Preparation method of novel ceramsite and application of novel ceramsite in black and odorous water body

A technology of black and odorous water body and ceramsite, which is applied in the application, ceramic products, chemical instruments and methods, etc., can solve the problems of low removal rate of pollutant indicators in water body, poor adsorption effect, insufficient swelling degree, etc. The effect of dissolved oxygen content in water, improving water quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

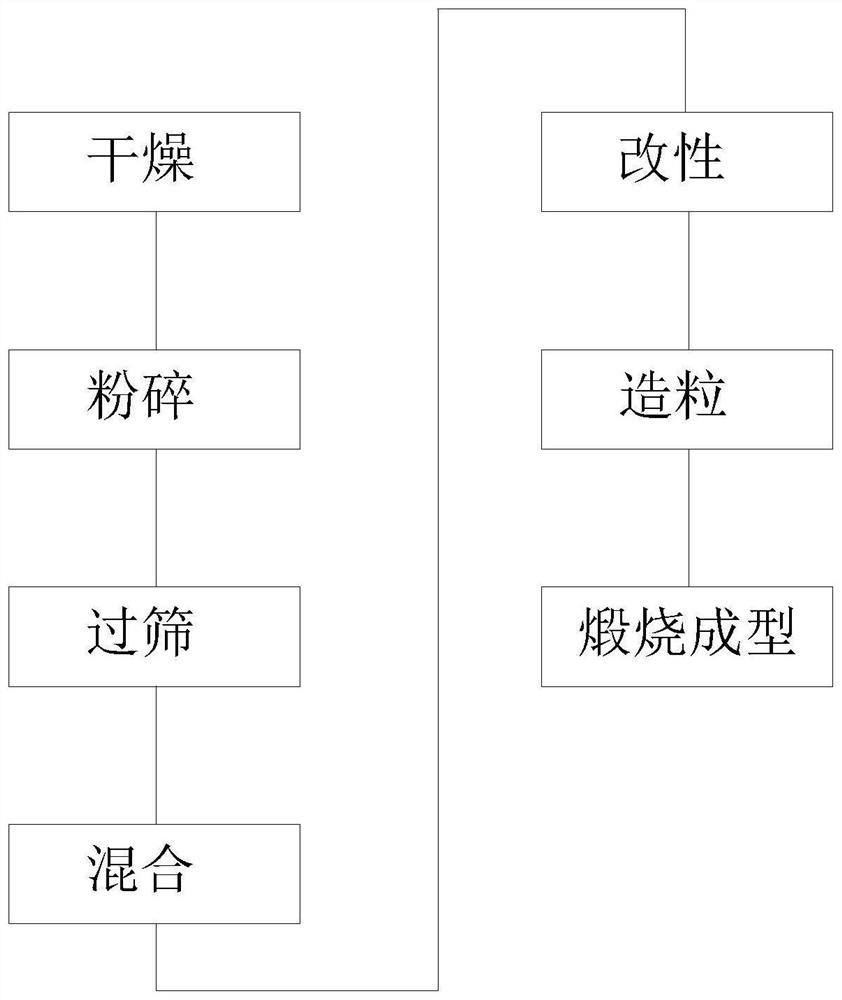

[0042] like figure 1 Shown, the preparation method of a kind of novel ceramsite of the embodiment of the present invention, comprises the steps:

[0043] Step 1: Dry

[0044] The various raw materials for preparing the new ceramsite are transported to the dryer through a conveyor for drying, and dried until the moisture content is not higher than 3%, and then the raw materials are stored in the raw material warehouse for use;

[0045] Step 2: Shred

[0046] The bulk materials in the raw materials for preparing the new ceramsite are transported to the crusher through a conveyor for crushing, and the particle size after crushing is 1 mm; then other small particle materials in the raw materials for preparing the new ceramsite are And the materials crushed by the crusher are respectively put into the resonance mill or ball mill for grinding or ball milling; finally, they enter the winnowing and classifying machine for winnowing. Transported to the storage bin for storage;

[0...

Embodiment 2

[0059] like figure 1 Shown, the preparation method of another kind of novel ceramsite of the embodiment of the present invention, comprises the following steps:

[0060] Step 1: Dry

[0061] The various raw materials for preparing the new ceramsite are transported to the dryer through a conveyor for drying, and dried until the moisture content is not higher than 3%, and then the raw materials are stored in the raw material warehouse for use;

[0062] Step 2: Shred

[0063] The bulk materials in the raw materials for preparing the new ceramsite are transported to the crusher through a conveyor for crushing, and the particle size after crushing is 5.5 mm; then the other small particles in the raw materials for preparing the new ceramsite are The materials and the crushed materials are put into the resonance mill or ball mill for grinding or ball milling respectively; finally, they enter the winnowing and classifying machine for winnowing. The machine is transported to the sto...

Embodiment 3

[0076] like figure 1 Shown, the preparation method of another kind of novel ceramsite of the embodiment of the present invention, comprises the following steps:

[0077] Step 1: Dry

[0078] The various raw materials for preparing the new ceramsite are transported to the dryer through a conveyor for drying, and dried until the moisture content is not higher than 3%, and then the raw materials are stored in the raw material warehouse for use;

[0079] Step 2: Shred

[0080] The bulk materials in the raw materials for preparing the new ceramsite are transported to the crusher through a conveyor for crushing, and the particle size after crushing is 10 mm; then the other small particle materials in the raw materials for preparing the new ceramsite are And the materials crushed by the crusher are respectively put into the resonance mill or ball mill for grinding or ball milling; finally, they enter the winnowing and classifying machine for winnowing. Store in the storage bin for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com