layer stacked EEBG structure and its design field, can solve the problems of poor high frequency suppression effect, high cost, and only partial bandwidth range applications, and achieve noise reduction and low production cost. , the effect of increased bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

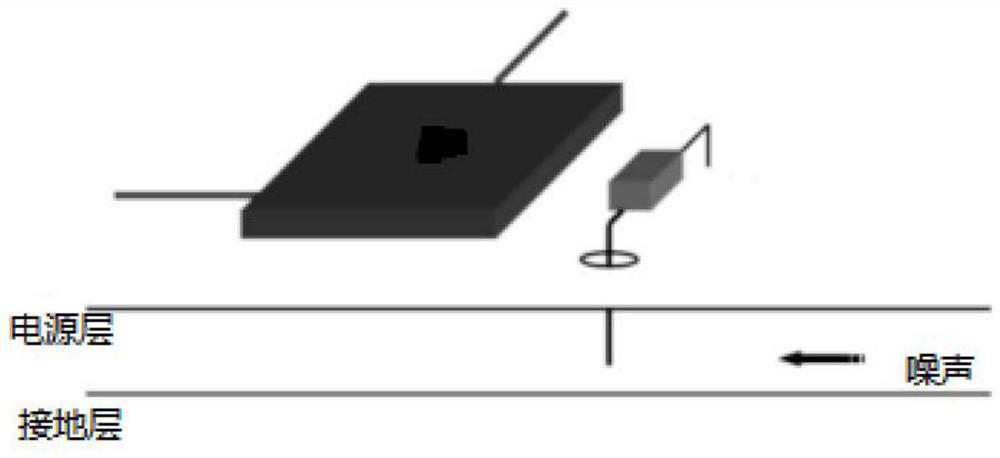

Problems solved by technology

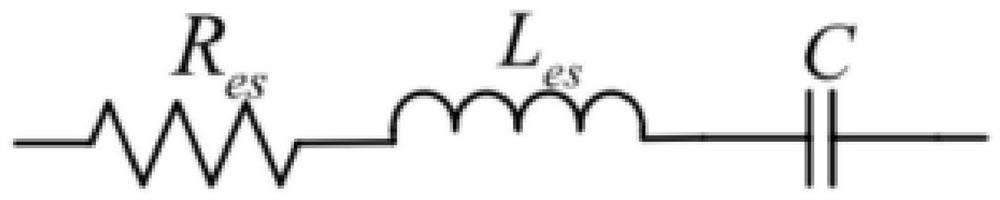

Method used

Image

Examples

Embodiment 1

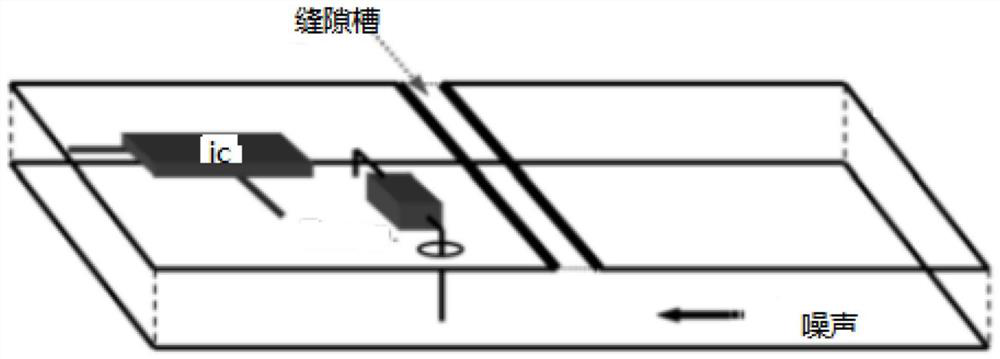

[0054] The embodiment of the present invention also provides a multi-layer stacked EEBG structure, several EEBG structures using two different sizes are arranged and installed in opposite directions, please refer to Figure 6 and Figure 7 , including: twenty unit cells, twenty unit cells are arranged in a matrix, and the unit cells include: the PWR layer of the parallel metal plate, several stacked EEBGs, and the GND layer of the parallel metal plate; the stacked EEBG includes the first EEBG, four a second EEBG; four second EEBGs are also arranged in a matrix;

[0055] The stacked EEBG is installed between the PWR layer and the GND layer of the parallel metal plate;

[0056] The first EEBG is composed of a first square metal sheet and a first connecting column; a number of communication holes are opened on the square sheet; one end of the first connecting column is connected to the square sheet, and the other end is connected to the power layer;

[0057] The first EEBG and ...

Embodiment 2

[0066] The embodiment of the present invention provides a multi-layer stacked EEBG structure design method, please refer to Figure 9 , including the following steps:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com