Method for preparing cylindrical Al2O3-GdAlO3 binary eutectic ceramic through selective laser melting

A laser melting, binary eutectic technology, applied in the field of ceramic materials, can solve the problems of difficult SLM forming, coarse sintered structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

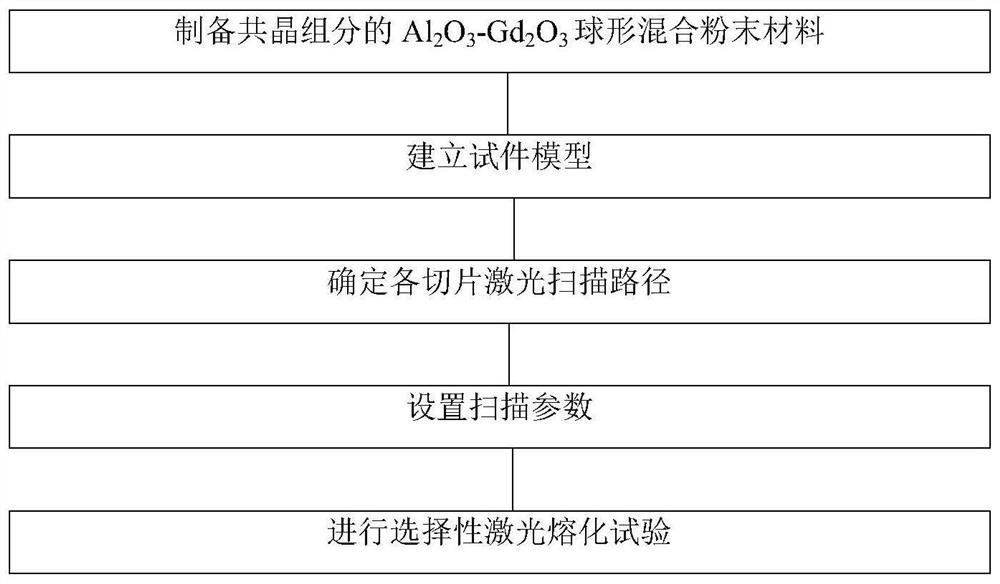

[0069] The invention is a kind of selective laser melting to prepare cylindrical Al 2 o 3 -Gd 2 o 3 The method of binary eutectic ceramics, the specific process is:

[0070] Step 1, prepare Al of eutectic composition 2 o 3 -Gd 2 o 3 Spherical mixed powder material:

[0071] Weigh Al with a total mass of 400g 2 o 3 Powder and Gd 2 o 3 powder; the Al 2 o 3 Powder and Gd 2 o 3 The proportion of powder is eutectic molar ratio Al 2 o 3 :Gd 2 o 3 =77:23.

[0072] Al to be weighed 2 o 3 Powder and Gd 2 o 3 The powders were mixed and alcohol and polyvinyl alcohol solutions were added, and the above mixture was ball milled for 4 hours at a speed of 550 rpm using a ball mill to obtain a mixture. The consumption of described alcohol is described Al 2 o 3 Powder and Gd 2 o 3 10wt.% of the total powder mass, the amount of the polyvinyl alcohol solution is the Al 2 o 3 Powder and Gd 2 o 3 5wt.% of the total powder mass.

[0073] The above mixture is subjecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com