Mulberry male spica tea and processing method thereof

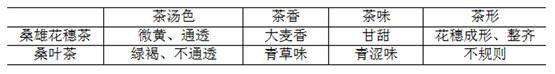

A processing method and mulberry technology, applied in the fields of tea substitutes, food science, food preservation, etc., can solve the problems of undeveloped, difficult to collect mulberry tassel on a large scale, and achieve complete shape, transparent soup color, good nutrition and health care. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A processing method for mulberry tassel tea, comprising steps:

[0032] S1, picking: collect fresh mulberry tassels and remove impurities as raw materials; the fresh mulberry tassels are picked from the mulberry variety that flowers first and then leaves, and is a high yield of first flowers and later leaves and high tassel yield selected by the inventor Tassels of mulberry species. The picking time is 3-5 days. The picking date mentioned varies with the location, temperature and mulberry tree species. Taking Hangzhou, Jiaxing and Huzhou as examples, the picking date is probably in early March.

[0033] S2. Cleaning and drying: spread the raw materials of step S1 in the screen frame with a thickness of 2 cm, and use the method of atomizing and spraying cleaning liquid at 5°C to clean and remove the dust attached to the surface of the raw materials, and then place them in a low temperature and cold wind environment Set aside to dry.

[0034] S3. Dehydration: The raw m...

Embodiment 2

[0041] A processing method for mulberry tassel tea, comprising steps:

[0042] S1, picking: collect fresh mulberry tassels and remove impurities as raw materials; the fresh mulberry tassels are picked from the mulberry variety that flowers first and then leaves, and is a high yield of first flowers and later leaves and high tassel yield selected by the inventor Tassels of mulberry species. The picking time is 3-5 days. The picking date mentioned varies with the location, temperature and mulberry tree species. Taking Hangzhou, Jiaxing and Huzhou as examples, the picking date is probably in early March.

[0043] S2. Cleaning and drying: Spread the raw materials in step S1 in the screen frame with a thickness of 3 cm. Use the method of atomizing and spraying cleaning liquid at 15°C to clean and remove the dust attached to the surface of the raw materials, and then place them in a low temperature and cold wind environment. Set aside to dry.

[0044] S3. Dehydration: The raw mat...

Embodiment 3

[0051] A processing method for mulberry tassel tea, comprising steps:

[0052] S1, picking: collect fresh mulberry tassels and remove impurities as raw materials; the fresh mulberry tassels are picked from the mulberry variety that flowers first and then leaves, and is a high yield of first flowers and later leaves and high tassel yield selected by the inventor Tassels of mulberry species. The picking time is 3-5 days. The picking date mentioned varies with the location, temperature and mulberry tree species. Taking Hangzhou, Jiaxing and Huzhou as examples, the picking date is probably in early March.

[0053] S2. Cleaning and drying: Spread the raw materials in step S1 in the screen frame with a thickness of 2.5 cm. At 18°C, use the method of atomizing and spraying the cleaning solution to clean and remove the dust attached to the surface of the raw materials, and then cool them with cold air at a low temperature. Ambient dry.

[0054] S3. Dehydration: dehydrating the raw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com